Motors and electrical equipment equipped with such motors

A technology of electric motors and electrostatic capacitors, applied in the field of electric motors, can solve problems such as high shaft voltage and electric corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

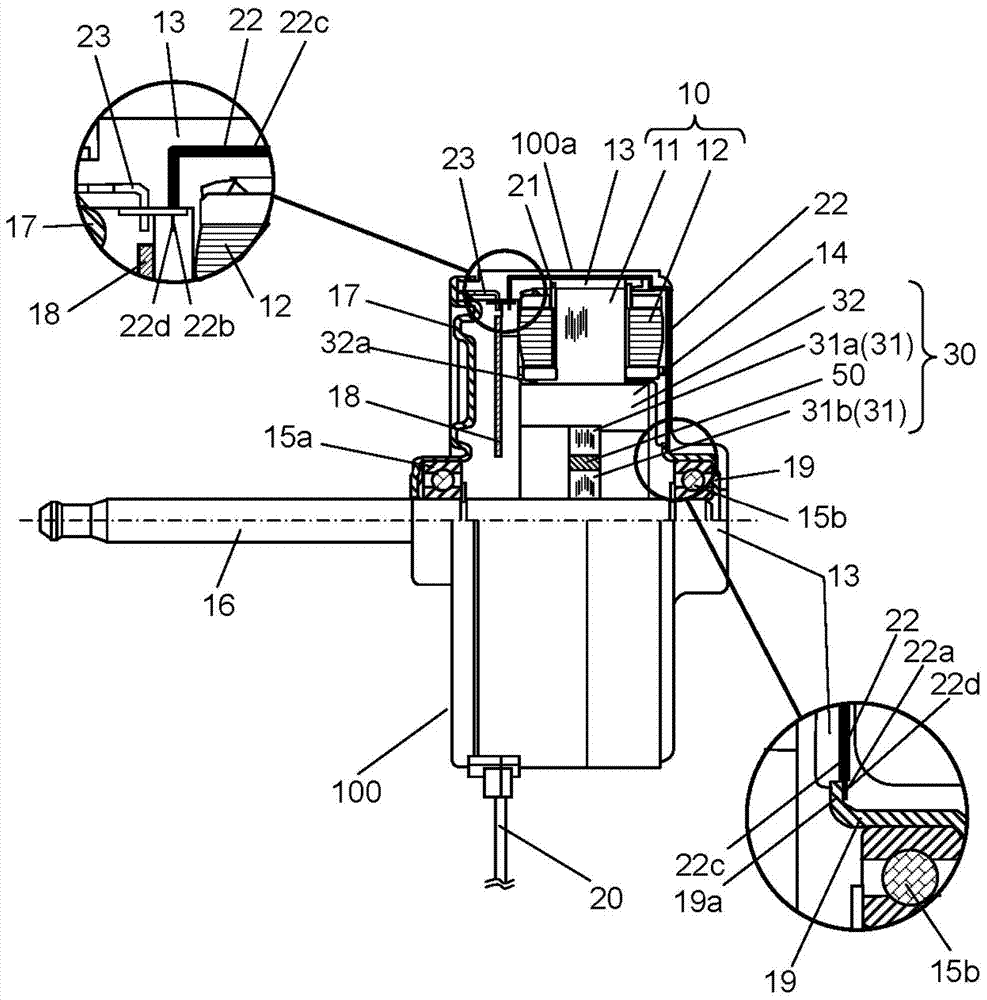

[0047] figure 1 It is a configuration diagram showing a cross section of the motor according to Embodiment 1 of the present invention and an enlarged main part. figure 2 It is a perspective structural view of the rotating body used for the electric motor of this Embodiment 1.

[0048] In this embodiment, a motor mounted in an air conditioner as an electric device will be described as an example. This motor is a brushless motor that drives a blower fan. This motor is an inner rotor type motor. In the inner rotor type motor, the rotor is rotatably arranged on the inner peripheral side of the stator.

