Method for testing function of dual clutch assembly

A dual-clutch, clutch technology, applied in machine/structural component testing, mechanical component testing, machine gear/transmission mechanism testing, etc., can solve the problems of manual implementation of sensor consumption, time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

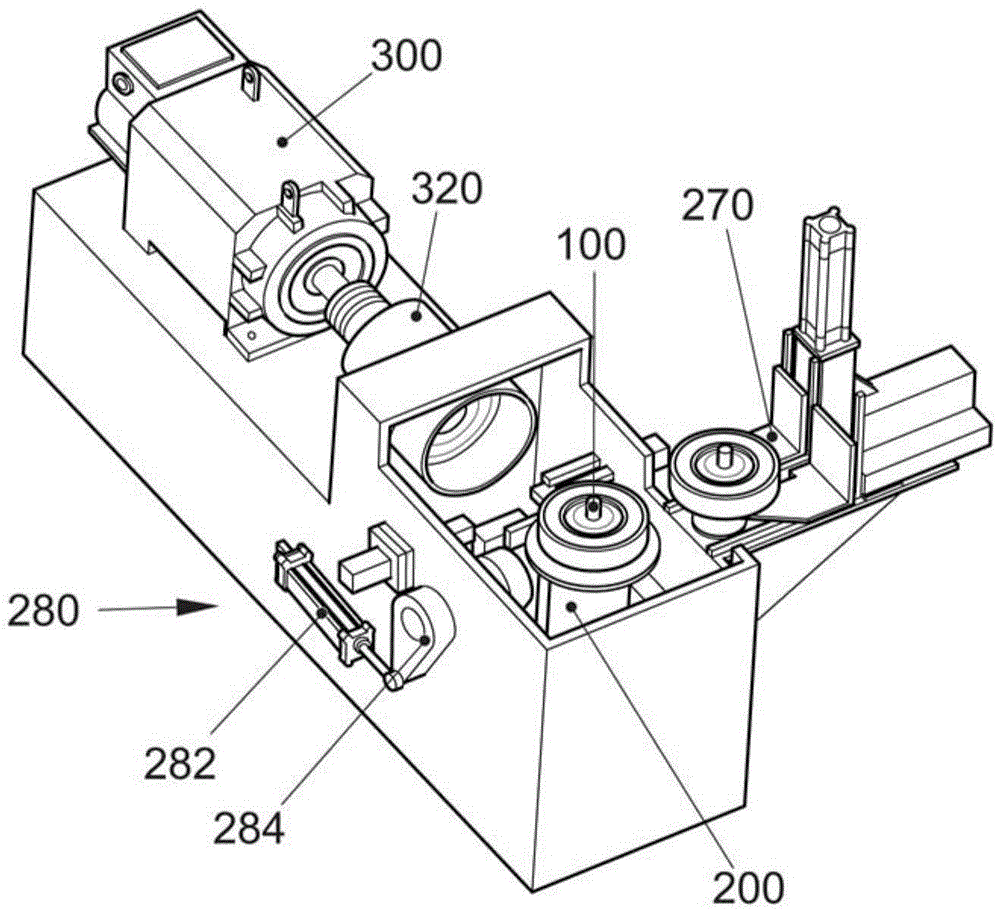

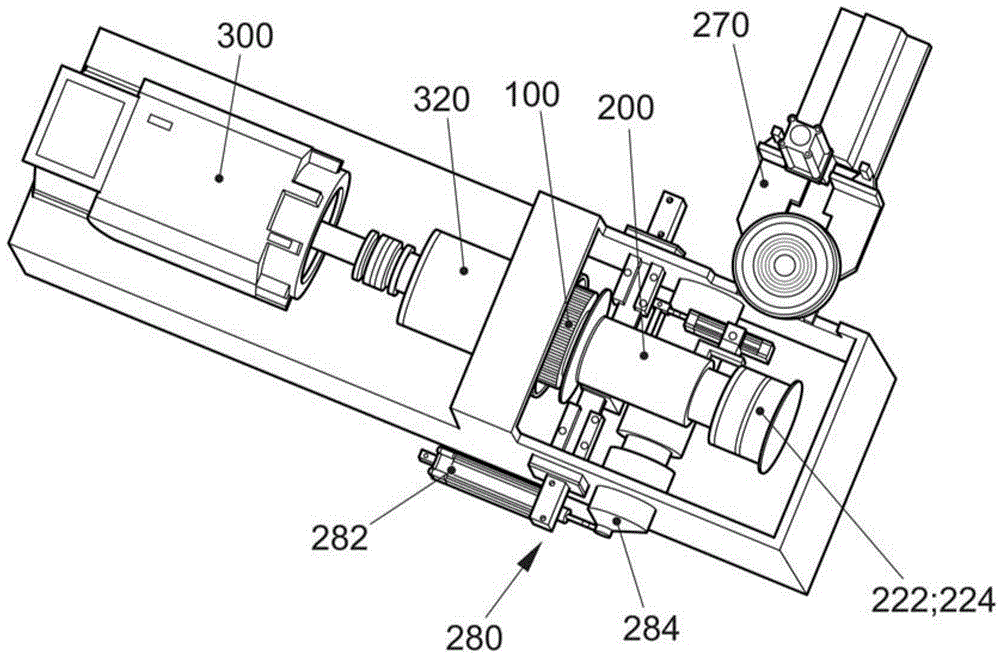

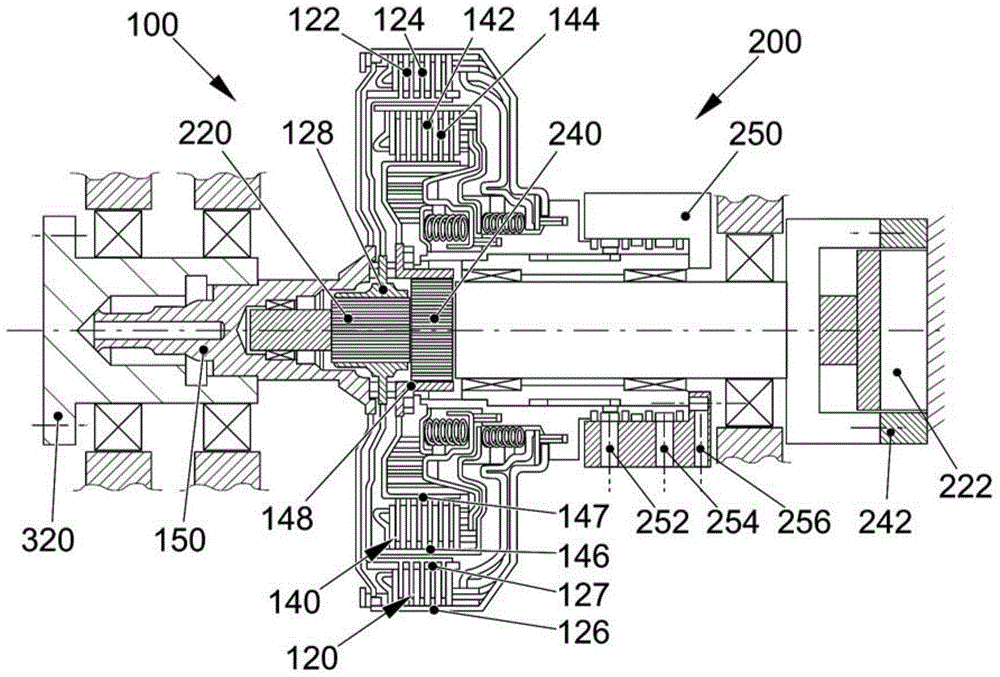

[0042] image 3 The dual clutch unit 100 is shown in the test position, that is to say placed on the test unit 200 and connected to a drive motor 300 not shown in detail. The dual clutch unit 100 has a first friction clutch 120 and a second friction clutch 140 which respectively comprise a set of outer friction plates 122 , 142 and a set of inner friction plates 124 , 144 . The outer friction plates 122 , 142 are connected to a common clutch input shaft 150 through outer friction plate supports 126 , 146 respectively. The inner friction plate supports 127, 147 are respectively connected with the hubs 128, 148, and the inner teeth of the hubs 128, 148 are sleeved on the corresponding input shafts of the gearbox when the dual clutch unit 100 is finally assembled in the gearbox.

[0043] In order to carry out the testing method according to the invention, the dual clutch unit 100 is instead fitted on testing shafts 220, 240, which are concentrically designed like the gearbox inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com