Novel air source heat pump heat exchange system

A technology of air source heat pump and heat exchange system, which is applied in the direction of lighting and heating equipment, evaporator/condenser, fluid circulation arrangement, etc., to achieve the effect of long service life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

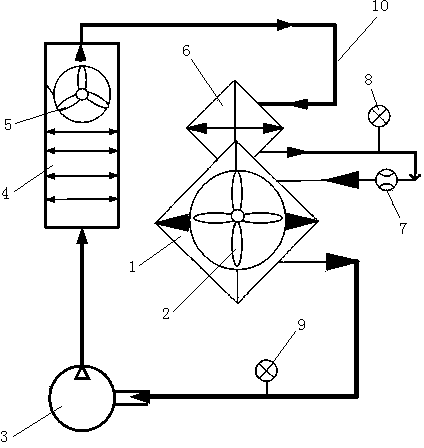

[0013] Embodiment one: if figure 1 As shown, a new type of air source heat pump heat exchange system includes a heat pump unit, the heat pump unit includes an evaporator assembly, a compressor 3, a condenser assembly and a throttling device 7, and the evaporator assembly includes an evaporator 1, an installation Heat exchange fan 2 on the evaporator, a second condenser 6 covered on the evaporator 1, the condenser assembly includes a condenser 4 and a fan 5 arranged on the condenser, the evaporator 1, compressor 3 , the condenser 4 , the second condenser 6 and the throttling device 7 are sequentially connected end to end through a pipeline 10 to form a circulation loop, and a refrigerant circulates in the pipeline 10 .

[0014] In this embodiment, a high pressure gauge 8 is provided on the pipeline 10 between the second condenser 6 and the throttling device 7, and the high pressure gauge 8 monitors the pressure of the refrigerant in the pipeline. When the pipeline pressure exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com