[0049] Such as figure 1 As shown, the brushless motor 100 as the electric motor according to Embodiment 1 of the present invention includes a stator 10, a rotor 14, a pair of bearings 15a, 15b, a pair of brackets 17, 19, and a lead wire 22 as a conductive material.

[0050] The stator 10 has a stator winding 12 as a winding and a stator core 11 around which the stator winding 1...

Embodiment 1

[0097] In Embodiment 1 of the present invention, Example 1, which is a specific example thereof, will be described with reference to the drawings.

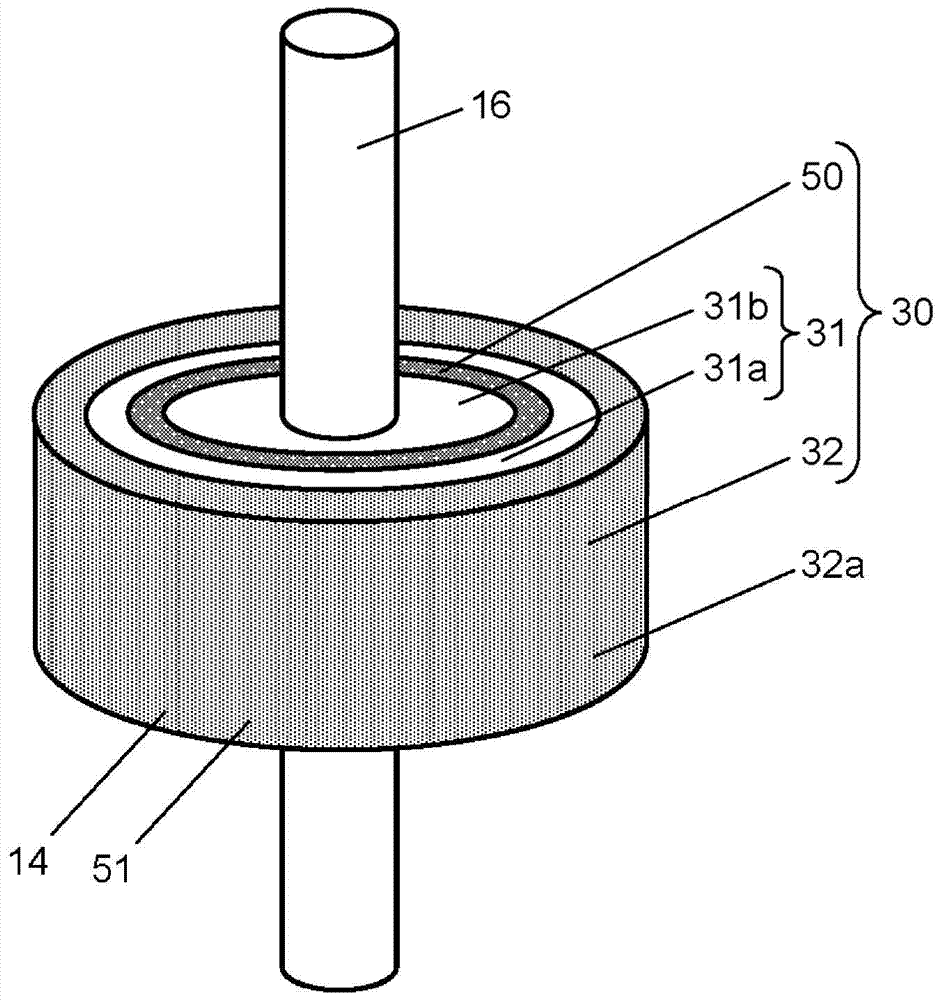

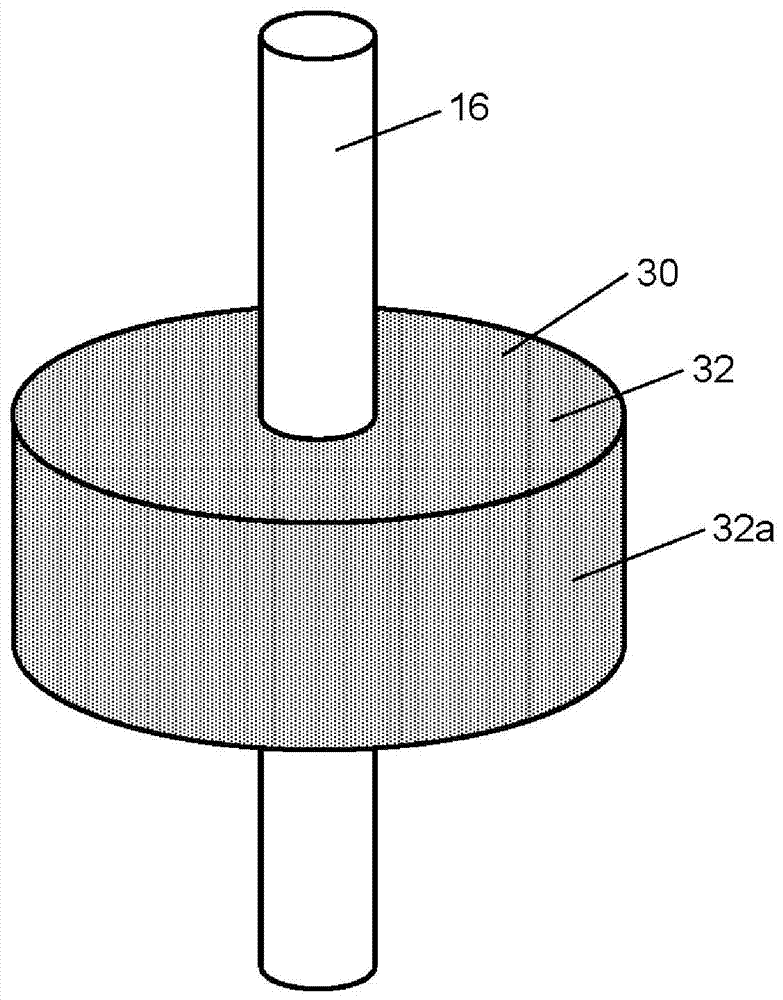

[0098] figure 2 It is a perspective structural view of the rotating body used for the electric motor of this Embodiment 1. Such as figure 2 As shown, the rotating body 30 is provided with a dielectric layer 50 between the rotating shaft 16 and an outer peripheral portion 51 having an outermost peripheral surface 32 a serving as an outer periphery of the rotating body 30 parallel to the axial direction of the rotating body 30 .

[0099] The rotating body 30 of the first embodiment fixes the rotor core 31 around the rotating shaft 16 along the axial center direction of the rotating shaft 16 . The rotating shaft 16 passes through the axis of the rotor core 31 , so the axis of the rotating shaft 16 is the same as that of the rotating body 30 . On the outer periphery of the rotor core 31 there is an outer peripheral portion 51 par...

Embodiment approach 2

[0166] An electric device using the electric motor described in Embodiment 1 of the present invention will be described with reference to specific examples.

[0167] First, as Embodiment 2 of the present invention, a case where the electric motor is used in an indoor unit of an air conditioner will be described.

[0168] Such as Figure 15 As shown, an indoor unit 210 of an air conditioner includes a motor 201 inside a casing 211 . A cross flow fan (cross flow fan) 212 is attached as a load to the motor 201 on the output shaft side of the rotating shaft. The indoor unit 210 of the air conditioner includes a motor drive device 213 as a drive unit for driving the motor 201 inside a casing 211 . The motor 201 is driven by a motor drive device 213 . The motor 201 rotates according to a drive signal from the motor drive device 213 . If the motor 201 rotates, the cross flow fan 212 also rotates. The cross-flow fan 212 is rotated, and the air conditioned by the heat exchanger fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com