Grease composition, rolling bearing and variable frequency motor

A grease composition and a frequency conversion motor technology, applied in the field of grease compositions, can solve the problems of not considering electrical corrosion resistance and low torque characteristics, and achieve the effect of inhibiting electric corrosion and excellent low torque characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1~9

[0094] According to the formulation shown in Table 1 and Table 2, a test grease composition was prepared using base oil, thickener, and additives as raw materials. The evaluations described above were performed on the obtained test grease composition. In addition, in Comparative Example 9, Multemp SRL (dynamic viscosity (40° C.): 25 mm 2 / s) and evaluated. The results are shown in Table 1 and Table 2.

[0095] [Table 1]

[0096] [Table 1]

[0097] Table 1

[0098]

[0099] [Table 2]

[0100] [Table 2]

[0101] Table 2

[0102]

[0103] Symbol Description

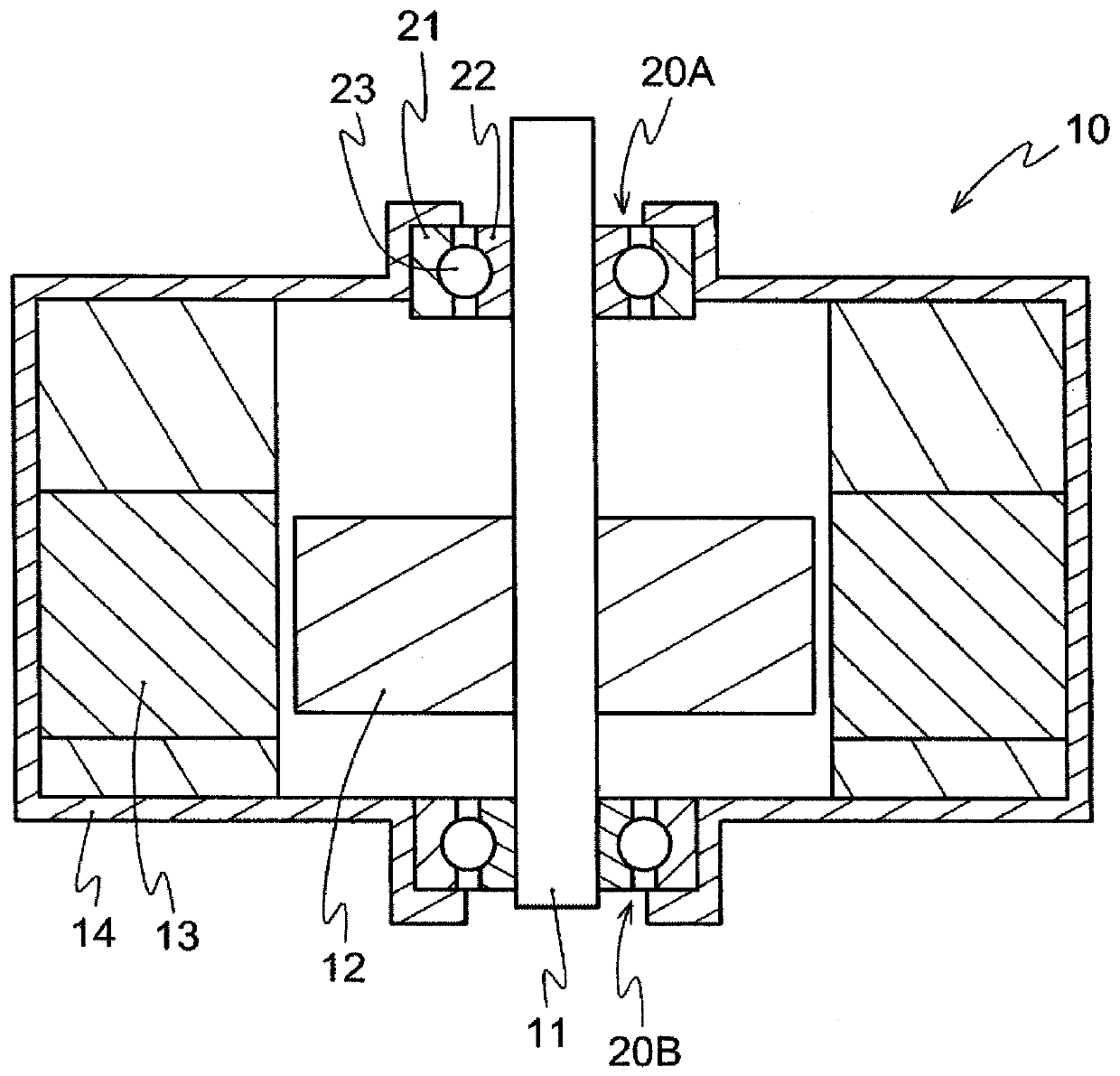

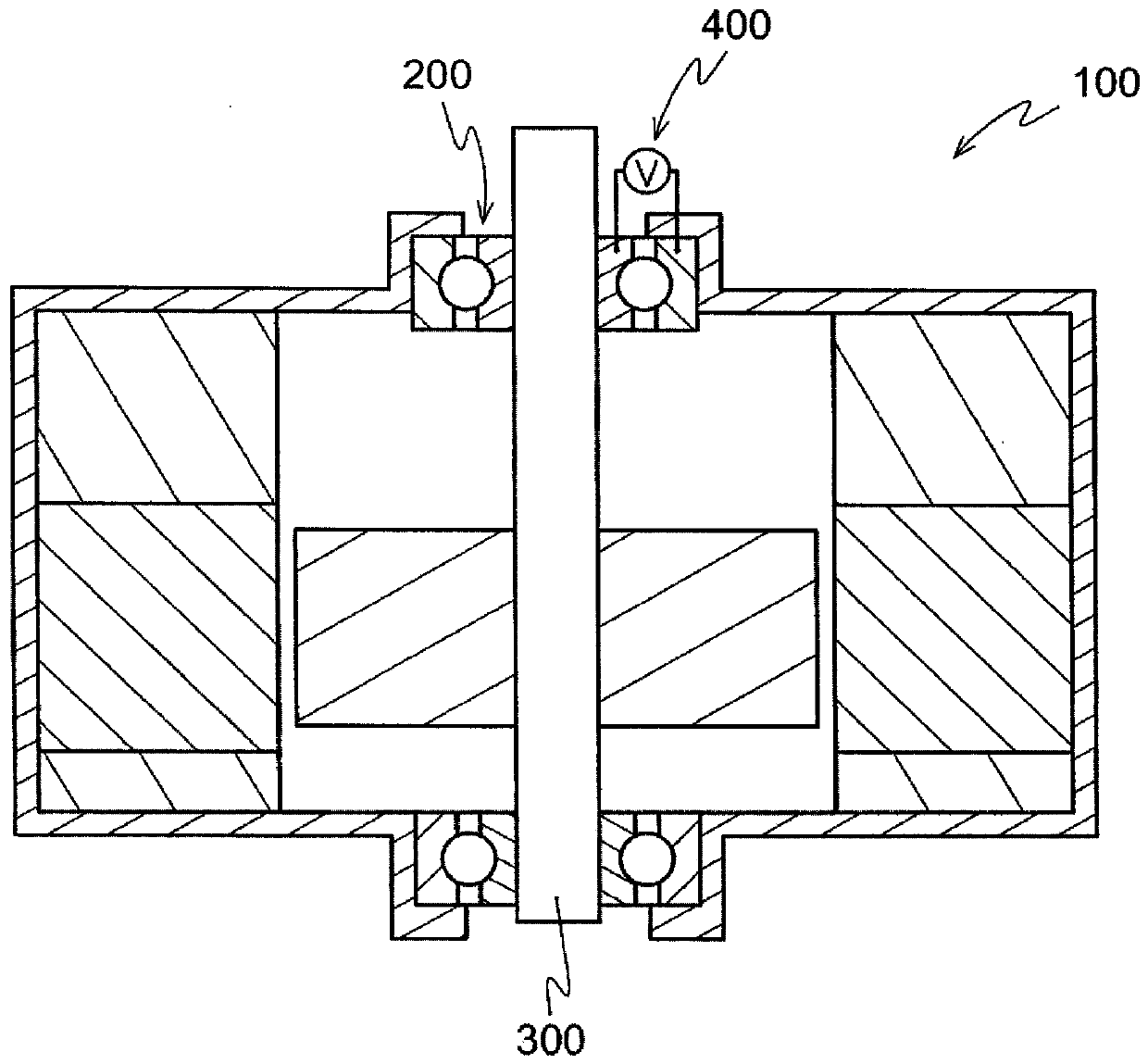

[0104] 10 variable frequency motor

[0105] 11 axis of rotation

[0106] 12 rotors

[0107] 13 Stator

[0108] 14 Chassis

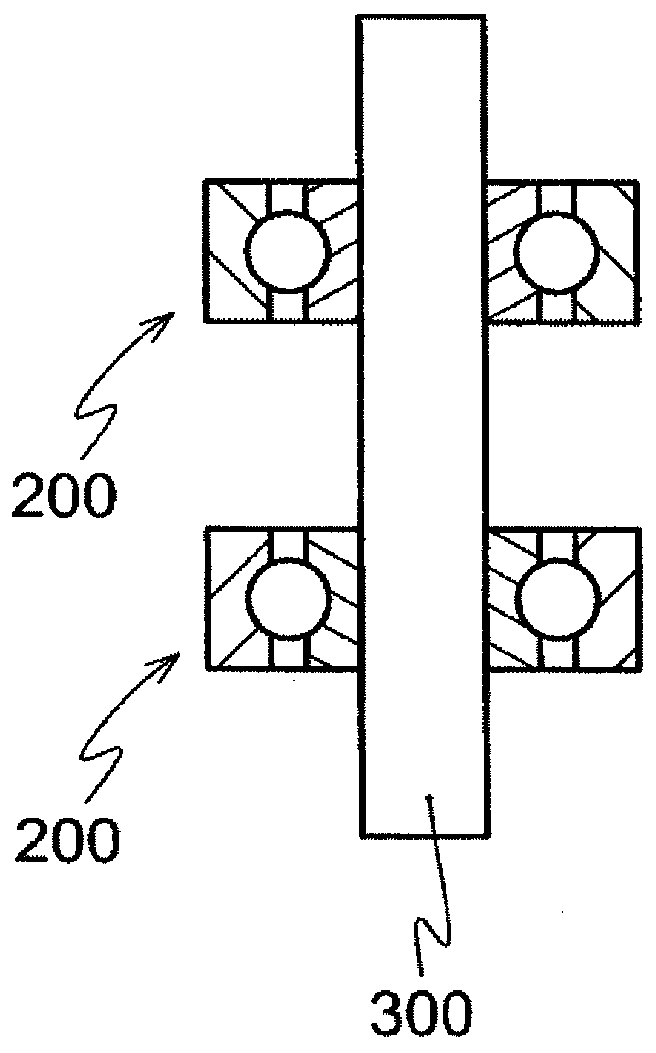

[0109] 20A rolling bearing

[0110] 20B Rotary bearing

[0111] 21 outer ring

[0112] 22 inner ring

[0113] 23 rotating body

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com