Automatic classification device of die casings

An automatic classification and die-casting technology, applied in the field of mechanical equipment, can solve the problems of high operating cost, single function, waste of processing time, etc., achieve the effect of saving labor and time, simple operation method, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The die-casting automatic classification device in the embodiment of the present invention is set on the die-casting production and processing line, including a frame, a controller installed on the frame and used to detect the parameters of the die-casting parts, a drive mechanism electrically connected to the controller, and a device for receiving and A sorting table for conveying die castings, the sorting table includes a fixed table and a turning table that can be folded relative to the fixed table to change the conveying direction of the die casting, and the turning table is connected to the driving mechanism;

[0050] The controller determines whether or not to send a control signal to the driving mechanism according to the currently detected parameters of the die casting to drive the reversing table to turn over relative to the fixed table, so as to realize the classification of the die casting.

[0051] It can be understood that the fixed table and the flipping ta...

Embodiment 2

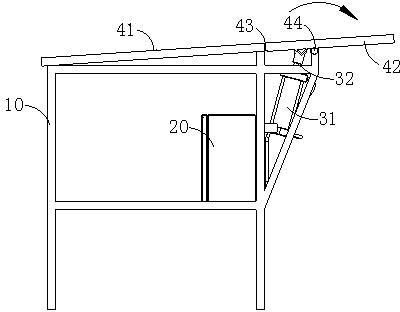

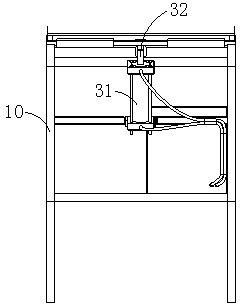

[0057] Such as Figure 1 to Figure 3 Shown is the third embodiment of the die-casting automatic classification device according to the embodiment of the present invention. The die-casting automatic classification device is arranged on the die-casting production and processing line, including a frame 10, a controller 20 arranged on the frame 10 and used for detecting die-casting parameters, a drive mechanism electrically connected to the controller 20, and a device for receiving And transport the sorting workbench of die-casting parts, the sorting workbench includes the fixed platform 41 and the overturning platform 42 that can be turned over and connected with each other, the two are connected by the first living hinge 43, the fixed platform 41 is arranged on the frame 10, and the overturning platform 42 Connect with drive mechanism. The driving mechanism of this embodiment is an air cylinder.

[0058] In this example, if figure 1 As shown, the cylinder includes a cylinder ...

Embodiment 3

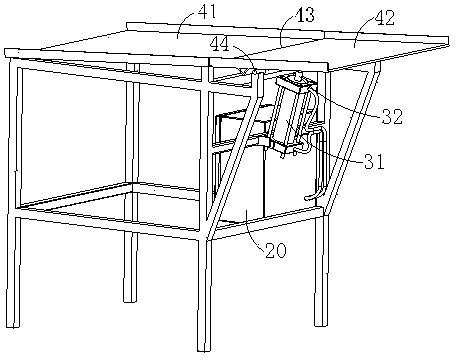

[0060] Such as Figure 4 to Figure 6 Shown is the third embodiment of the die casting automatic sorting device according to the embodiment of the present invention. Similarly, the die-casting automatic classification device is arranged on the die-casting production and processing line, including a frame 10, a controller 20 arranged on the frame 10 and used to detect die-casting parameters, a drive mechanism electrically connected to the controller 20, and A sorting workbench for sorting die castings. The sorting workbench includes a fixed platform 41 and an overturning platform 42 that can be turned over and connected to each other. The platform 41 is arranged on the frame 10, and the turning platform 42 is connected to the frame 10 through the second living hinge 44, and is connected to the driving mechanism at the same time. The driving mechanism of this embodiment is an air cylinder. It should be noted that the "contact point" here is not just a point, but from the side s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com