Touch display panel and forming method thereof and touch displayer and forming method thereof

A technology of touch display panel and touch layer, which is applied in the field of touch display panel and its formation, touch display and its formation, and can solve the problem that touch layer lamination is easily disturbed or damaged, consumes materials and manpower, and displays Brightness reduction and other issues can be achieved to enhance touch sensitivity, save costs, and increase the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

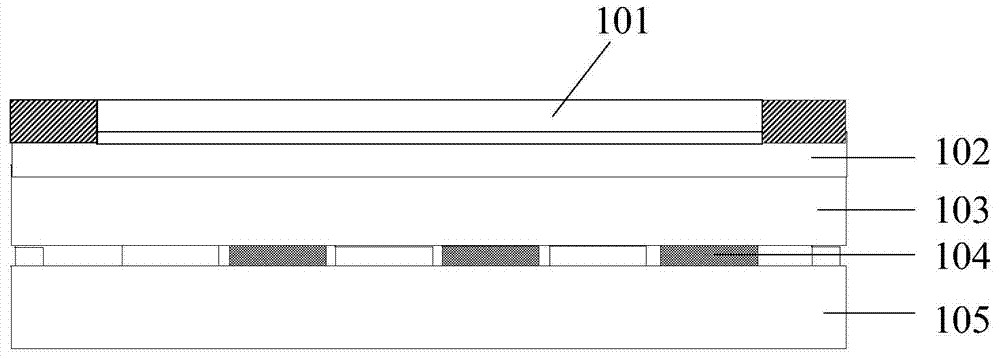

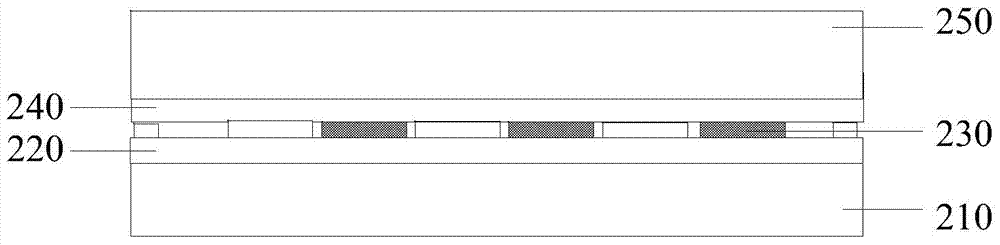

[0052] Existing touch displays have a large thickness and complex manufacturing process, and need to separately bond the touch layer to the display panel. When bonding, the touch layer is easily disturbed or damaged, and the manufacturing cost and process time are also increased. It consumes more materials and manpower, and in terms of performance, the brightness of the display is reduced.

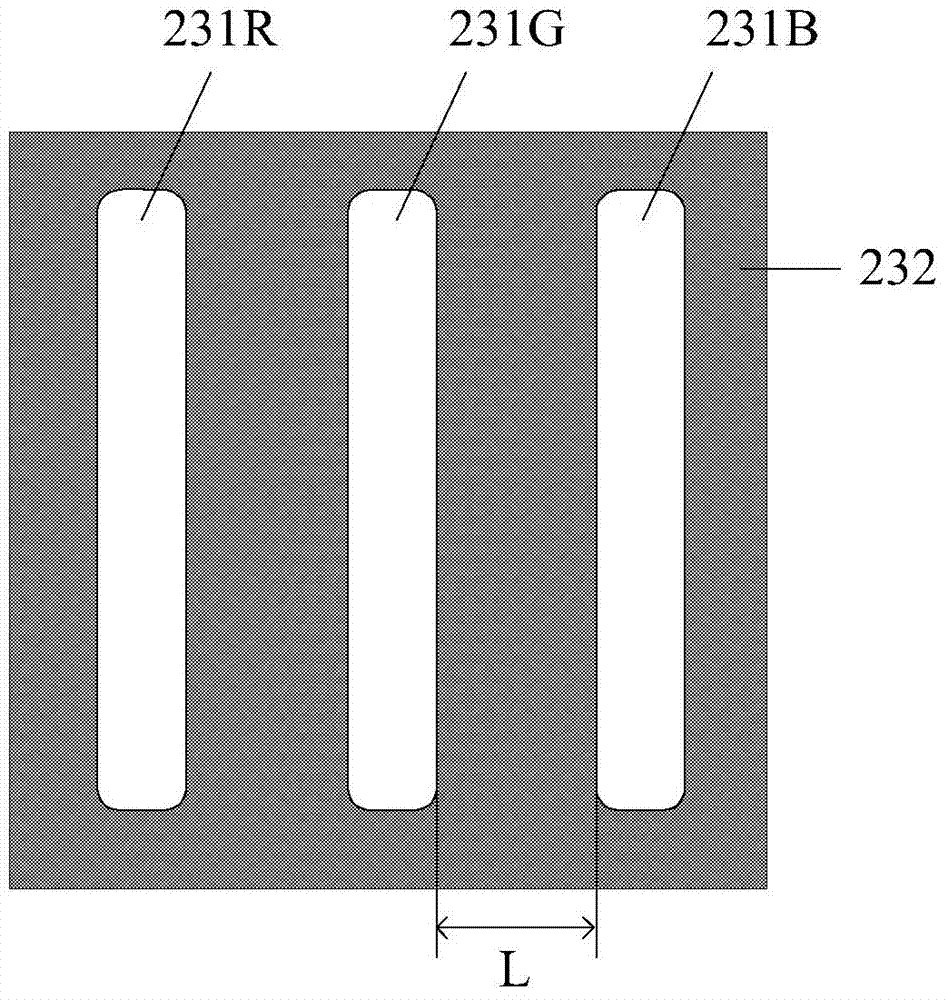

[0053]To this end, the present invention provides a new touch display panel. The touch display panel arranges the touch layer between the packaging substrate and the array substrate, thereby preventing the subsequent bonding process of the touch display panel with the cover plate. damage to the touch layer, and because the touch layer is directly arranged on the OLED layer, there is no need to set a separate touch layer substrate, so at least one substrate can be reduced. At the same time, because the touch layer is directly arranged on the substrate of the display panel In addition, proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com