rolling bearing

A technology for rolling bearings and bearing inner rings, applied in the field of rolling bearings, can solve problems such as high manufacturing costs, large coating equipment and electroplating pools, and economical manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

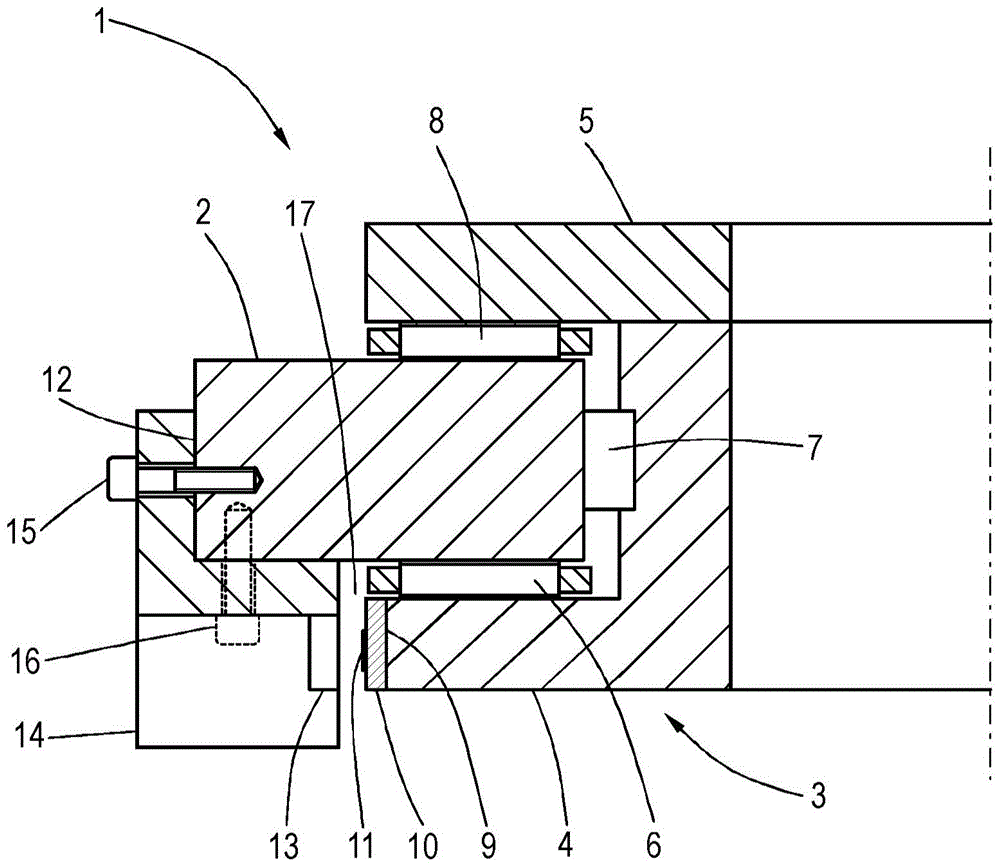

[0016] The rolling bearing 1 shown in the drawing comprises a fixed bearing outer ring 2 and a bearing inner ring 3 which is rotatable relative to the bearing outer ring 2 . The bearing inner ring 3 essentially comprises an angular ring 4 which is connected to an angular disc 5 . As shown in the figures, the angle ring 4 and the shaft disc 5 together approximately form a C-shaped profile, which includes raceways for the rolling bodies 6 , 7 , 8 . The rotatable bearing inner ring 3 is mounted rotatably in the bearing outer ring 2 via rolling elements 6 , 7 , 8 .

[0017] The angle ring 4 has an annular cylindrical contact surface 9 for the measuring ring 10 . The measuring ring 10 is connected to the bearing inner ring 3 , more precisely to the angle ring 4 by means of a force fit. The measuring ring 10 has an inductively detectable measuring standard 11 on its outer side. In the exemplary embodiment shown, measuring standard 11 comprises a plurality of parallel axial stripe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com