High speed railway two-line-to-four-line turnout zone bridge beam portion structure

A technology for high-speed railways and switch areas, applied in bridges, buildings, etc., can solve problems such as poor train safety and comfort, strong train dynamic response, and intensified ground dynamic response, so as to improve safety and comfort, improve power performance, reducing the effect of lateral misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

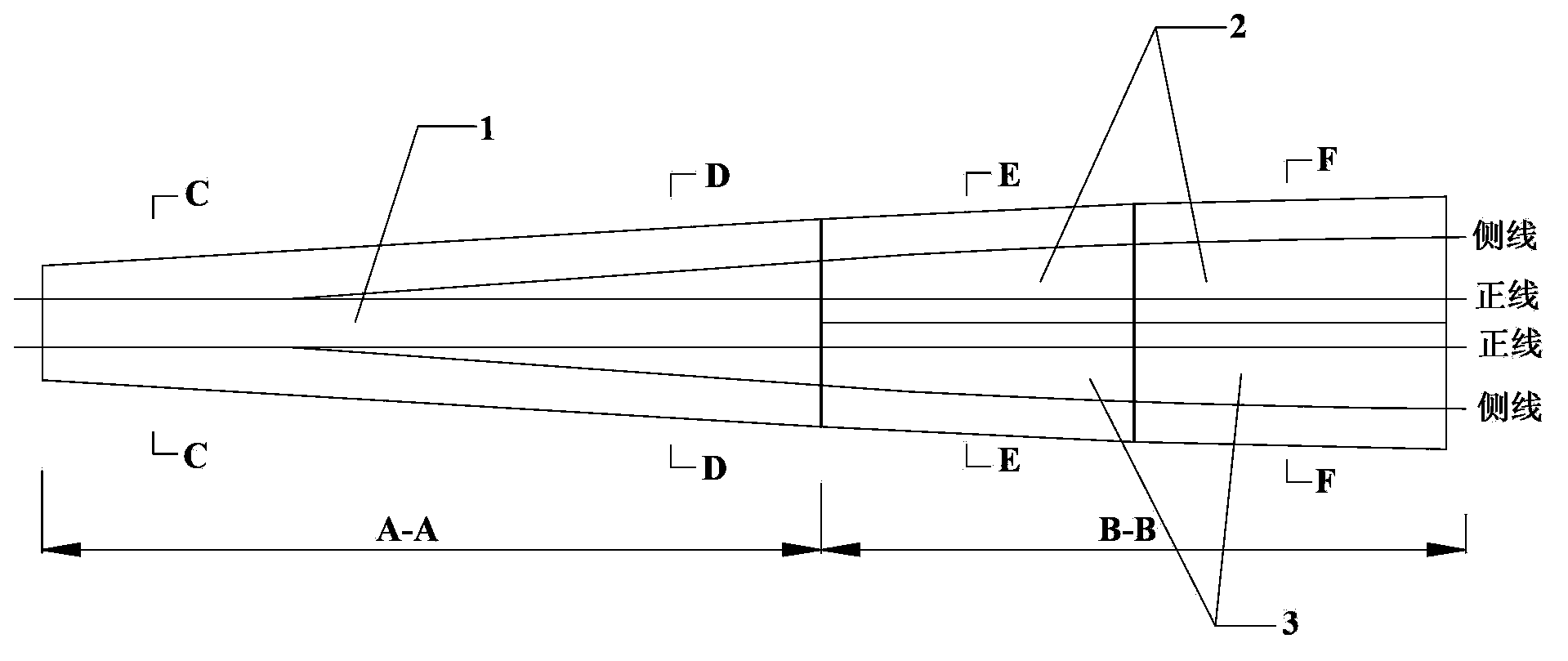

[0022] like figure 1 Shown: the bridge girder structure of the high-speed railway two-line-to-four-line turnout area, including the two-line to four-line turnout area A-A, and the area B-B where the line spacing changes after the switch; the two-line to four-line turnout area A-A) is changed The wide continuous beam (1) is formed; the area (B-B) where the line spacing changes behind the fork is distributed symmetrically with the center line, the left widened simply supported beam (2) and the right widened simply supported beam (3).

