Outdoor unit of air conditioner

A technology for air conditioners and outdoor units, which is applied in the field of outdoor units and can solve problems such as heat exchanger deformation, melting, and refrigerant pipe cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

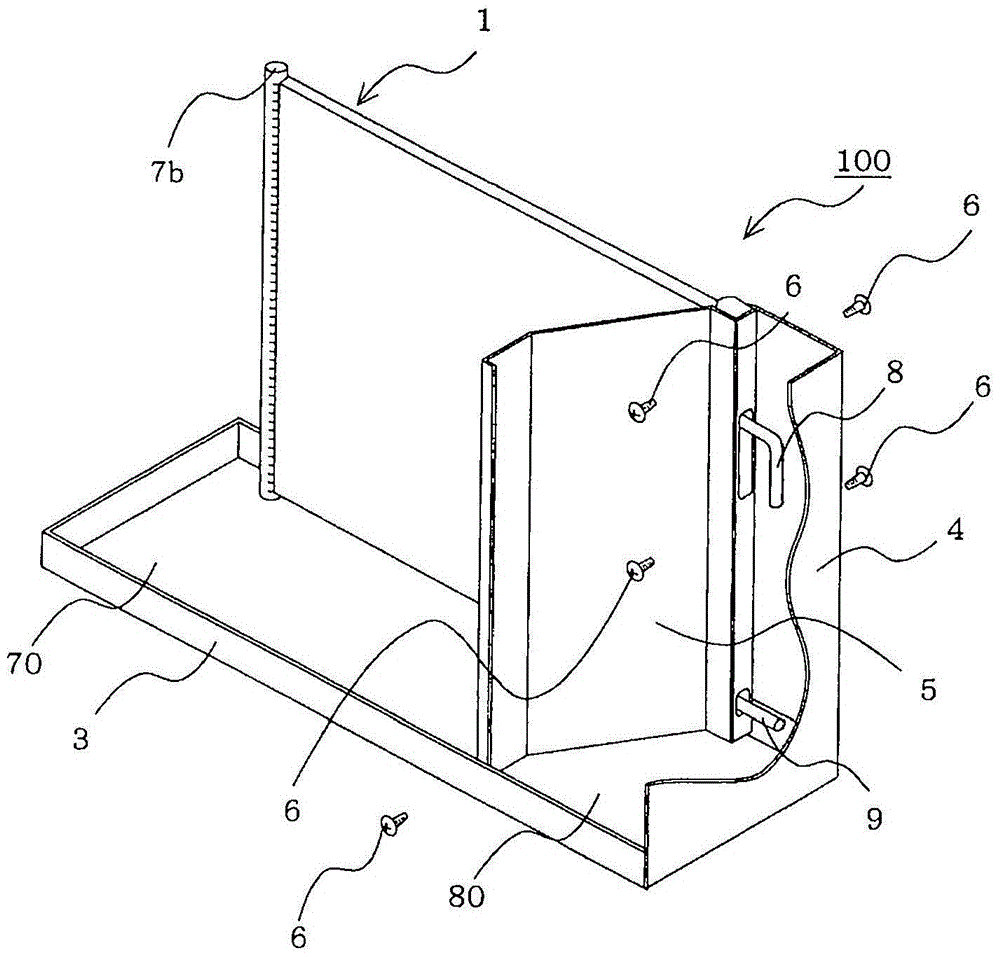

[0033] figure 1 It is a perspective view of the outdoor unit 100 of the air conditioner which concerns on 1st Embodiment of this invention.

