Output mechanism for water meter movement impeller boxes

A technology of output mechanism and core, which is applied in the direction of conveyor objects, transportation and packaging, metal processing, etc., can solve the problems of poor assembly quality and uniformity, low work efficiency, easy injury, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

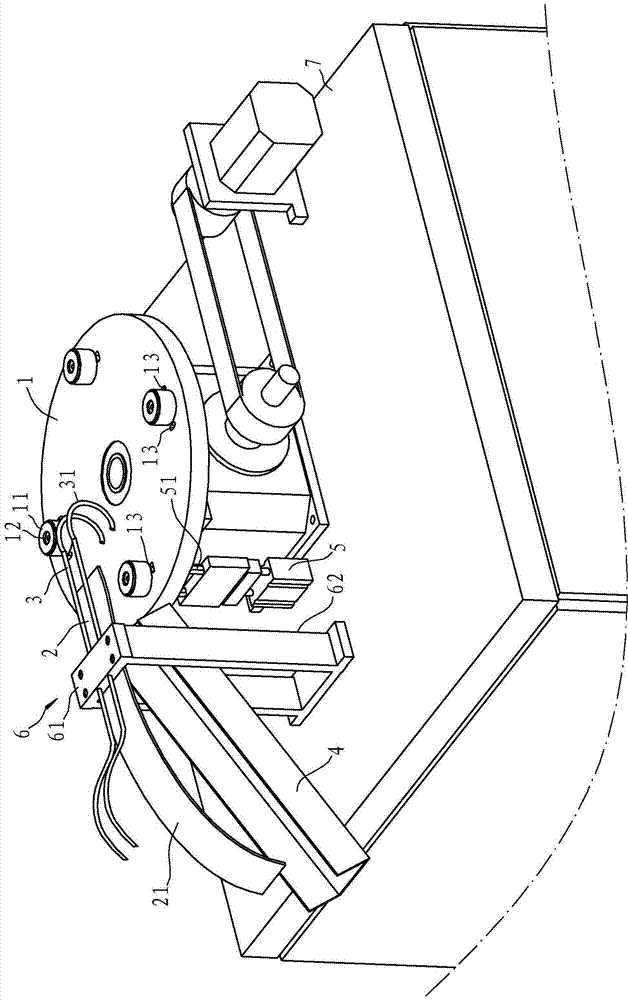

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

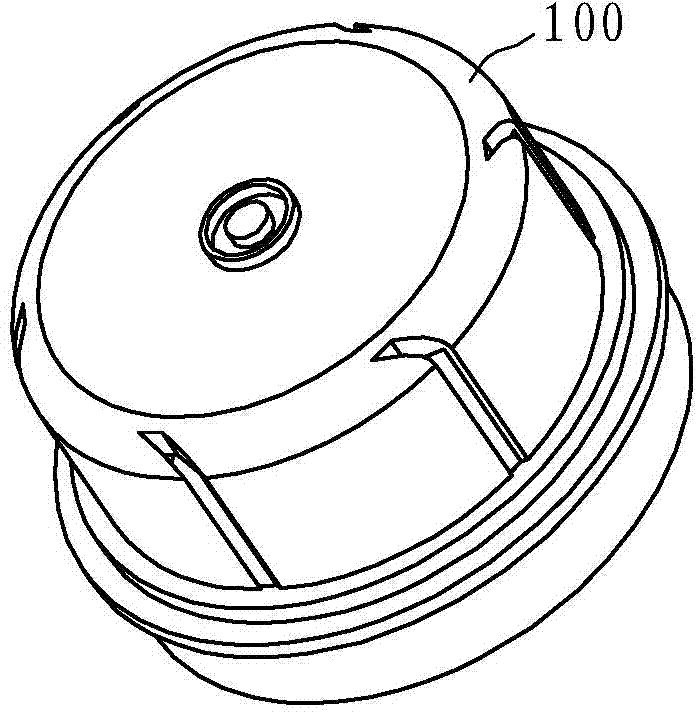

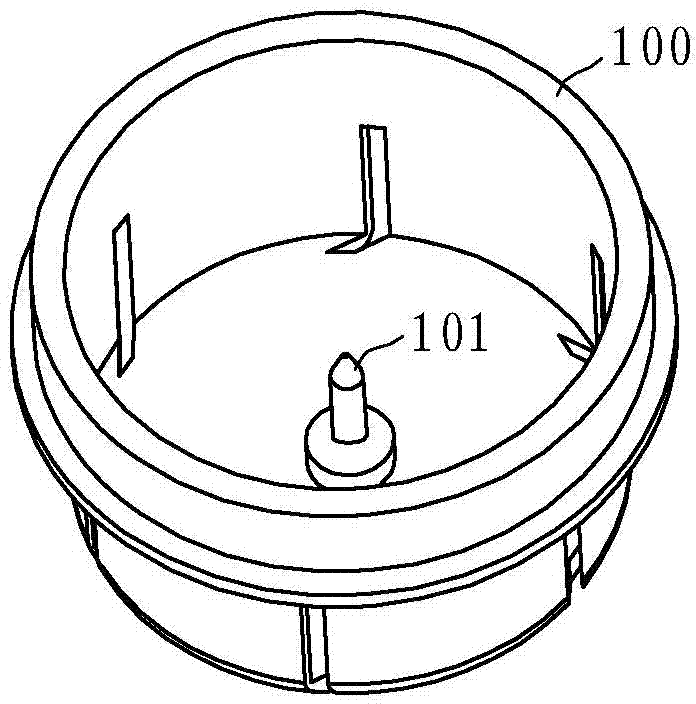

[0023] Such as image 3 and Figure 4 As shown, the output mechanism of the water meter movement leaf in this embodiment includes a worktable 7, a rotating disk 1, an ejection cylinder, a bracket 6, an air blowing mechanism 3, a baffle plate 2 and an output channel 4. The rotating disk 1 is arranged on the worktable 7 and can rotate intermittently under the drive of the motor 8. The upper end surface is evenly arranged along the circumferential direction with four mounting seats 11 for the leaf joint cover. The middle part of the mounting seat 11 has a The hollow channel 12 where the tip is inserted, and the rotating disc 1 is provided with through holes 13 on both sides of the mounting base 11 .

[0024] The ejector cylinder is located on the worktable 7, and the upper end has a push rod 51 that can stretch out the through hole 13 of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com