Automatic horizontal centrifuge

A horizontal centrifuge, automatic technology, applied in the direction of centrifuges, etc., can solve the problems of lower processing quality, lower processing pass rate, incomplete dehydration, etc., and achieve the effect of improving processing quality, improving processing pass rate, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

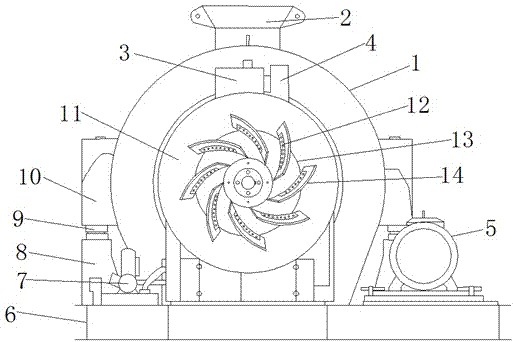

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] like figure 1 As shown, an automatic horizontal centrifuge includes a first casing 1, a second casing 10 arranged behind the first casing 1, and a bottom casing arranged under the first casing 1 and the second casing 10. Base 6, and the lubricating system 7 arranged on the top of the base 6, and the main drive motor 5 arranged on the top of the base 6 and located at the symmetrical position of the lubricating system 7, and the vibrator 11 arranged on the inside of the first casing 1, and the setting Vibration motor 3 above the vibrator 11, and the belt cover 4 that is arranged on the right side of the vibration motor 3, and the damping block 9 that is arranged on the second casing 10 below, and the support seat that is arranged on the vibration damping block 9 below 8, and the feed inlet 2 arranged above the second casing 10, and the rotor body 13 arranged inside the second casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com