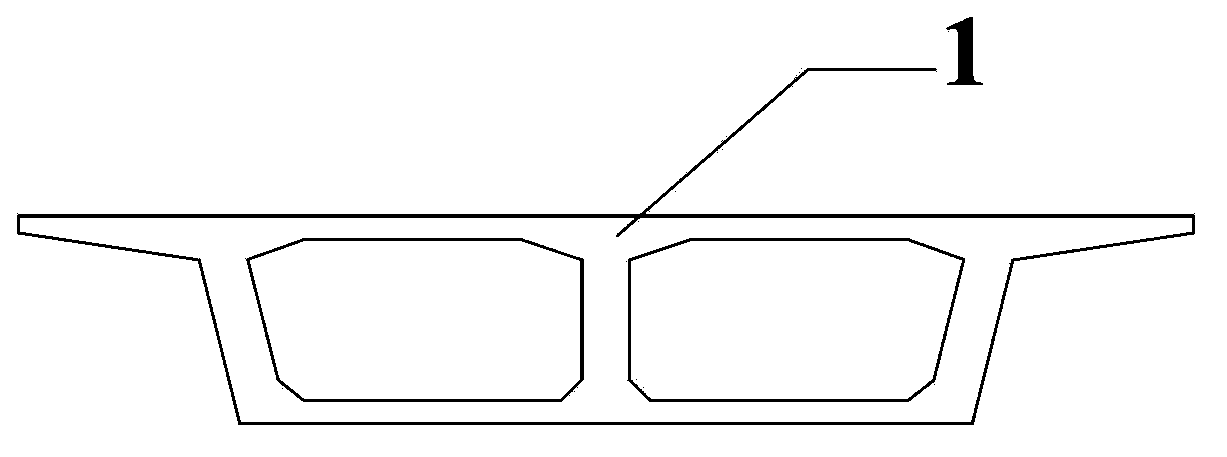

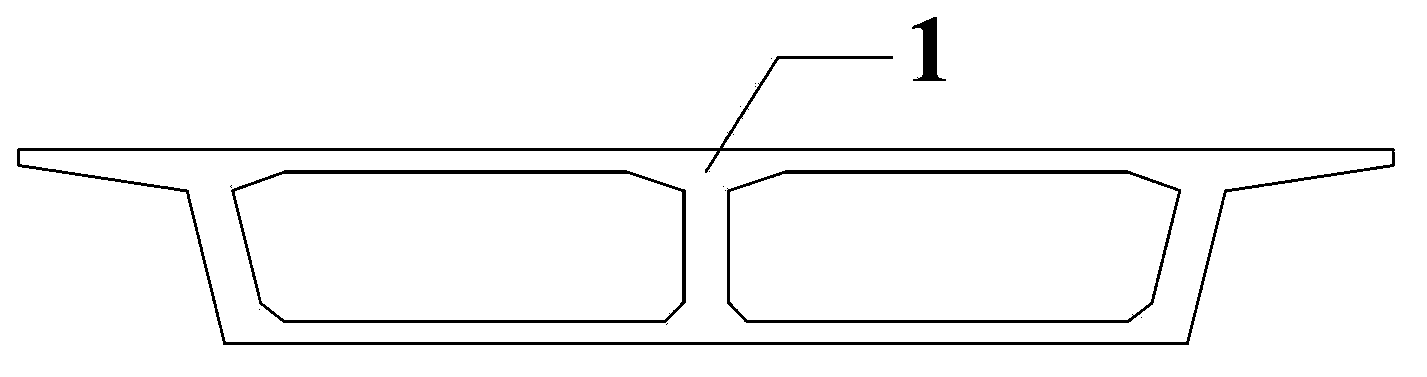

[0023] like Figure 2-4 As shown, the widening continuous beam 1 in the turnout area A-A of the two-line to four-line transformation mainly has two structural forms, one is a box girder with a single box and two chambers, and the other is a box girder with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com