A Method for Improving the Stability of Clutch Output Torque During Automobile Starting

A technology for output torque and car starting, applied in the automotive field, can solve the problems of reducing the compression force of the diaphragm spring, reducing the life of the face sheet, increasing the sliding time, etc., and achieving the effect of reducing volatility, small fluctuations, and smooth transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

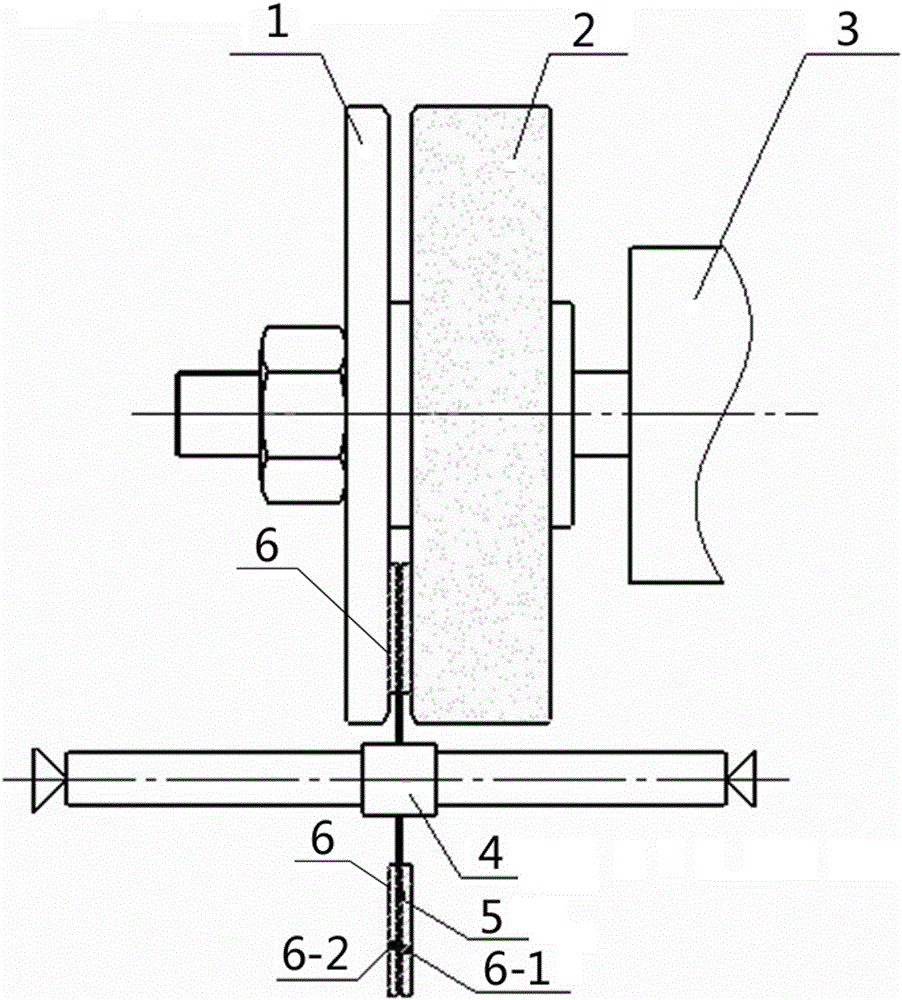

[0013] refer to figure 1 , a method for improving clutch output torque stability in the process of starting a car, comprising the steps of:

[0014] (1) Measure the free thickness of the friction plate 6 of the driven disc. For example, the free thickness requirement of a Φ200 driven plate is 8.3±0.3mm; the pressing thickness requirement is 7.7±0.3mm; adjust the distance between the grinding plate 1 and the grinding wheel 2 to 8mm;

[0015] (2) Install the driven disc assembly 4 on the mandrel, and fix the mandrel on the top of the grinding machine; adjust so that the A side 6-1 of the friction plate is fully in contact with the 2 sides of the grinding wheel;

[0016] (3) Set the grinding parameters of the grinding machine, and the power base 3 drives the grinding wheel 2 to grind at 1000 rpm;

[0017] (4) The friction plate 6 of the driven disk is between the pressure plate 1 and the grinding wheel 2, and it is ground by the elastic force of the corrugated plate 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com