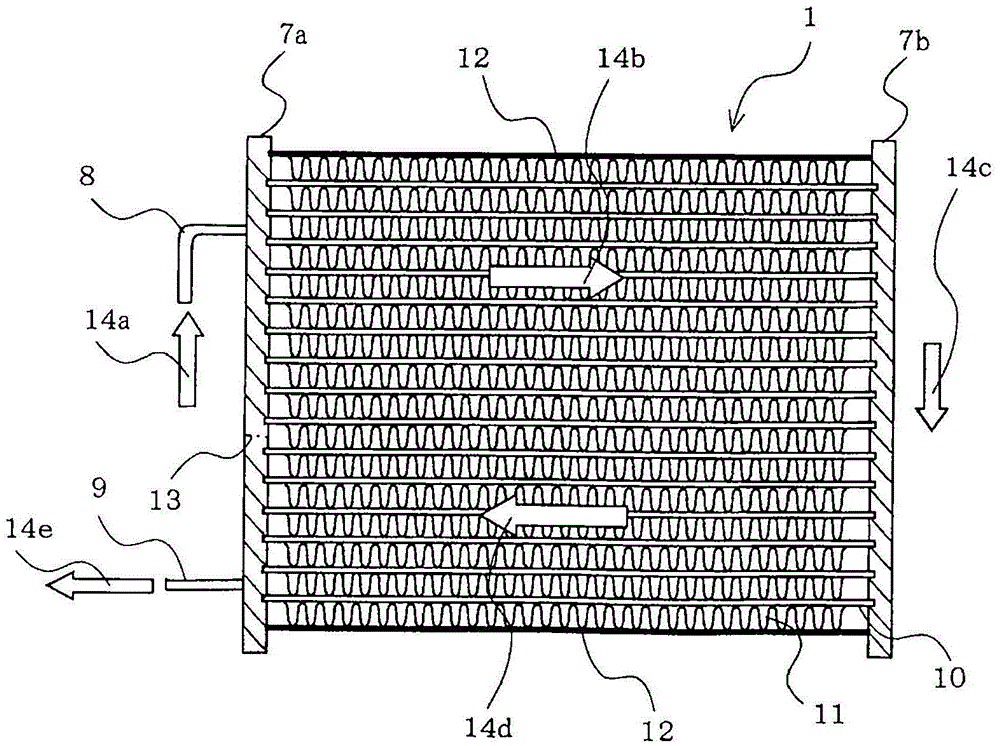

[0034] figure 2 It is a front view of the heat exchanger 1 mounted on the outdoor unit 100 .

[0035] based on figure 1 with figure 2 The structure and function of the outdoor unit 100 will be described.

[0036] Such as figure 1 As shown, the outdoor unit 100 includes a heat exchanger 1 , a base plate 3 , a rear plate 4 , a partition plate 5 , and screws 6 .

[0037] The heat exchanger 1 is formed of, for example, an aluminum parallel pipe heat exchanger, and is provided on the rear side of the outdoor unit 100 . The heat exchanger 1 will be specifically described later. The base plate 3 has a box shape with an open top and constitutes the bottom of the outdoor unit 100 . Components such as the heat exchanger 1 accommodated in the outdoor unit 100 are placed on the base plate 3 . The rear panel 4 is a panel constituting a ...

no. 2 approach

[0085] Figure 9 It is a partial perspective view of the outdoor unit 100 of the air conditioner which concerns on 2nd Embodiment of this invention.

[0086] Such as Figure 9 As shown, a screw hole 3 a is formed in the standing portion on the front side of the substrate 3 , and a screw hole 5 a is formed in the lower portion on the front side of the partition plate 5 . Therefore, the substrate 3 and the partition plate 5 can be fixed by sequentially inserting the screws 6 through the screw holes 3 a and 5 a in a state where the back surface of the upright portion on the front side of the substrate 3 is in contact with the lower portion on the front side of the partition plate 5 . .

