A method for improving the distribution of sic particles in magnesium matrix composites under the action of a low-voltage pulsed magnetic field

A composite material and low-voltage pulse technology, which is applied in the field of improving the distribution of SiC particles in magnesium-based composite materials, can solve the problems of less research and achieve the effect of simple process, low cost and investment, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

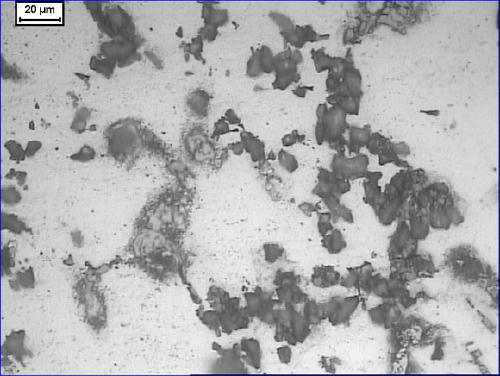

Embodiment 1

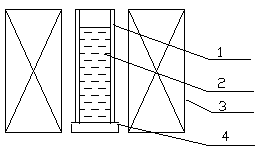

[0044] First, SiC particles are added to the magnesium alloy melt, stirred evenly, and then the alloy melt is poured into the mold placed in the pulse magnetic field solidification device, so that the composite material melt is completely solidified under the action of the pulse magnetic field; wherein, the magnetic field voltage is 150V, the frequency is 2.5Hz, the pouring temperature of the melt is 680°C, and the mold preheating temperature is 200°C.

Embodiment 2

[0046] First, SiC particles are added to the magnesium alloy melt, stirred evenly, and then the alloy melt is poured into the mold placed in the pulse magnetic field solidification device, so that the composite material melt is completely solidified under the action of the pulse magnetic field; wherein, the magnetic field voltage is 200V, the frequency is 5Hz, the pouring temperature of the melt is 620°C, and the mold preheating temperature is 600°C.

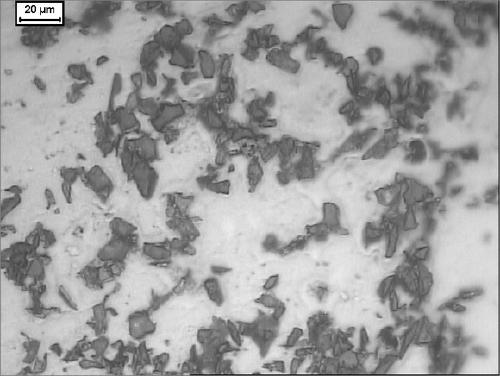

Embodiment 3

[0048] First, SiC particles are added to the magnesium alloy melt, stirred evenly, and then the alloy melt is poured into the mold placed in the pulse magnetic field solidification device, so that the composite material melt is completely solidified under the action of the pulse magnetic field; wherein, the magnetic field voltage is 250V, the frequency is 10Hz, the pouring temperature of the melt is 650°C, and the mold preheating temperature is 400°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com