Two-time cleaning processing method for tobacco stems

A processing method and technology for tobacco stems, which are applied in the field of secondary stem washing processing of tobacco stems, can solve the problems of insufficient moisture increase, uneven width of cut stems, miscellaneous gas, irritating effects, etc. Proportion, improved safety and economy, improved cut stem quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

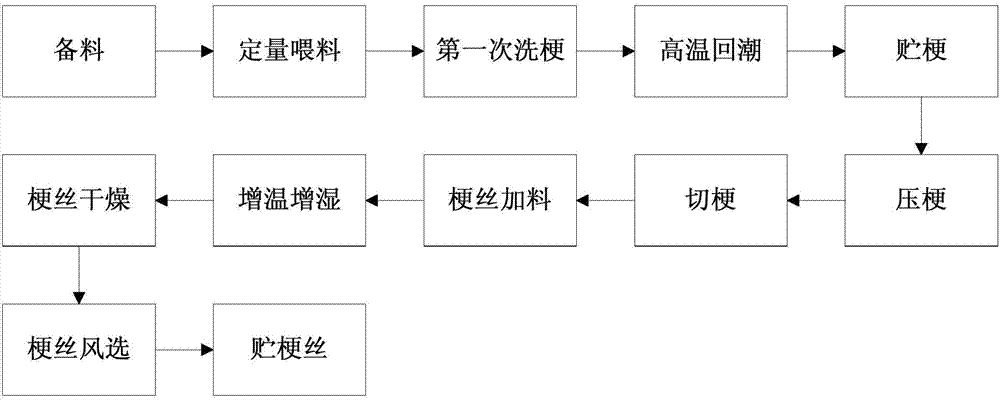

[0091] Tobacco stem formula 1500kg. Its processing method comprises the following steps:

[0092] 1. The first stem washing: send the quantitatively fed tobacco stems to the stem washing machine, the frequency of the water pump circulation motor can be controlled at 22Hz, and the water temperature can be controlled at 50°C-60°C.

[0093] 2. High temperature regain: send the tobacco stems after the first washing to the dampening machine for temperature increase and humidification, and the temperature of the outlet tobacco stems can be controlled at 60°C-70°C.

[0094] 3. Storage of stems: Send the tobacco stems after high-temperature moisture regain to the stem storage cabinet for storage, and the storage time can be controlled within 2-24 hours.

[0095] 4. Stalk pressing: Send the stored tobacco stems to a pressing machine for pressing, and the pressing gap of the stems can be controlled at 0.7-1.2 mm.

[0096] 5. The second stem washing: send the compressed tobacco stems t...

no. 2 Embodiment

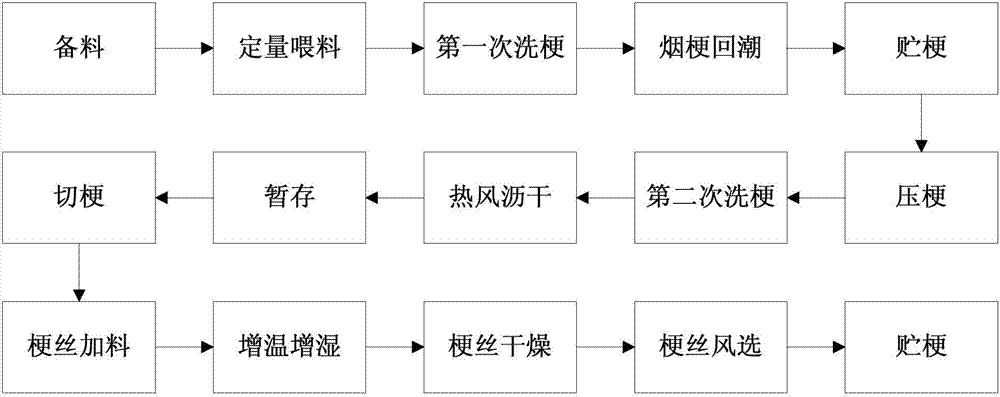

[0106] Tobacco stem formula 1500kg. Its processing method comprises the following steps:

[0107] 1. The first stem washing: send the quantitatively fed tobacco stems to the stem washing machine, the frequency of the water pump circulation motor can be controlled at 22Hz, and the water temperature can be controlled at 50°C-60°C.

[0108] 2. High temperature regain: send the tobacco stems after the first washing to the dampening machine for temperature increase and humidification, and the temperature of the outlet tobacco stems can be controlled at 60°C-70°C.

[0109] 3. Storage of stems: Send the tobacco stems after high-temperature moisture regain to the stem storage cabinet for storage, and the storage time can be controlled within 2-24 hours.

[0110] 4. Stalk pressing: Send the stored tobacco stems to a pressing machine for pressing, and the pressing gap of the stems can be controlled at 0.7-1.2mm.

[0111] 5. The second stem washing: send the compressed tobacco stems to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com