Fully automatic reinforcing machine

It is a kind of pasting and strengthening and fully automatic technology, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc. It can solve the problems of small size of metal sheet, high scrap rate of circuit board, insufficient pressing force and unstable bonding, etc. Production cost, the effect of reducing the adverse effects of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

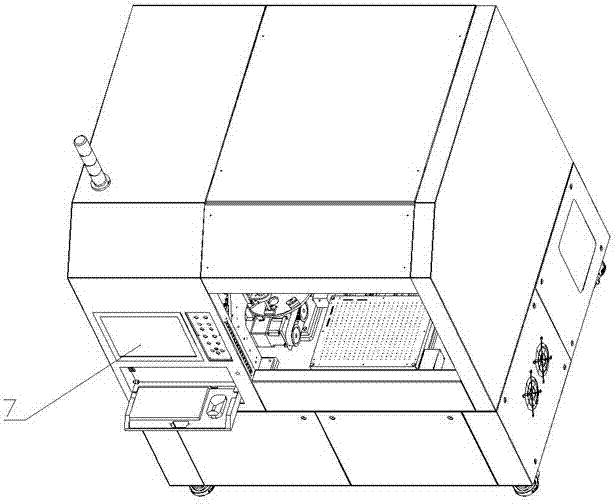

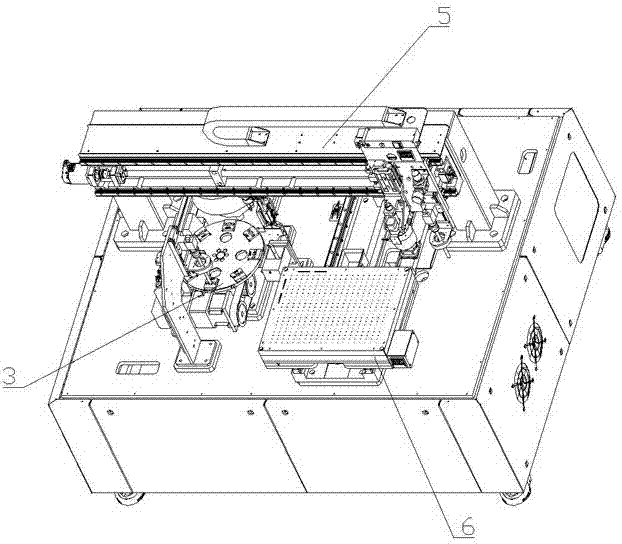

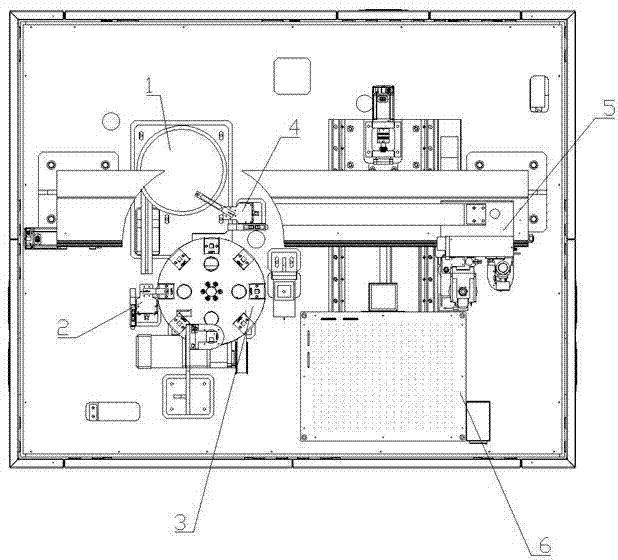

[0022] Such as figure 1 , figure 2 and image 3 As shown, the cabinet of the present invention, the control device and the vibration feeding device 1 electrically connected with the control device, the feeding manipulator 2, the indexing and screening device 3, the board mounting device 5 and the table adsorption device 6, the vibration feeding device 1 , the feeding manipulator 2, the indexing and screening device 3 and the table adsorption device 6 are all arranged on the workbench of the cabinet, and the board attaching device 5 is arranged on the gantry support of the cabinet. The control device activates the vibrating feeding device 1 to vibrate the reinforcing plate to the discharge port, suck it up by the feeding manipulator 2 and send it to the indexing and screening device 3 for screening, and the qualified ones are then sent to the discharge port. The sticking device 5 sucks it away, adjusts the appropriate angle and position, and sticks it to the FPC board pla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap