A kind of ultra-thin heat pipe and its manufacturing process

An ultra-thin heat pipe and manufacturing process technology, applied in the field of heat pipes, can solve the problems of affecting the heat dissipation effect of the heat pipe, the length of the invalid end is large, and the space occupied is large, so as to shorten the processing cycle, improve the heat conduction efficiency, and reduce the overall weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

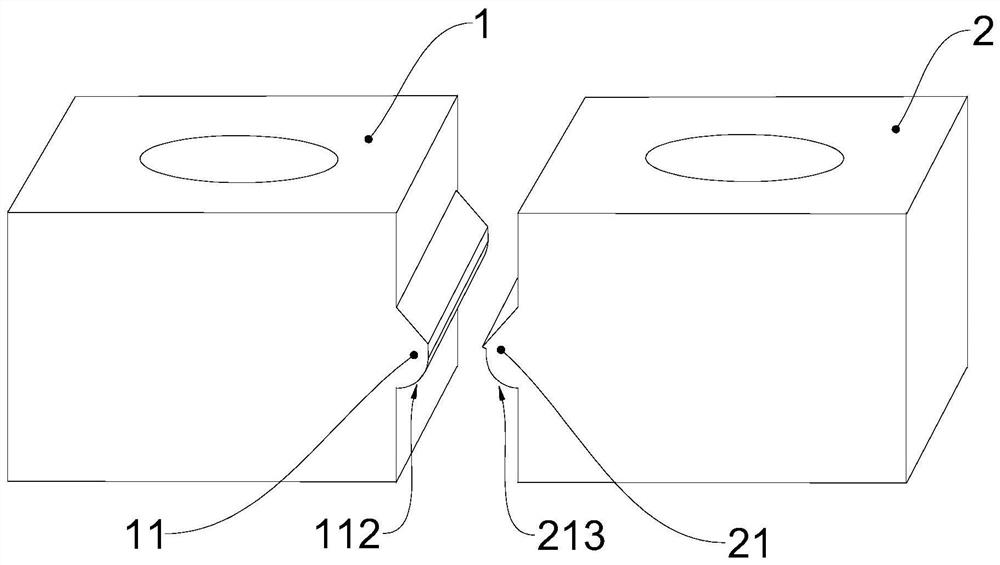

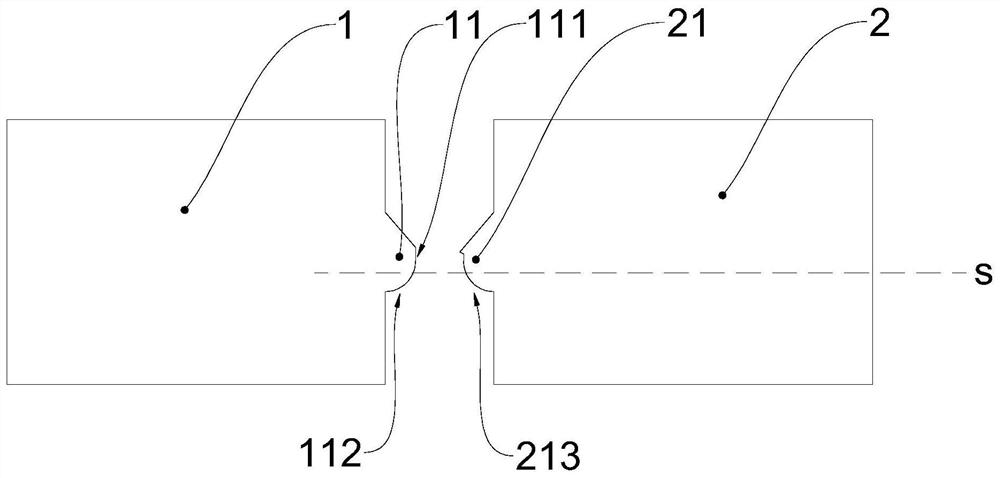

[0046] Such as Figure 2-4 As shown, the sealing and cutting mold includes a left mold 1 and a right mold 2, the side wall of the left mold 1 is provided with a sealing and cutting part 11, and the sealing and cutting part 11 has a sealing and cutting surface perpendicular to the horizontal plane s One 111, the side wall of the right mold 2 is provided with a sealing and cutting part two 21, the sealing and cutting part two 21 has a sealing and cutting surface two 211 and a cutter 212 perpendicular to the horizontal plane s, when sealing and cutting the heat pipe, The right mold 2 is close to the left mold 1, and the heat pipe is sealed by the pressing effect of the first sealing cutting surface 111 and the second sealing cutting surface 211, and the excess part is cut off by the cooperation between the cutter 212 and the first sealing cutting surface 111 .

Embodiment 2

[0048] Such as Figure 4 As shown, the vertical distance between the end of the sealing cutting surface 2 211 away from the cutter and the cutting edge of the cutter 212 is 1-5mm, so that the sealing width of the heat pipe (that is, the length of the dead end) is 1-5mm, and the heat pipe port is tightly sealed. At the same time, minimizing the length of the ineffective end is beneficial to improving the heat conduction efficiency of the heat pipe, reducing the volume of the heat pipe, saving the layout space of the heat pipe in the electronic product, and helping to reduce the overall weight of the electronic product.

Embodiment 3

[0050] Such as Figure 4 As shown, the cutter 212 is in contact with the top of the sealing cutting surface 211, and the bottom of the sealing cutting surface 1 111 and the bottom of the sealing cutting surface 2 211 are located on the same horizontal plane, which is conducive to neatly sealing the heat pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com