Lattice structure made by additive manufacturing

A network structure and additive manufacturing technology, which is applied in the direction of additive processing, dressing containers, dressing preparations, etc., can solve the problems that the stiffness of the mask cannot be well controlled, the patient is uncomfortable, and the effectiveness of the mask is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] a) mask

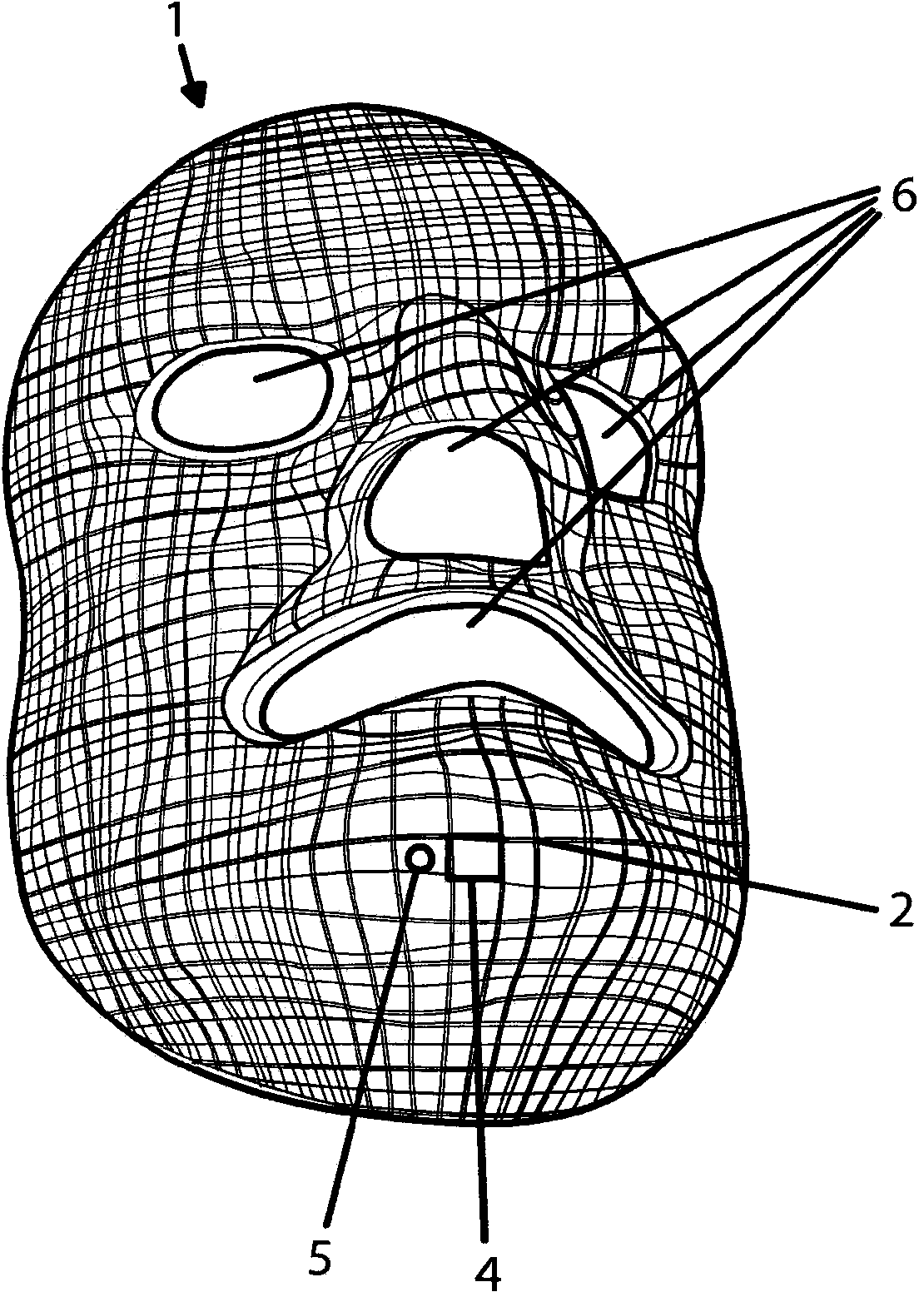

[0106] figure 1 A freeform structure ( 1 ) according to a particular embodiment of the invention is shown. The free-form structure described conforms to the surface of the human face. In particular, the free-form structure described is a mask that can be used for (burn) wound treatment. figure 1 The freeform structure shown comprises a network (2) impregnated in a polymeric material (5). The open network structure and the transparency of the polymer ensure that the freeform structures are transparent. The network is defined by unit cells (4) with dimensions between 1 and 20 mm. The network structure is provided with varying unit cell geometries and dimensions to control the stiffness of the freeform structure. Said mesh structure further comprises unimpregnated holes (6) for eyes, nose and mouth.

