Thread detection system for underwater stay horizontal type granulator and detection method thereof

A detection system and pelletizer technology, which are applied in radiation pyrometry, measuring devices, optical radiation measurement, etc., can solve the problems of high false alarm rate, difficulty in meeting the special space installation requirements of horizontal machines, and inaccurate detection results. , to achieve the effect of strong real-time performance, avoiding false alarm defects, and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

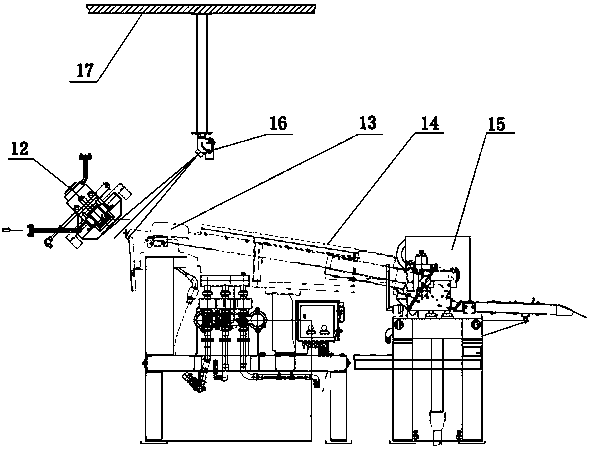

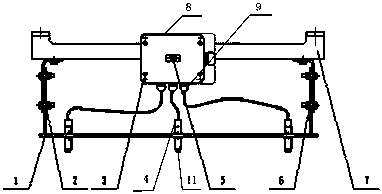

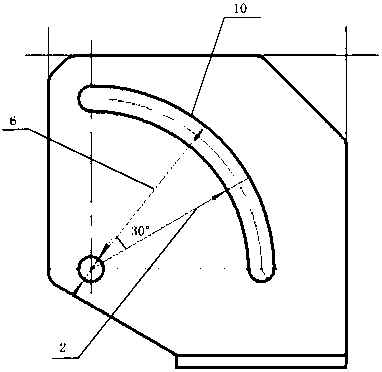

[0034] Such as Figure 1-3 As shown, a wire strand detection system for an underwater sliver horizontal pelletizer includes a casting head 12, a starting head 13, a guide groove 14 and a cutting chamber 15, and the casting head 12 and the guide groove 14 are provided with a gap, One end of the guide groove 14 near the casting head 12 is movably provided with a start head 13, the other end of the guide groove 14 is connected to the cutting chamber 15, and the start head 13 is arranged to accept the cast head 12; it also includes a non-contact setting on the start head 13 The wire strand detection device 16 on the top and relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com