[0087] In addition, screw holes 5 c and 5 d are formed on the back surface of the partition plate 5 , and screw holes 17 c and 17 d are formed on the front surface of the fixture 17 . Therefore, in a state where the back surface of the substrate 3 is in contact with the front surface of the pa...

no. 3 approach

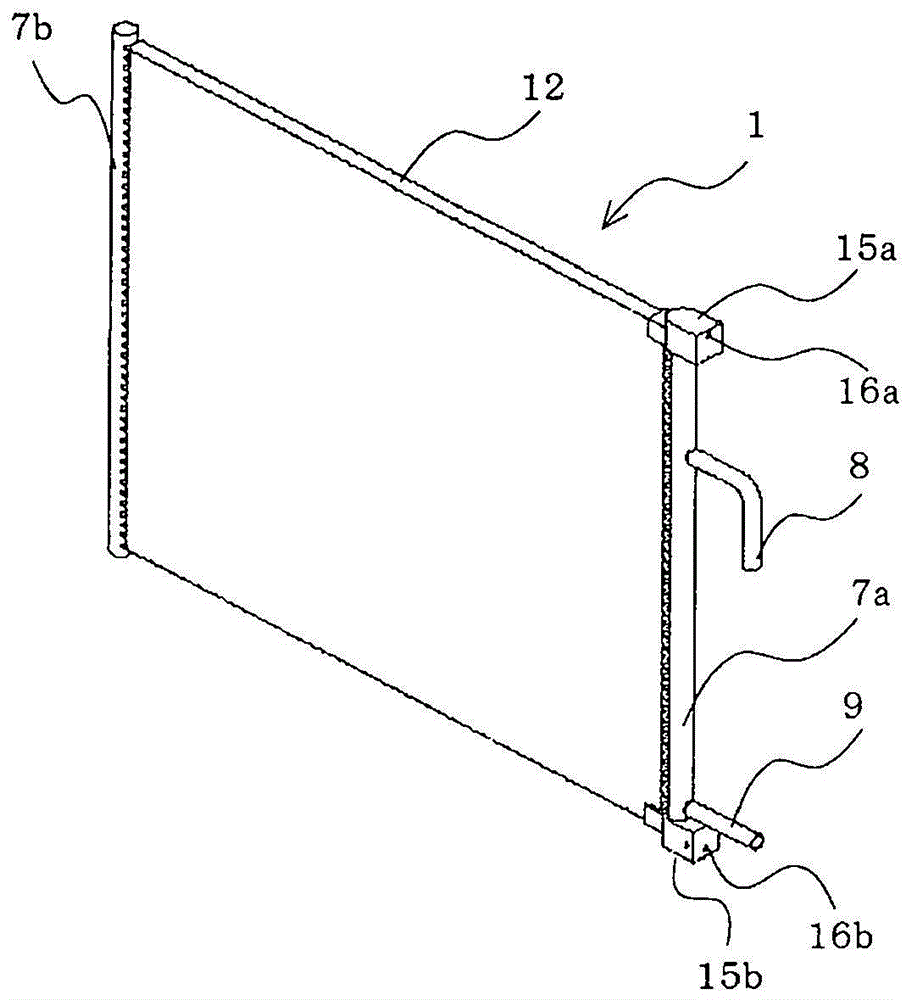

[0090] Figure 10 It is a perspective view of the heat exchanger 1 attached to the outdoor unit 100 mounted on the air conditioner according to the third embodiment of the present invention.

[0091] Such as Figure 10 As shown, the second spacer 23a is attached to the upper surface of the side plate 12a, and the second spacer 23b is attached to the lower surface of the side plate 12b, and each spacer is made of, for example, a U-shaped resin member. The second spacer 23a, 23b is located between the two manifolds 7 . In addition, "コ-shape" means a shape that forms the shape of the katakana character "コ".

[0092] In addition, the side plates 12a and 12b may be collectively referred to as "side plates 12". In addition, the second spacers 23a and 23b may be collectively referred to as "second spacers 23".

[0093] Figure 11 It is a perspective view of the second spacer 23 attached to the heat exchanger 1 mounted on the outdoor unit 100 .

[0094] Figure 12 It is a plan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com