Method for adjusting the coaxiality of the triangular door shaft column

An adjustment method and a gate shaft column technology, applied in the field of gates, can solve the problems of difficulty in setting out, poor accuracy, and difficulty in meeting mounting holes, etc., and achieve the effects of convenient construction, convenient operation, and rapid and accurate calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

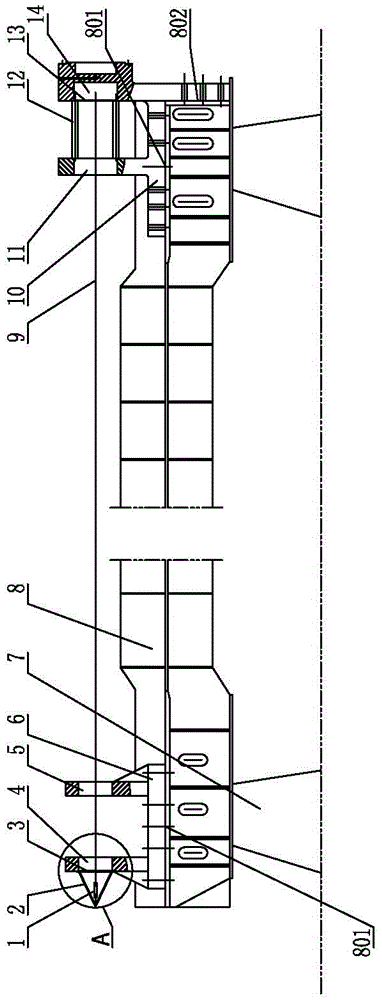

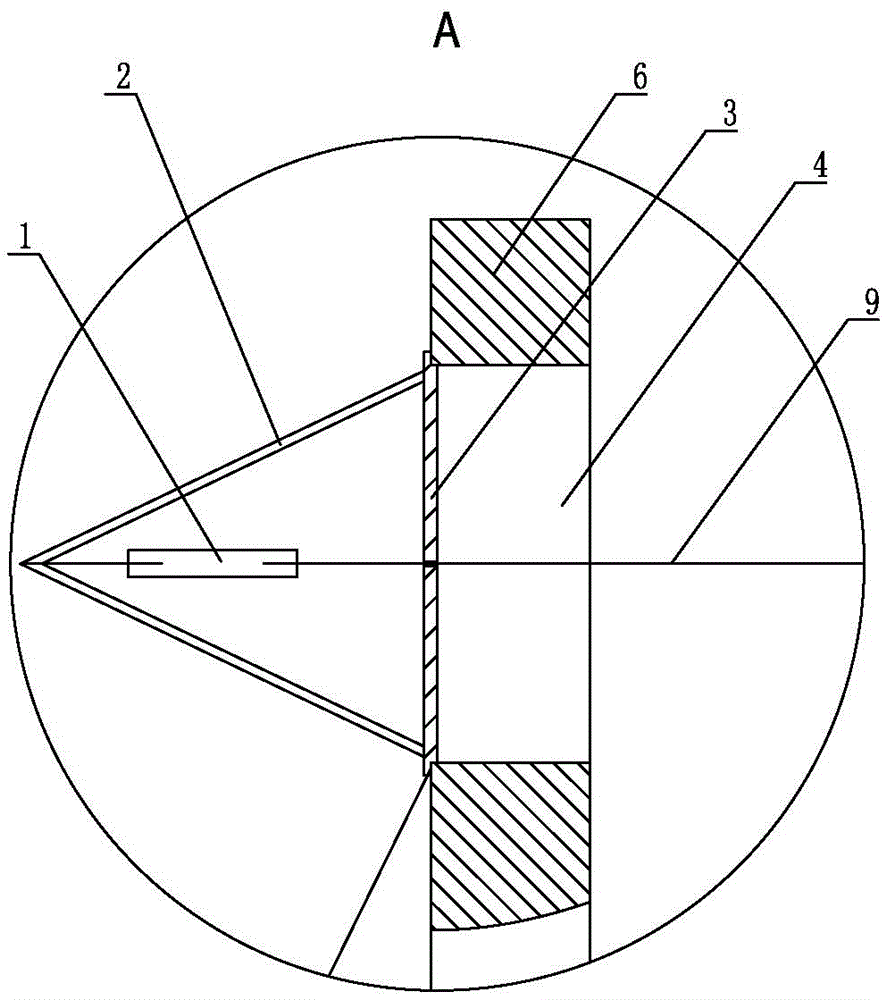

[0020] As shown in the figure, it is a method for adjusting the coaxiality of a triangular door shaft column, which includes the following steps:

[0021] 1) Place the end column 8 horizontally on the two support piers 7, so that the main installation surface of the end column 8 for installing the upper tie rod support 6 and the bottom pivot hinge seat 10 faces upward; measure with a level to make the end column 8 is used to install the main mounting surface 801 of the upper tie rod support 6 and the bottom pivot hinge seat 10 to be horizontal; the flatness of the main mounting surface 801 itself is guaranteed by prior machining, and in this step it is only necessary to calibrate the level. Can;

[0022] 2) Draw the central reference line on the symmetrical center of the upper surface of the end column 8, and put the side installation surface of the bottom pivot hinge seat 10 against the side installation surface 802 at the bottom of the end column 8, and the other installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com