Universal transfer switch installation components

A transfer switch and installation component technology, applied in the direction of electrical switches, electrical components, circuits, etc., can solve the problems of inconvenient replacement, visual fatigue, single shape, etc., and achieve the effect of saving time, easy identification, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, in order to overcome the lack of a single shape of the universal transfer switch installation component and at the same time ensure that it has multiple installation functions, the following structure is adopted:

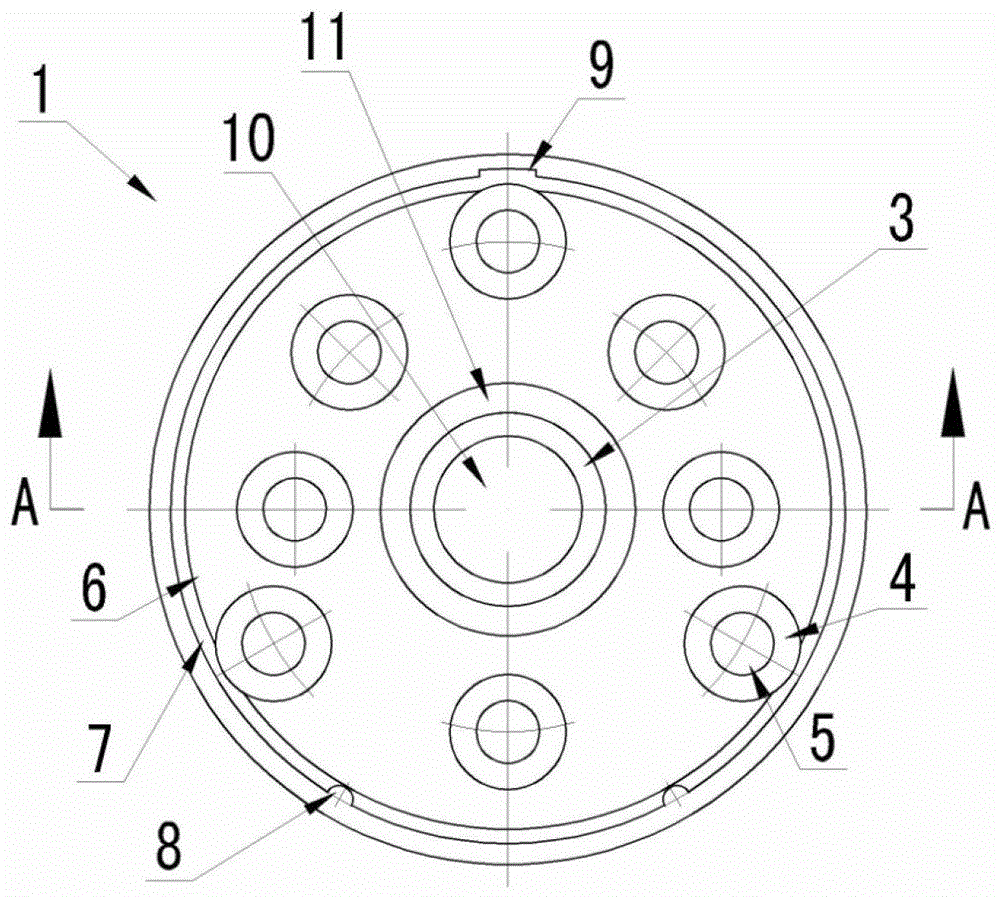

[0025] figure 1 It is a schematic structural diagram of the front view of the installation member of the universal transfer switch of the first embodiment.

