Online continuously cast billet surface strengthening quenching treatment equipment system and process

A surface strengthening and continuous casting billet technology, applied in quenching devices, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of low qualification rate, increased cost, low production efficiency, etc., to improve surface quality, improve stability, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

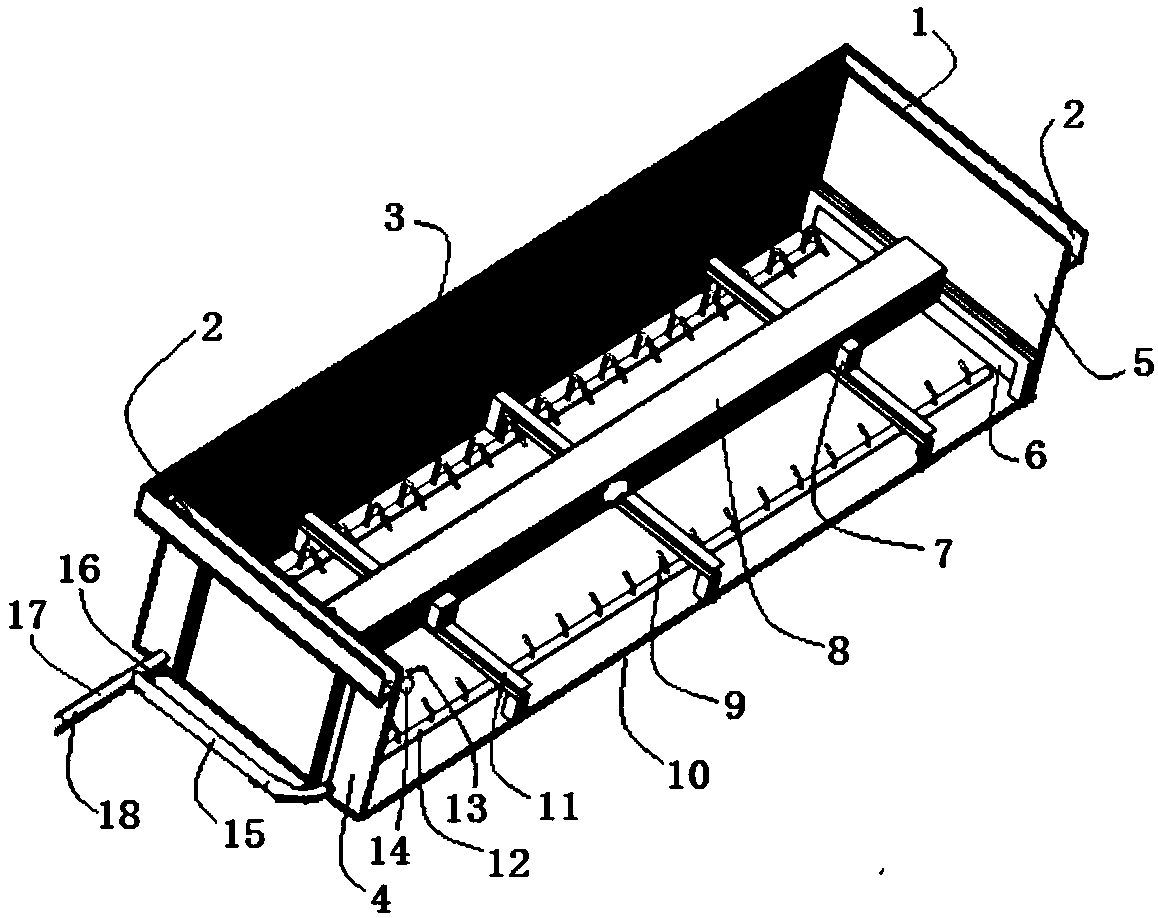

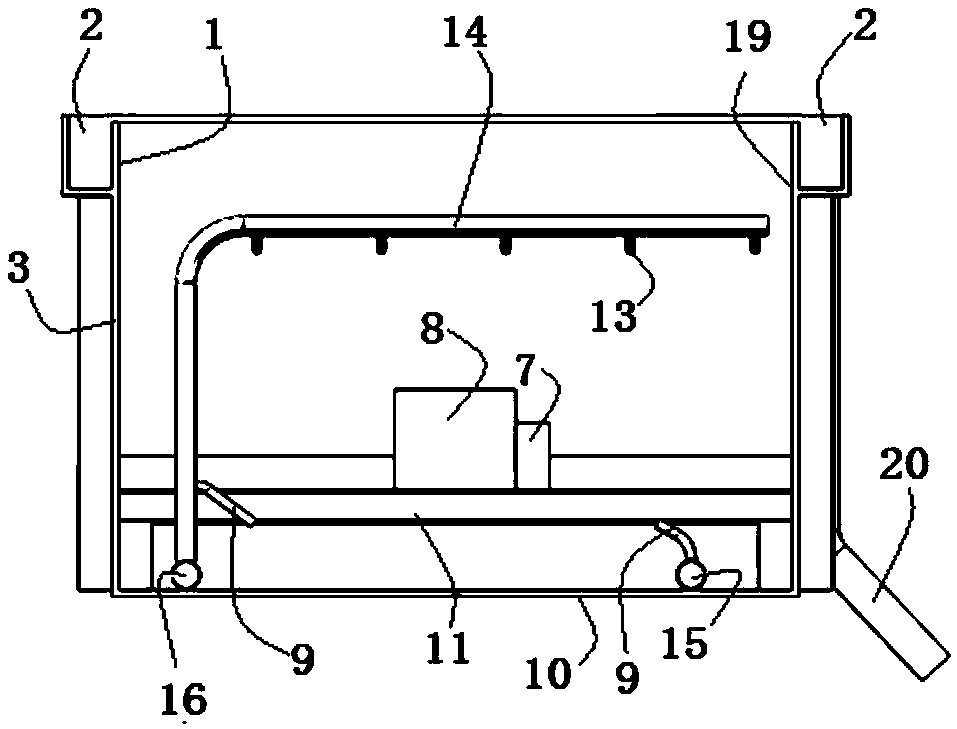

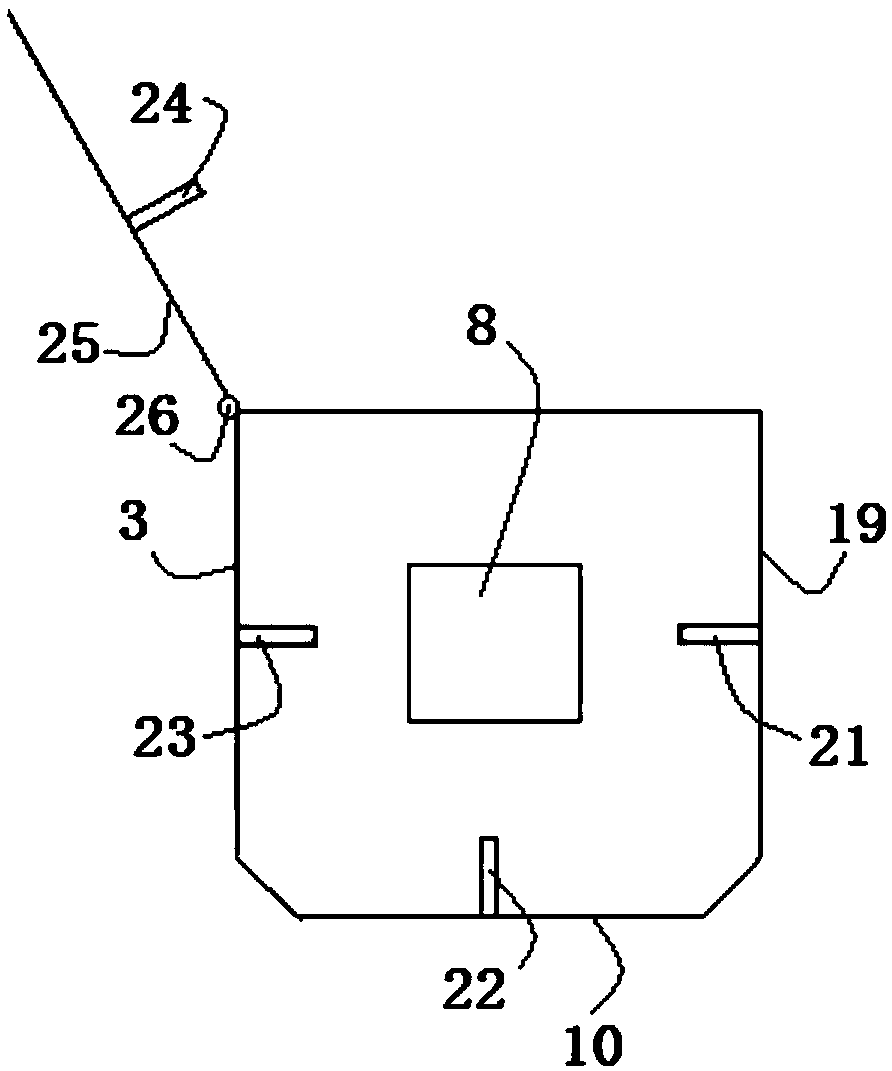

[0029] Below with the accompanying drawings ( Figure 1-Figure 3 ) to illustrate the present invention.

[0030] figure 1 It is a structural schematic diagram of the quenching tank in the online continuous casting slab surface strengthening quenching treatment equipment system of the present invention. figure 2 yes figure 1 Schematic diagram of the left view structure of the quenching tank. image 3 It is a schematic diagram of the four-sided single-row water spray arrangement in the quenching tank. Such as Figure 1 to Figure 3 As shown, an online continuous casting slab surface strengthening quenching treatment equipment system, a quenching tank 1 is set between the continuous casting slab roller table of the continuous casting production line and the hot delivery process or slow cooling and heat preservation process. Described quenching tank comprises tank body, is provided with overflow groove 2 ( figure 1 The middle is a notch annular overflow tank arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com