Metal-fiber reinforced resin material composite body and method for producing metal-fiber reinforced resin material composite body

A technology of resin materials and composites, applied in chemical instruments and methods, metal layered products, synthetic resin layered products, etc., can solve the problems of long curing time, high cost, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

[0116] [Structure of metal-fiber reinforced resin material composite]

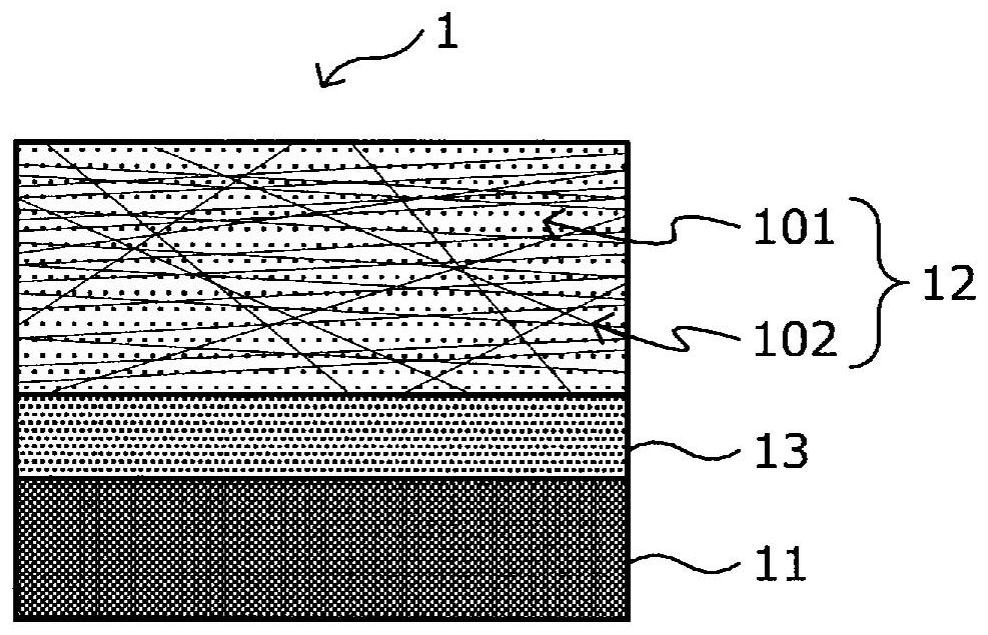

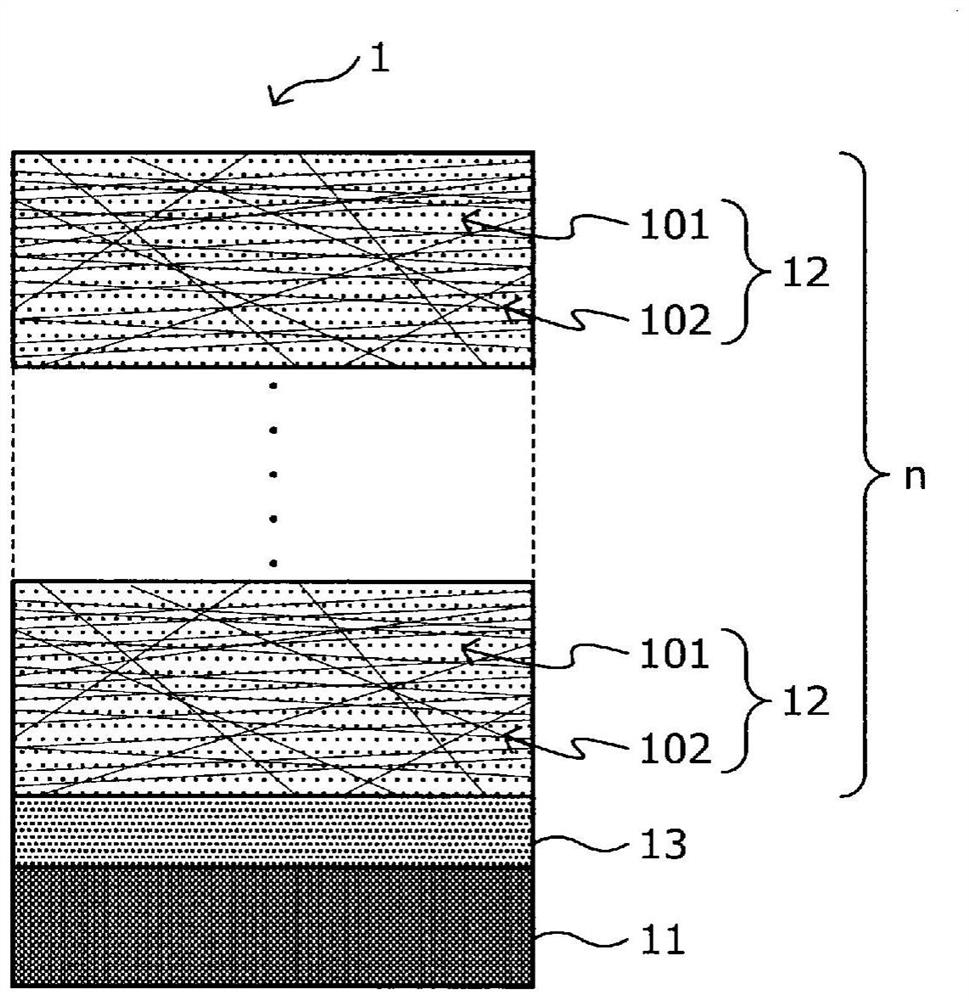

[0117] First, refer to figure 1 with figure 2 The configuration of the metal-fiber reinforced resin material composite according to the first embodiment of the present invention will be described. figure 1 with figure 2 It is a schematic diagram showing the cross-sectional structure in the lamination direction of the metal-FRP composite 1 as an example of the metal-fiber-reinforced resin material composite according to the present embodiment.

[0118] Such as figure 1 As shown, the metal-FRP composite 1 includes a metal member 11, an FRP layer 12 as an example of the first fiber-reinforced resin material according to this embodiment, and an adhesive resin layer 13. The metal member 11 and the FRP layer 12 are composited via the adhesive resin layer 13. Here, "combination" means that the metal member 11 and the FRP layer 12 (first fiber-reinforced resin material) are joined (laminated) via the adhesive resin l...

Embodiment 15

