Epicyclic gear train type inertia variable flywheel

A technology of epicyclic gear train and variable inertia, applied in the field of flywheel, can solve the problem that the flywheel cannot meet the requirements of rapid change of moment of inertia, and achieve the effect of reducing friction and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

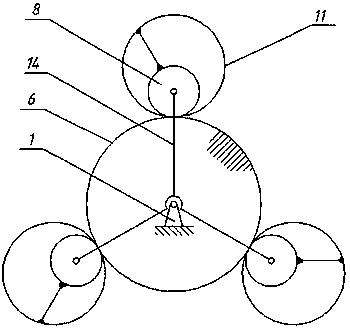

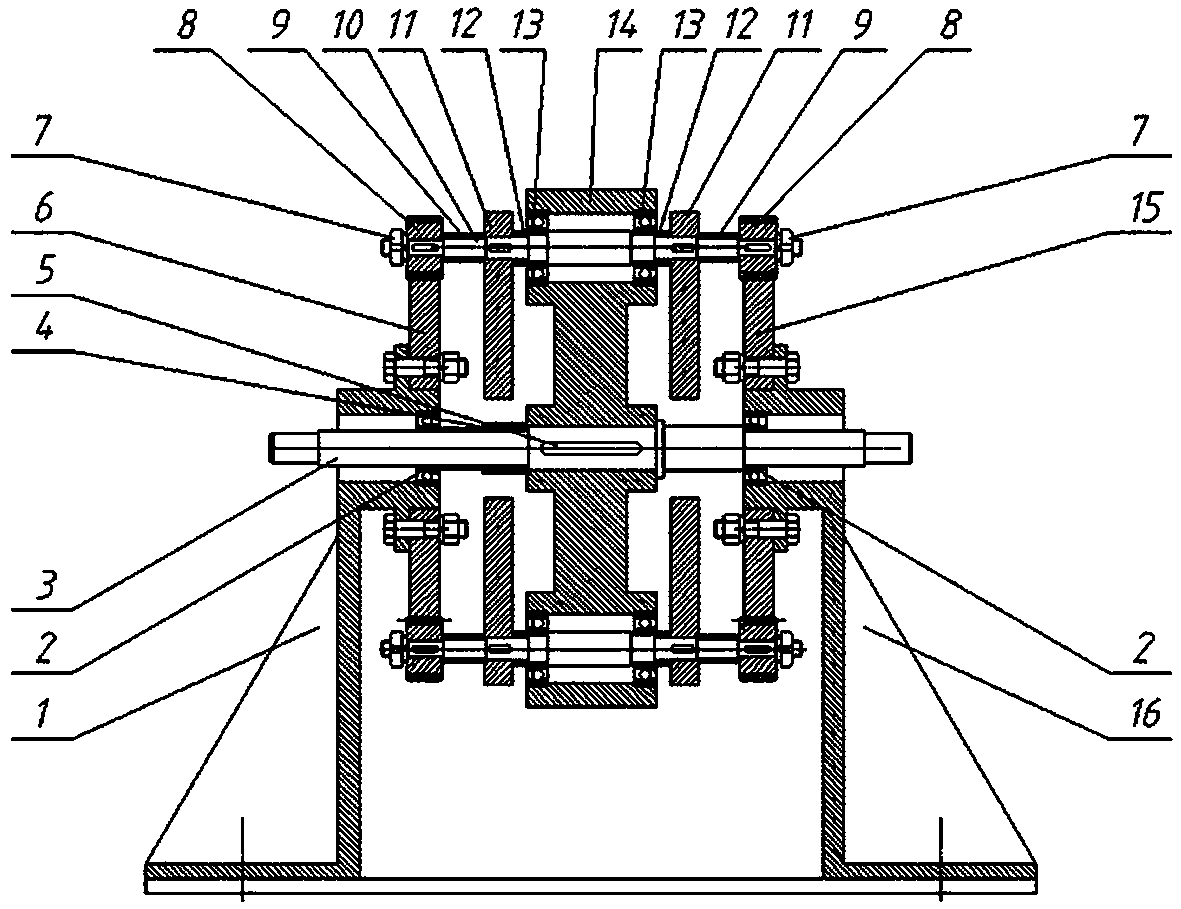

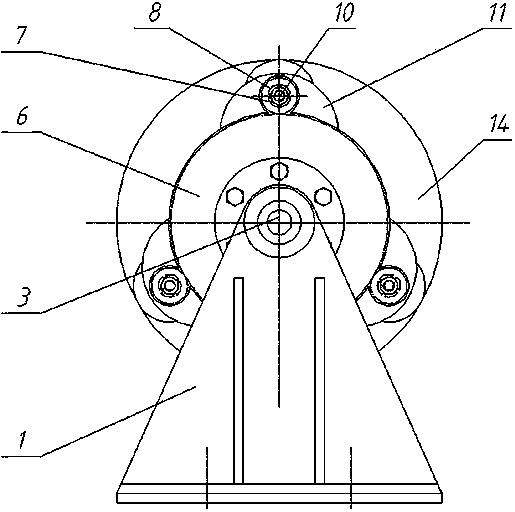

[0020] Refer to attached Figure 1~4 , The epicyclic gear train type variable inertia flywheel includes a frame assembly, a main flywheel assembly and 3 sets of eccentric turntable assemblies. Described frame assembly comprises frame one 1, frame two 16, bull gear one 6 and bull gear two 15, is respectively provided with flywheel spindle installation hole on frame one 1 and frame two 16, and bull gear one 6 Be fixed on the frame one 1, and the gear wheel two 15 is fixed on the frame two 16. The main flywheel assembly includes a flywheel 14, a flywheel main shaft 3, an axle sleeve 4, a flat key 5, and a bearing 2. The center of the flywheel is provided with a flywheel spindle installation hole, and the eccentric turntable spindle installation holes are distributed in thirds on the rim of the flywheel. The flywheel spindle 3 is fixedly installed in the flywheel spindle installation hole through the flat key 5, and the two ends of the flywheel spindle are respectively installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com