Mounting method for thermal power plant wet chimney with flame retardant anti-corrosion glass fiber reinforced plastic structure

An installation method and fiberglass technology, applied in the direction of building types, buildings, towers, etc., can solve the problems of connection structure, hoisting and installation without mature technical reports, etc., achieve overall and local stability, safety and reliability, excellent chemical corrosion resistance, design technology mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

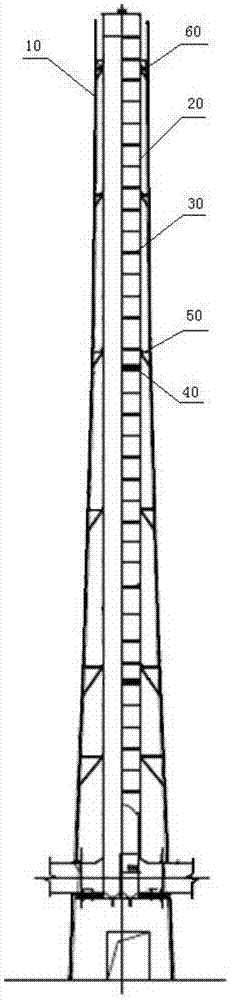

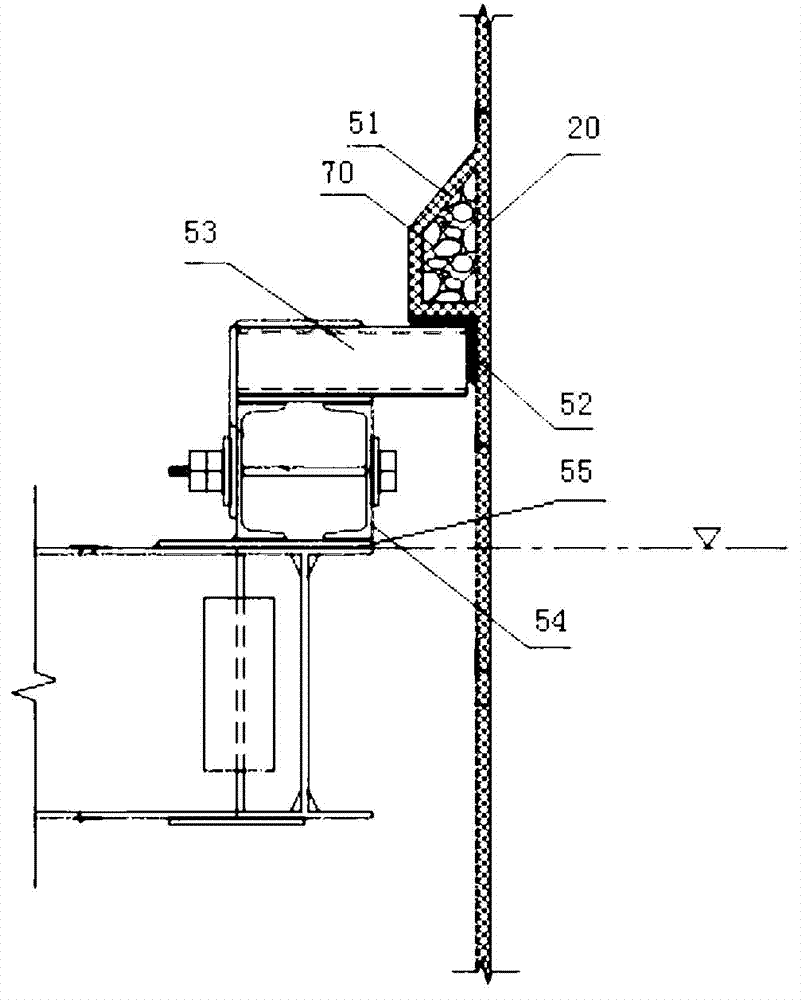

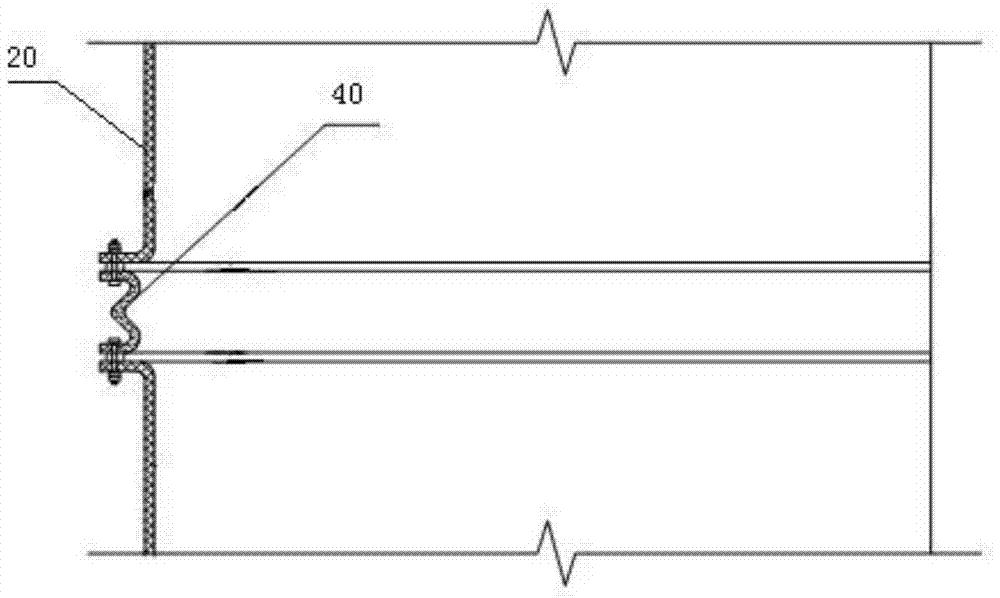

[0035] The components in the drawings are numbered as follows: outer support mechanism 10, fiberglass lining 20, reinforcing rib 30, non-metallic expansion joint 40, support node 50, lining corbel 51, steel ring beam 52, prefabricated corbel 53, ring beam Support 54, load-bearing platform 55, anti-sway point 60, anti-sway platform 61, anti-sway bracket 62, cantilever connector 63, suspension anti-sway cantilever 64, anti-sway arm support 65, hard polyurethane material 70.

[0036] The present invention relates to a method for installing a fire-resistant and anti-corrosion glass-steel structure wet chimney for a thermal power plant. The wet chimney is composed of an outer support mechanism 10 and a fiberglass inner lining 20. The outer support mechanism 10 is a reinforced concrete outer cylinder or a steel structure support frame, and the glass fiber reinforced plastic The lining 20 is an integral inner cylinder made of multi-section glass fiber reinforced plastic cylinders made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com