A Comprehensive Measuring Device for Static and Dynamic Stiffness of Ball Screw

A ball screw and comprehensive measurement technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of not having a measuring device, etc., and achieve the effect of improving sensitivity, small motion friction, and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

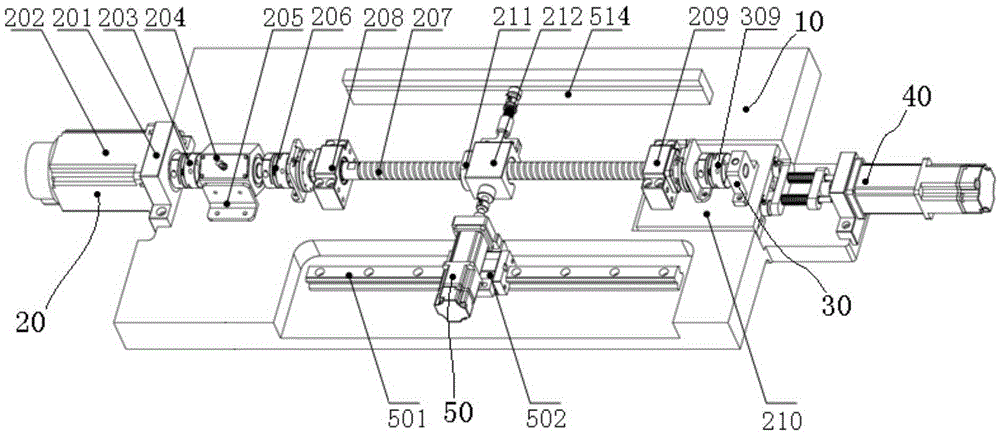

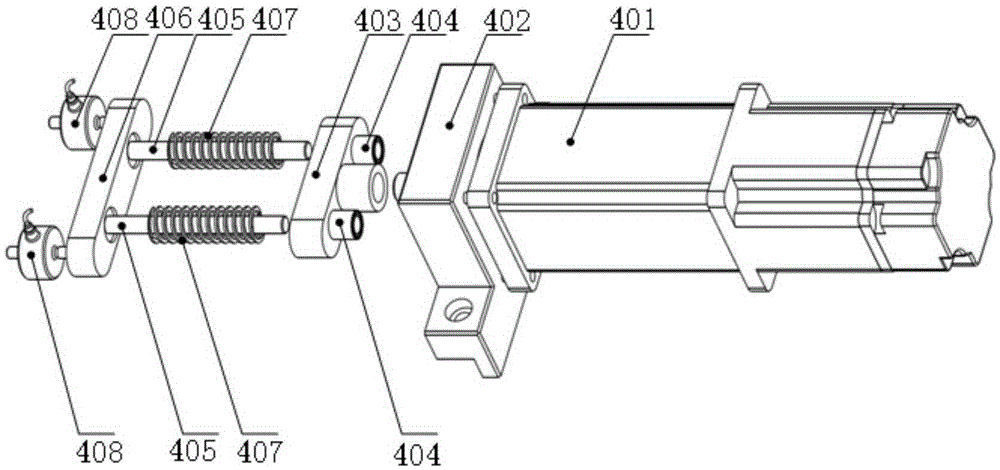

[0022] like figure 1 As shown, the present invention includes a bottom plate 10 , a linear feed mechanism 20 , a torque static and dynamic stiffness measurement mechanism 30 , an axial static and dynamic stiffness measurement mechanism 40 and a transverse static and dynamic stiffness measurement mechanism 50 .

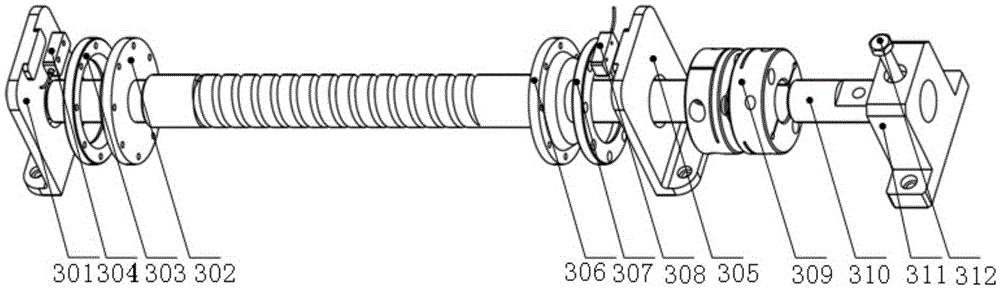

[0023] The linear feed mechanism 20 includes a servo motor 202 fixed on the base plate 10 through a motor support 201, the rotating shaft of the servo motor 202 is connected to one end of a torque sensor 204 through a coupling 203, and the torque sensor 204 passes through a sensor bracket 205 Fixed on the base plate 10, the other end of the torque sensor 204 is connected to one end of a ball screw 207 through a coupling 206, and the ball screw 207 is rotatably supported on two fixed support seats 208, 209, and the two fixed support seats 208, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com