[0107] b) Overmolding process

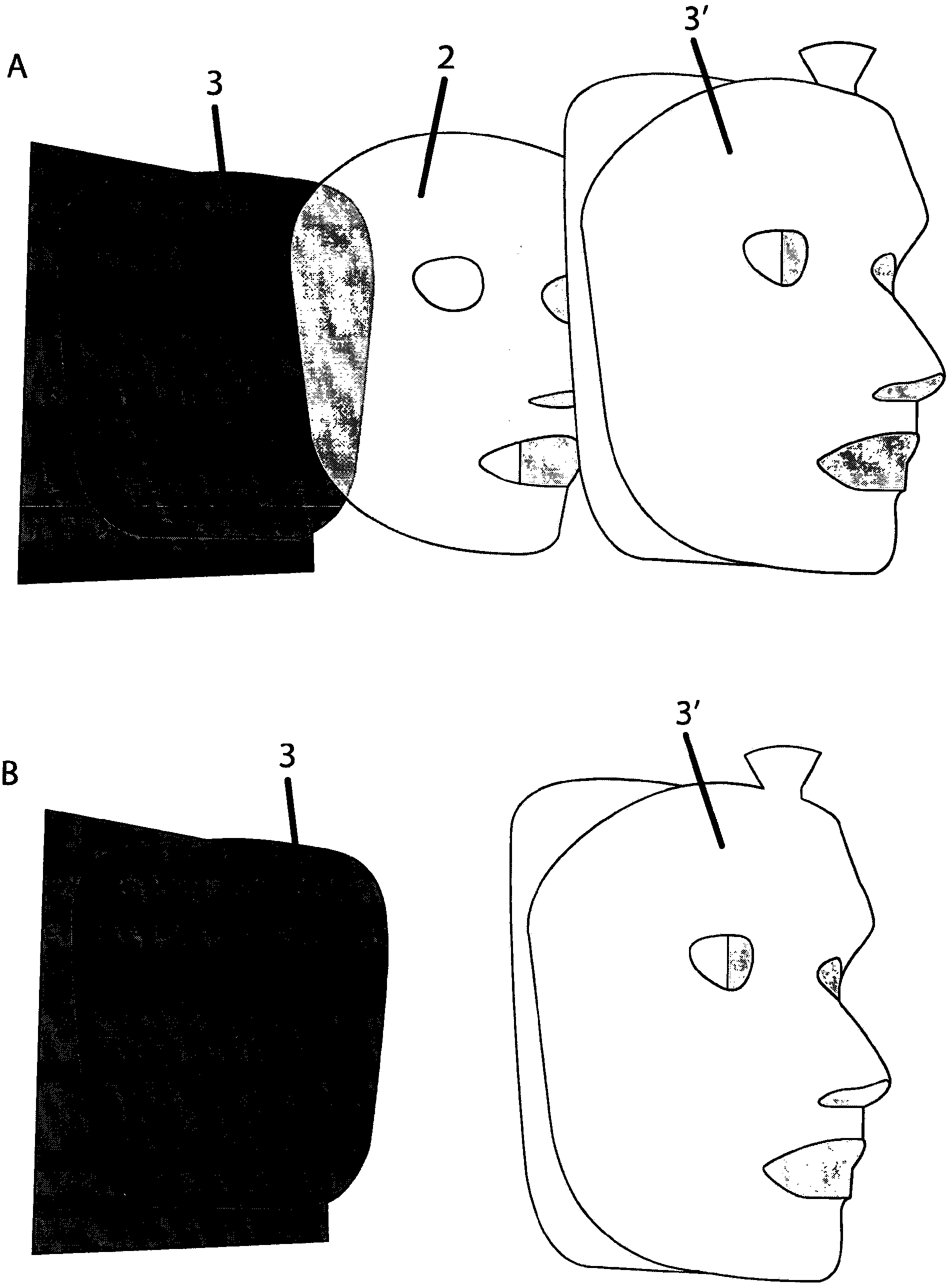

[0108]The methods provided herein for the manufacture of free-forming structures involve the step of impregnating a base ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com