[0326] In Example 15, a hot-dip galvanized high-strength steel sheet made by Nippon Steel & Sumikin Co., Ltd., with a thickness of 0.42 mm, was used as the metal member, and this was sufficiently degreased with acetone. Next, in order to quantitatively adhere the oil component to the surface of the metal member, the rust preventive oil ダフニーオイルコート Z3 manufactured by Idemitsu Co., Ltd. was added at a rate of 5 g / m 2 Apply the amount of oil, then gently press the oil-absorbing cloth to absorb just the low amount of oil, and then use. On the metal member, the oil-surface adhesive adhesive Alphatec 370 made by Alpha Industry Co., Ltd. was used at 3g / m 2 The amount of coating. Except for the above-mentioned points, the same procedure as in Example 13 was carried out to produce a sample of a metal-CFRP composite.

Embodiment 16

[0327] In Example 16, a hot-dip galvanized high-strength steel sheet manufactured by Nippon Steel & Sumitomo Metal Co., Ltd. with a thickness of 0.42 mm was used as the metal member, and this was sufficiently degreased with acetone. Next, in order to quantitatively adhere the oil component on the surface of the metal member, the rust preventive oil ダフニーオイルコート Z3 manufactured by Idemitsu Co., Ltd. was added at a rate of 5 g / m 2 The amount is applied and then used. Prepare a mixture of finely pulverized Mitsui Chemicals Admate QE06050 parts by mass, and Alfumec 370 manufactured by Alpha Industry Co., Ltd. as an oil-face adhesive adhesive, and a mixture of 50 parts by mass mixed in a mass ratio of 100:30 Parts by mass, the mixture is further mixed with Mitsui Chemicals’ Adma QE060 at 4g / m 2 The amount is coated on the metal member. Except for the above-mentioned points, a sample of a metal-CFRP composite was produced in the same manner as in Example 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com