Installation and adjustment tooling and method for electromagnetic clutch of large-scale heavy-duty equipment

An electromagnetic clutch, installation and adjustment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems affecting the measurement and adjustment, and achieve the effect of avoiding heavy weight, convenient disassembly and measurement, reliable single action and linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical features and functions of the present invention in detail and realize them according to the content of this specification, the implementation of the present invention will be further described below in conjunction with the accompanying drawings.

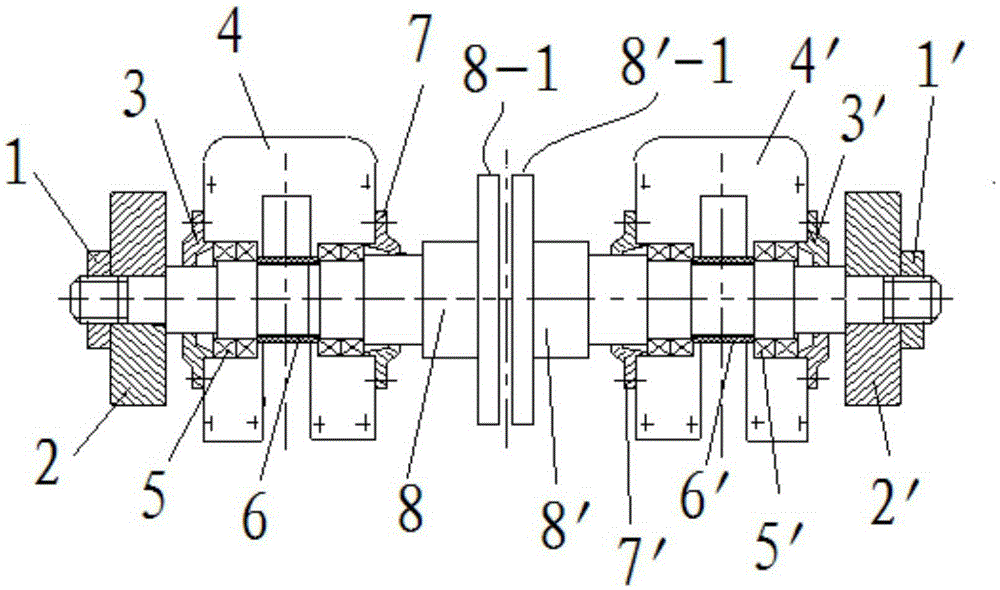

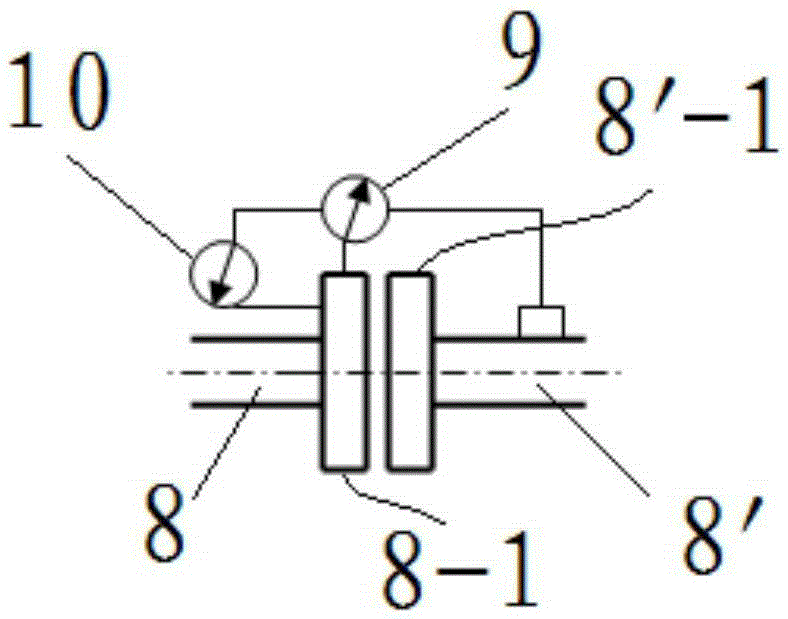

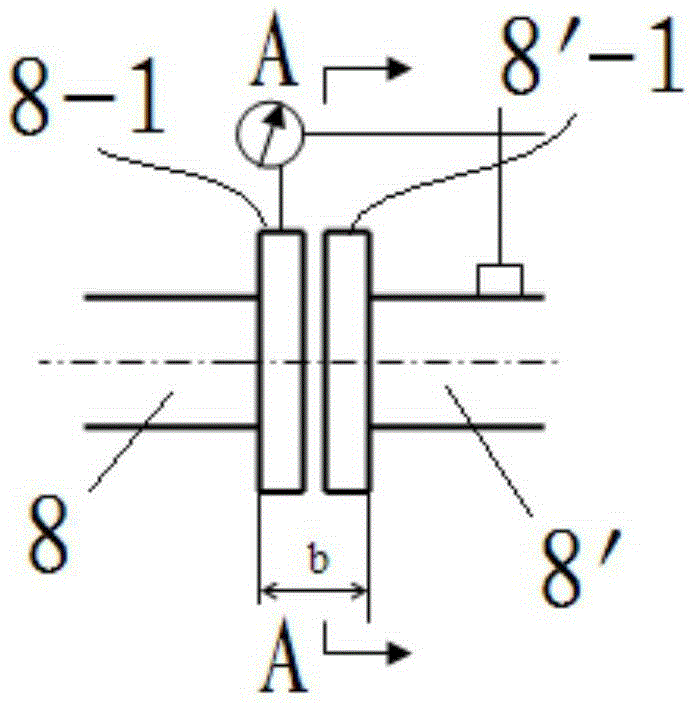

[0040] see figure 1, a large-scale heavy-duty equipment electromagnetic clutch installation and adjustment tooling of the present invention, the large-scale heavy-duty equipment has a drive motor and a reducer, one end of the electromagnetic clutch is connected to the output shaft of the drive motor, and the other end is connected to the input shaft of the reducer , when the electromagnetic clutch is combined, the torque of the driving motor can be transmitted to the reducer; the rotor of the driving motor is supported by a pair of sliding bearings arranged on the ground, and the bearing housings 4 of the two sliding bearings are fixed on the foundation by anchor bolts , the reducer casing 4'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com