Molded surface connection device between supports

A technology for connecting devices and connecting parts, which is applied to the connection of rods, connecting components, mechanical equipment, etc. It can solve the problems of uneven brackets, unsightly appearance, and low efficiency, and achieve reliable quality, simple and compact structure, and convenient production and installation. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the patent of the present invention is described further.

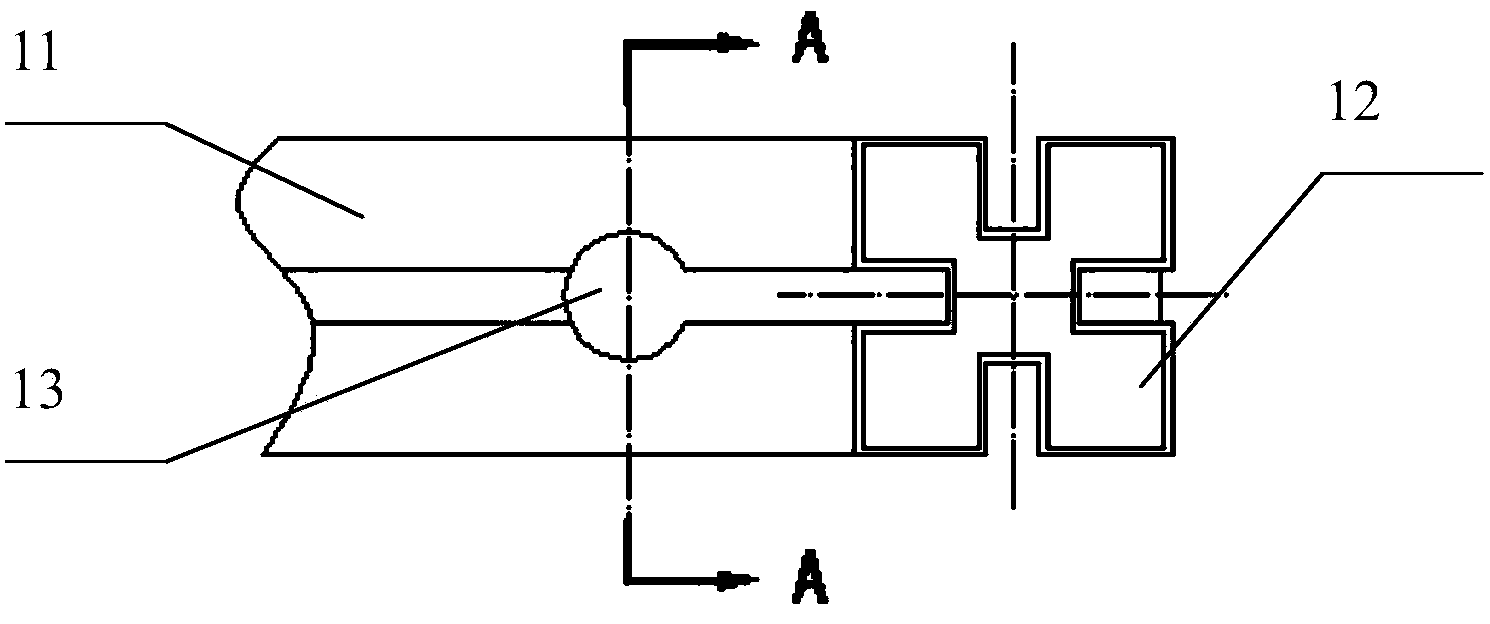

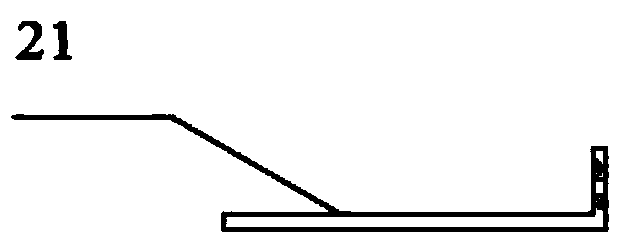

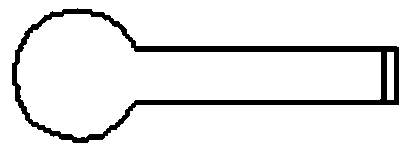

[0017] Referring to the accompanying drawings, a new profile connecting device between brackets includes a bracket 11, a bracket 2 12, a profile connector 13, a tightening assembly 1 81-1, a tightening assembly 2 81-2, and a profile Connector two 82, profile connector 21, bracket three 41, profile connector three 42, bracket four 43, profile connector five 44, bracket five 45, bracket six 51, profile connector seven 52, bracket seven 53, profile connector 9 54, bracket 8 55, profile connector 11 61, bracket 9 62, bracket 10 63, profile connector 13 64, bracket 11 65, bracket 12 66, profile connection Part 15 67, bracket 13 71, profile connector 17 72, bracket 14 73, profile connector 19 74, bracket 15 75, profile connector 21 76, bracket 16 77, Support seventeen 78, surface connector twenty-three 79. Among them, bracket one 11, bracket four 43, bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com