A zero-stress seam width adaptive roof seam waterproofing system and its construction method

An adaptive, reserved seam technology, applied to roofs, roof cladding, and roofs using flat/curved panels, etc., can solve problems such as poor waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

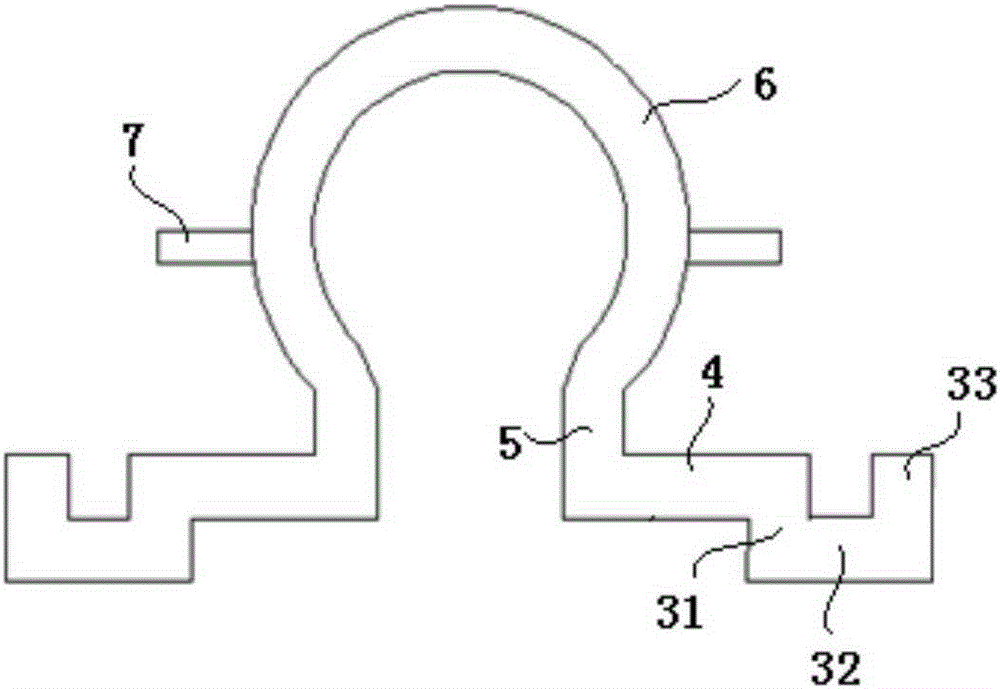

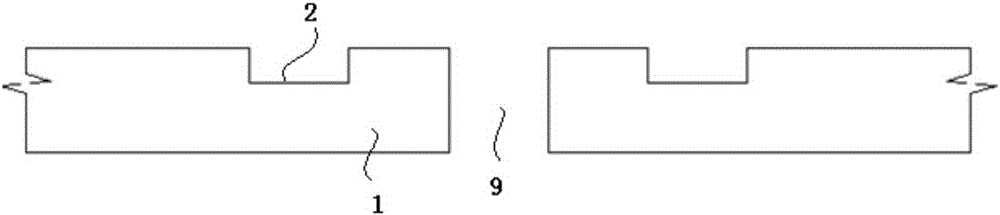

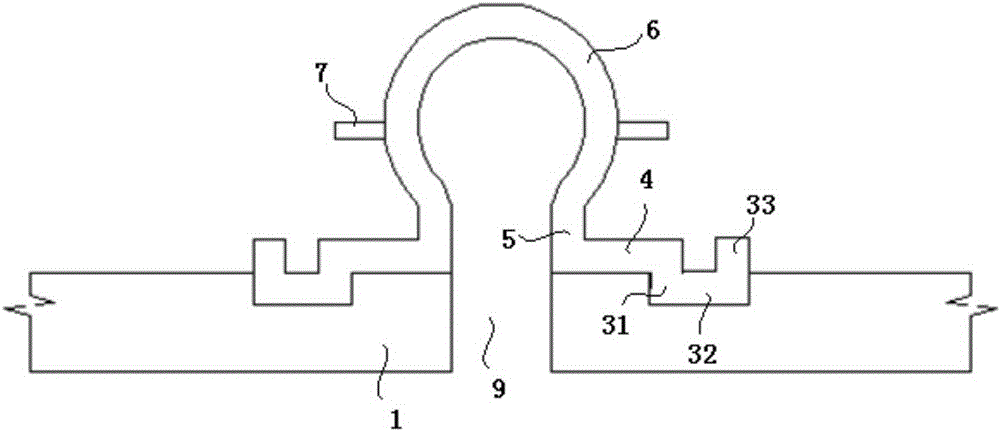

[0051] Such as Figure 4 As shown, a zero-stress seam width self-adaptive waterproofing system for roof reserved seams in this embodiment includes a reserved seam waterproof sealing mechanism, a reserved seam roof embedding groove mechanism and an upper waterproof layer 8; the reserved Seam roof embedding groove mechanism comprises roof subfloor 1, is provided with reserved seam 9 in roof subfloor 1 (as figure 2 As shown), the upper surface of the lower roof layer 1 is provided with embedding grooves 2, the embedding grooves 2 are located on both sides of the reserved seam 9, and the embedding grooves 2 are used to fix the embedding components of the reserved seam waterproof sealing mechanism. The waterproof sealing mechanism of the reserved seam includes an embedded assembly, a horizontal connection section 4, a vertical extension section 5, an elastic ring 6 and ribs 7 (such as figure 1 shown), the material of the reserved seam waterproof sealing mechanism is a low elastic...

Embodiment 2

[0066] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the present invention is a zero-stress seam width adaptive roof seam waterproofing system, and the material of the seam waterproof sealing mechanism is low elastic modulus material, the modulus of elasticity of the low elastic modulus material is 0.1MPa; the cross section of the elastic ring 6 is a ring with one end open, and the outer diameter of the ring is 80mm; the width of the embedding groove 2 is consistent with the total width of the embedding component, Both are 40mm, the depth of the embedding groove 2 is consistent with the thickness of the horizontal section 32, both are 10mm; the side of the embedding groove 2 close to the reserved seam 9 is 20mm from the side edge of the reserved seam 9; the length of the elastic ring 6 Both sides are provided with ribs 7, the ribs 7 are 60 mm away from the bottom of the waterproof sealing mechanism of the reserved seam, and t...

Embodiment 3

[0068] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that the present invention is a zero-stress seam width adaptive roof seam waterproofing system, and the material of the seam waterproof sealing mechanism is low elastic modulus material, the elastic modulus of the low elastic modulus material is 10MPa; the cross section of the elastic ring 6 is a ring with one end open, and the outer diameter of the ring is 120mm; the width of the embedding groove 2 is consistent with the total width of the embedding component, and 50mm, the depth of the embedding groove 2 is consistent with the thickness of the horizontal section 32, which is 15mm; the side of the embedding groove 2 near the reserved seam 9 is 30mm from the side edge length of the reserved seam 9; the two sides of the elastic ring 6 The side is provided with a rib 7, the rib 7 is 100mm away from the bottom of the waterproof sealing mechanism of the reserved seam, and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com