hydraulic lifting dam

A lifting dam and hydraulic technology, which is applied in the direction of fluid pressure actuators, water conservancy projects, sea area projects, etc., can solve the problems of weak anti-flood impact ability, insufficient support strength of dam slab, and easy fatigue damage of hydraulic cylinders, etc., to achieve flood resistance The effect of strong water impact, sufficient lifting force and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

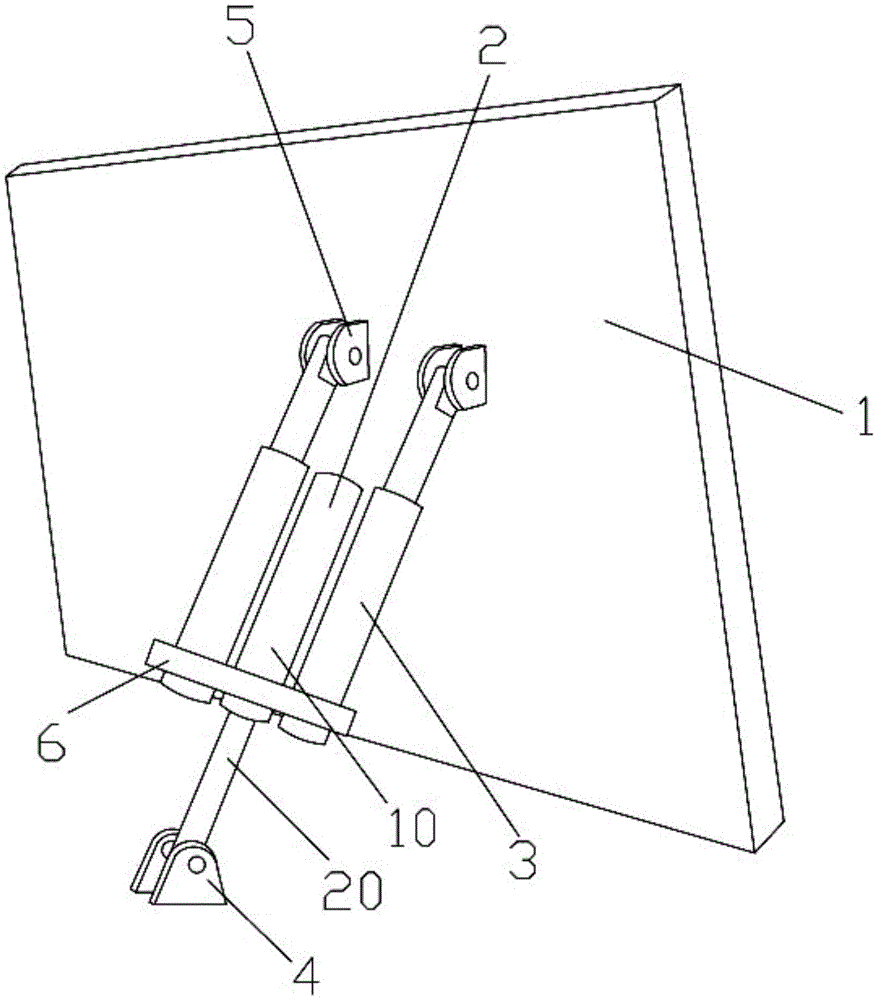

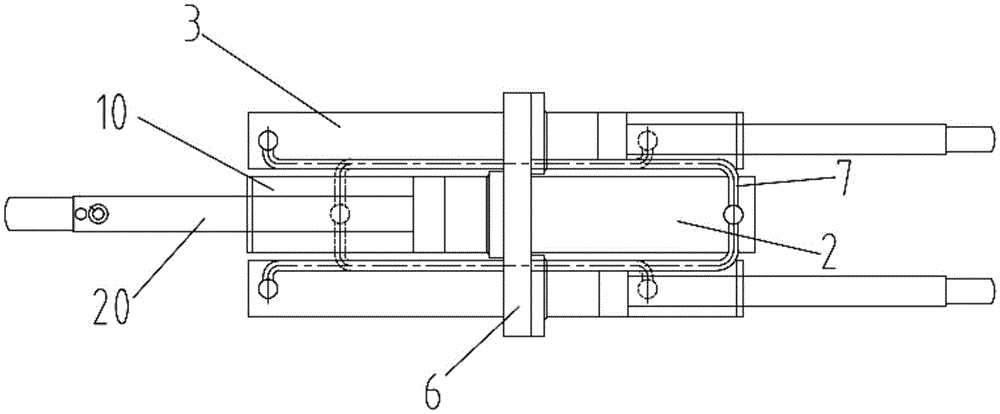

[0020] Hydraulic lifting dam of the present invention, as figure 1 As shown, the movable dam slab 1 is included, and the bottom end of the movable dam slab 1 is a movable hinge connection, which can rotate along the hinged shaft. On the backwater side of the movable dam 1, there is a hydraulic cylinder assembly supported by the movable dam 1 in the shape of a "herringbone", and the lifting control of the movable dam is realized through the expansion and contraction of the hydraulic cylinder. The hydraulic cylinder assembly is composed of multiple single-section hydraulic cylinders arranged in a row. The single-section hydraulic cylinder can ensure sufficient jacking oil pressure, strong jacking force, and quick response to lifting. The cylinder blocks 10 of the hydraulic cylinders are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com