Minitype farcie noodle machine

A noodle maker, miniature technology, used in dough extruders, dough handling, baking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

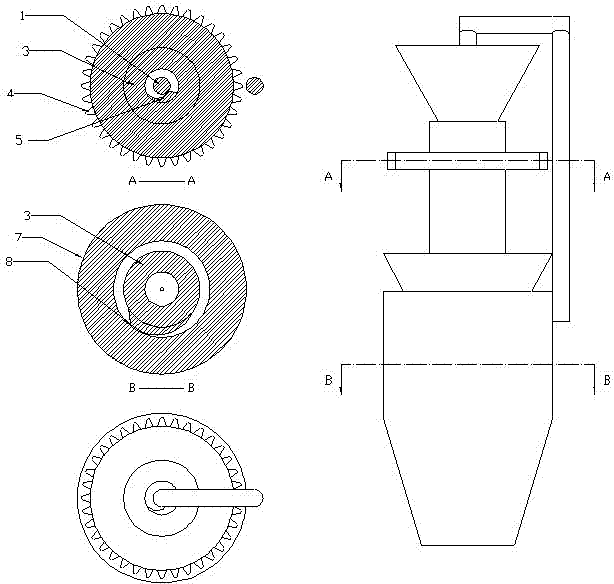

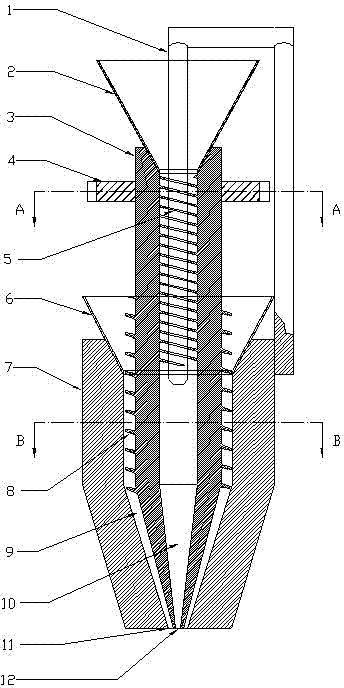

[0015] Such as figure 2 As shown, put the fabric in the upper end bucket 6 of the jacketed outer cylinder 7, and put the filling in the upper end of the threaded drum 3; rotate the transmission wheel 4 to drive the threaded drum 3, and the surface of the noodle bucket 6 The screw thread drum pushes the screw thread 8 and pushes it downward from the annular gap between the jacket outer drum 7 and the screw drum 3, and then passes through the surface channel 9 until the bottom end of the annular hole 11, extruding the annular hollow surface; The stuffing in the bucket 2 is pushed by the screw thread 5 in the threaded drum, and extruded downward from the annulus between the threaded drum 3 and the n-shaped shaft 1, through the stuffing channel 10, until the filling hole 12 at the lower end of the threaded drum 3 , Squeeze out the columnar stuffing and wrap it in the annular hollow noodles to make stuffed noodles.

Embodiment 2

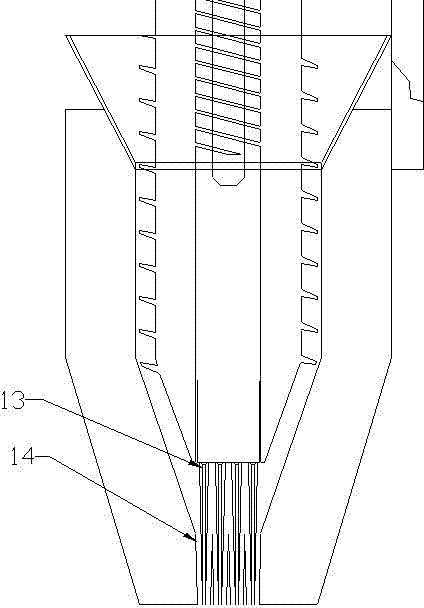

[0017] Such as figure 2 , image 3 As shown, put the fabric in the upper end bucket 6 of the jacketed outer cylinder 7, and put the filling in the upper end of the threaded drum 3; rotate the transmission wheel 4 to drive the threaded drum 3, and the surface of the noodle bucket 6 The screw thread 8 is pushed outside by the screw barrel, and it is extruded downward from the annulus between the jacket outer barrel 7 and the screw barrel 3, passing through the surface channel 9, until the bottom end of the multi-pipe distribution hole 14 is extruded out of the annular hollow Noodles; the stuffing in the stuffing bucket 2 is pushed by the screw thread 5 in the threaded drum, and it is extruded downward from the annular gap between the threaded drum 3 and the n-type shaft 1, through the stuffing channel 10, until the lower end of the threaded drum 3 The tube is distributed out of the filling holes 13, extrudes the columnar filling, and is wrapped in the annular hollow noodles to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com