Fast calibration method of microwave high power passive distributor

A calibration method and high-power technology, applied in the direction of instruments, measuring devices, measuring electrical variables, etc., can solve the problems of large amount of data, time-consuming and computing resources, affecting the speed and efficiency of testing, and achieve high-precision and rapid calibration , taking into account the effect of precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

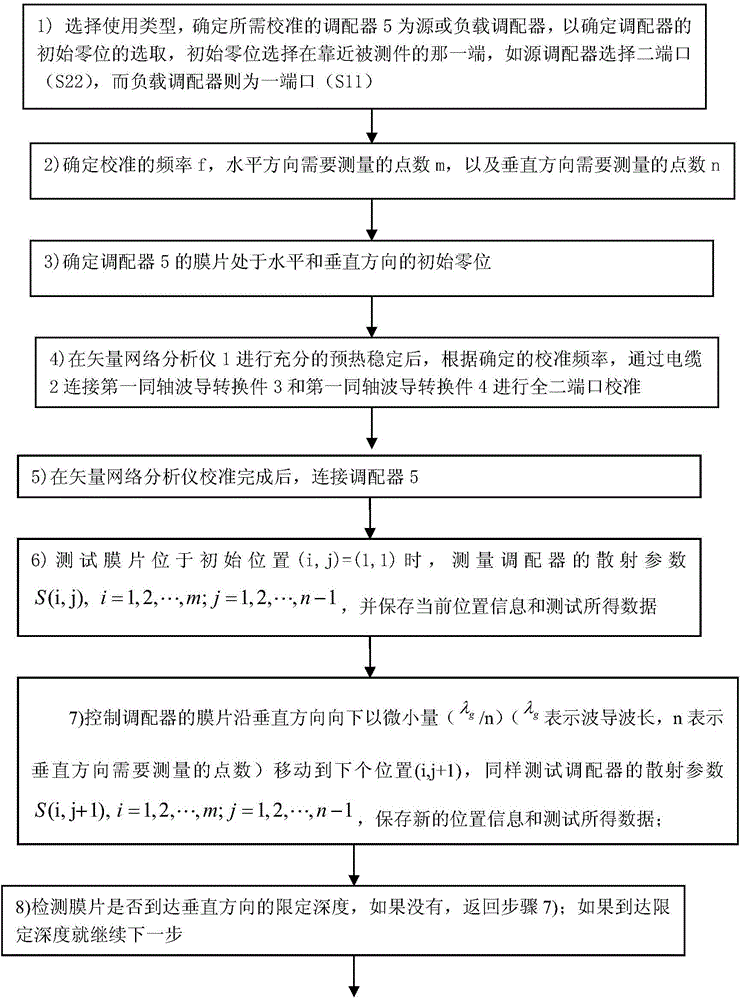

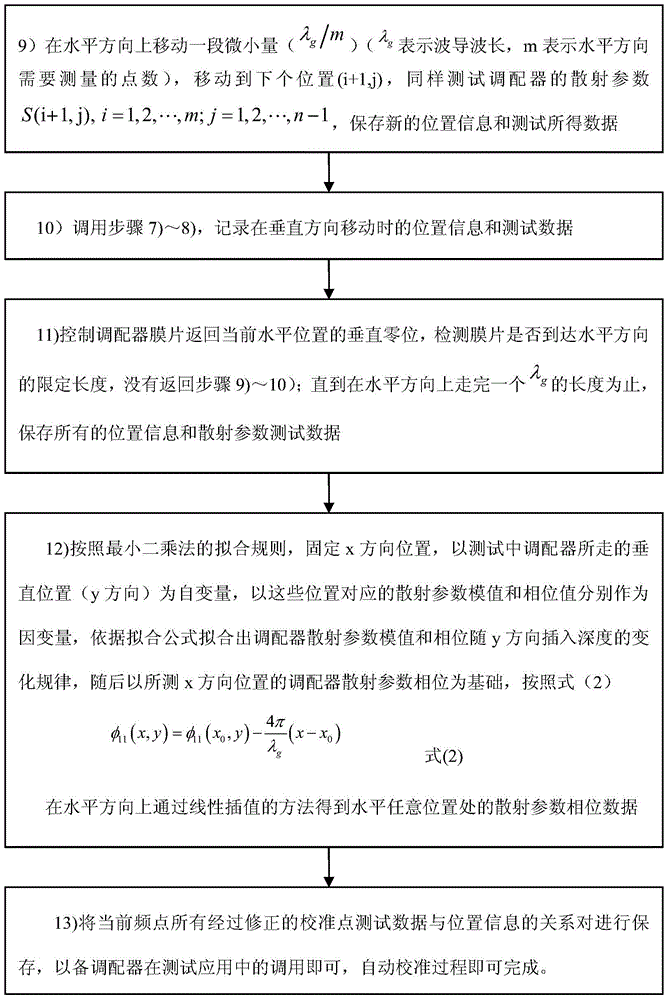

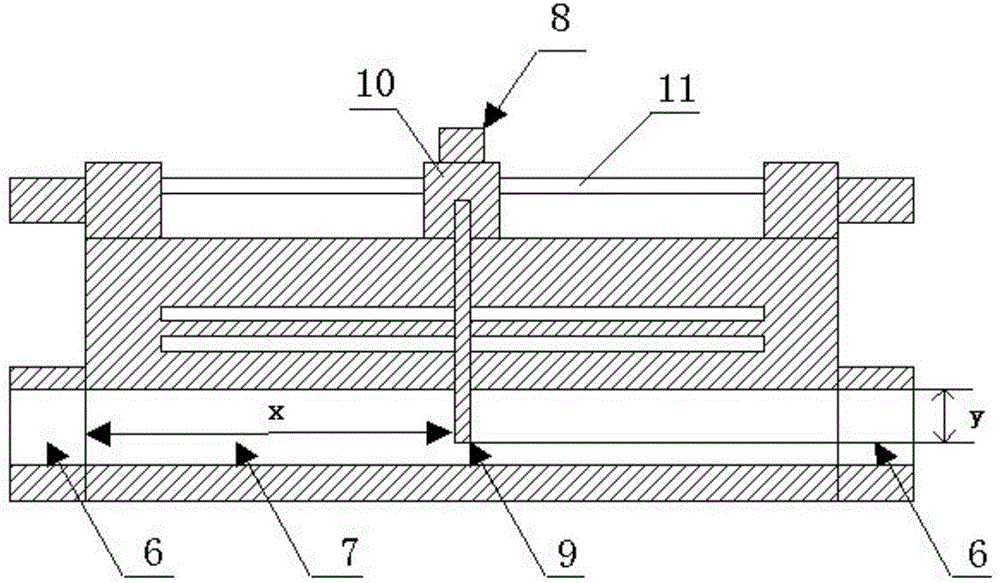

[0040] Such as figure 1 , image 3 As shown, the quick calibration method of microwave high-power passive adjuster includes the following steps:

[0041] 1) Select the type of use, and determine the adjuster 5 to be calibrated as a source or load adjuster to determine the selection of the initial zero position of the adjuster. The initial zero position is selected at the end close to the DUT, such as the source adjuster selection Two ports (S22), while the load leveler is one port (S11);

[0042] 2) Determine the calibration frequency f, the number of points to be measured in the horizontal direction m, and the number of points to be measured in the vertical direction n;

[0043] 3) Make sure that the diaphragm of the adjuster 5 is in the initial zero position in the horizontal and vertical directions;

[0044] 4) After the vector network analyzer 1 has fully warmed up and stabilized, according to the determined calibration frequency, connect the first coaxial waveguide con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com