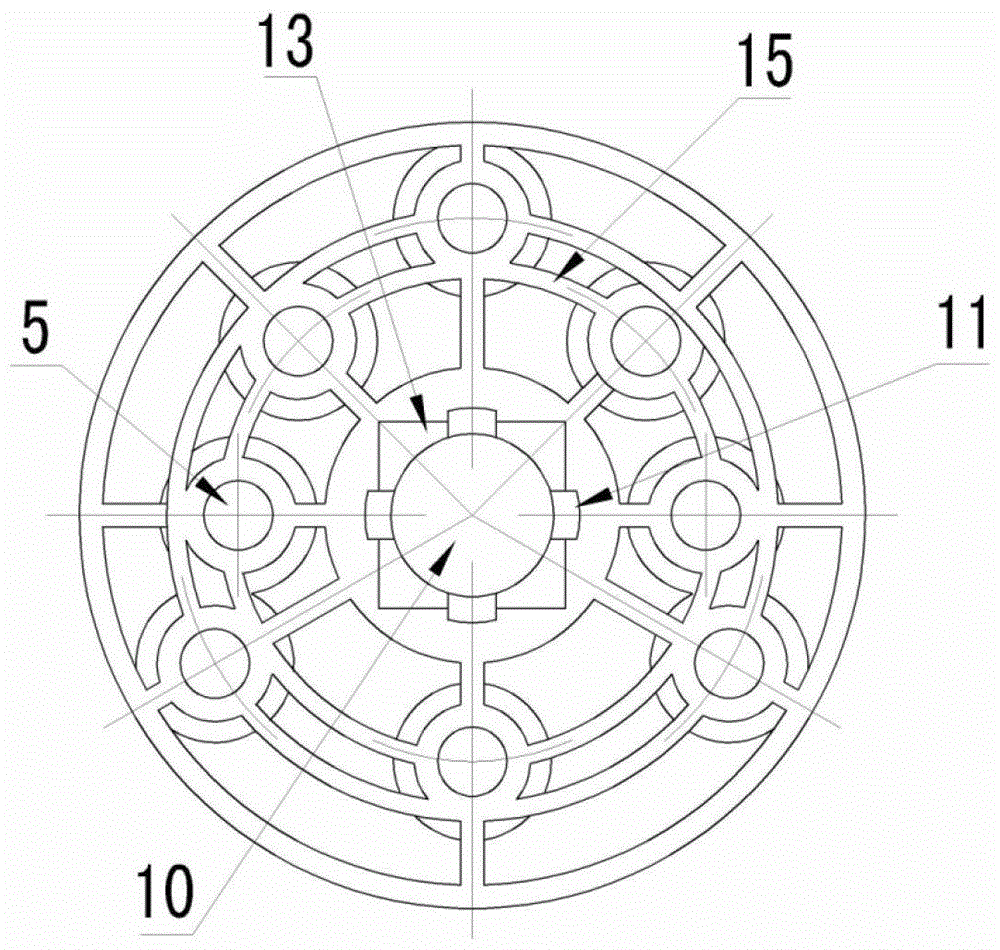

[0026] figure 2 It is a rear view structural schematic diagram of the universal transfer switch installation member of the first embodiment.

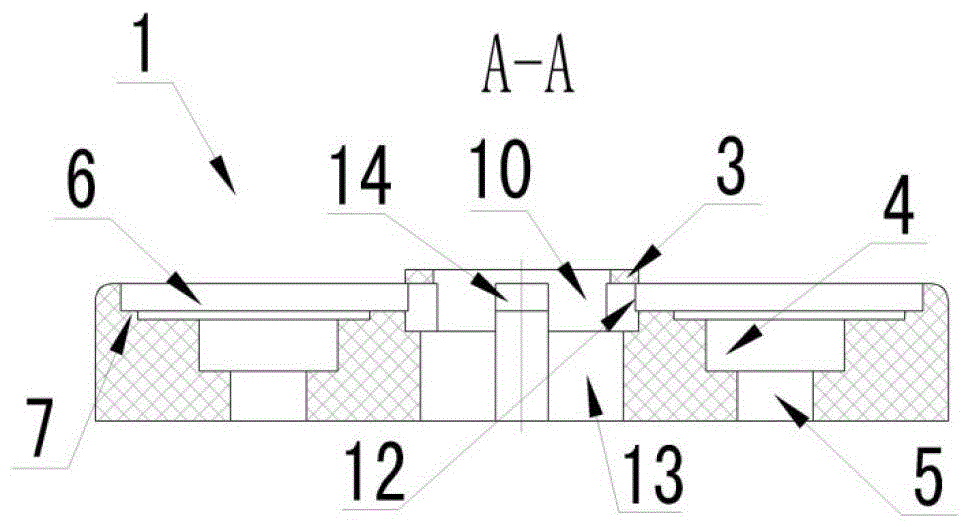

[0027] image 3 It is a schematic diagram of the cross-sectional structure along the A-A direction of the installation member of the universal transfer switch of the first embodiment.

[0028] Such as figure 1 , 2 As shown in and 3 , the universal transfer switch installation member 1 of Embodiment 1 includes a central boss 3 , an annular counterbore 6 , and installation counterbore 4 and installation through hole 5 arranged in an orderly...

Embodiment 2

[0033] In this embodiment, the installation member for the universal transfer switch described in the first example above is used.

[0034] Figure 4 It is a schematic diagram of the assembly and application of the universal transfer switch installation member and the plate in the second embodiment.

[0035] Figure 5 It is a schematic diagram of the assembly and application of the universal transfer switch mounting member and the universal transfer switch in the second embodiment.

[0036] Such as Figure 4 and Figure 5 As shown, during installation, the plate 16 is embedded in the annular counterbore 6 and is in contact with the annular rising step 7, and the side of the plate 16 can be embedded in one of the four rectangular through holes 12 to play a fixing role. The arc-shaped boss 8 is in contact with the edge positioning opening 18 of the name plate 16, which plays the role of positioning and preventing the name plate 16 from twisting, and the arc-shaped notch 9 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com