Cambered displayer backboard manufacturing method and structure

A production method and display technology, applied in the direction of instruments, identification devices, etc., can solve the problems of increased difficulty of curved surfaces, aging deformation, increased manufacturing costs, etc., and achieve the effect of improving service life and product processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

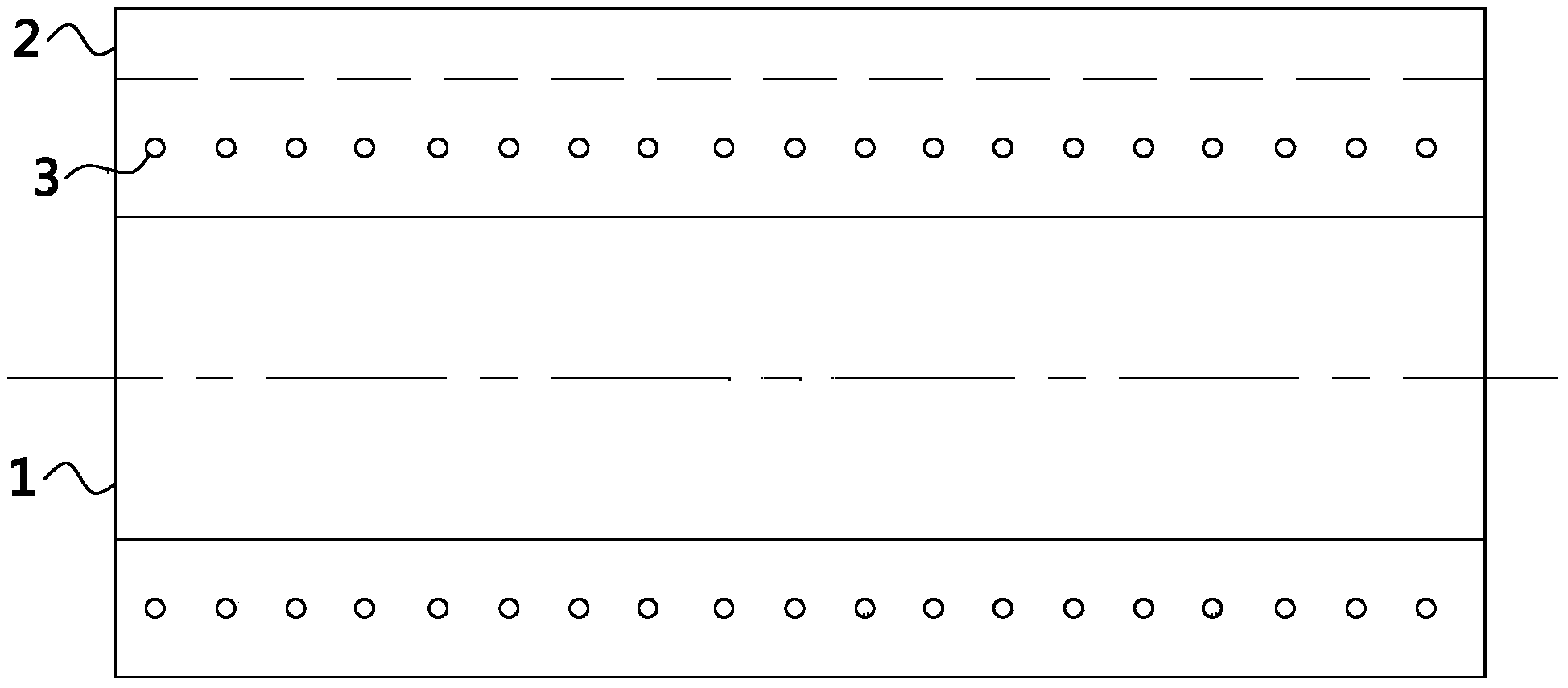

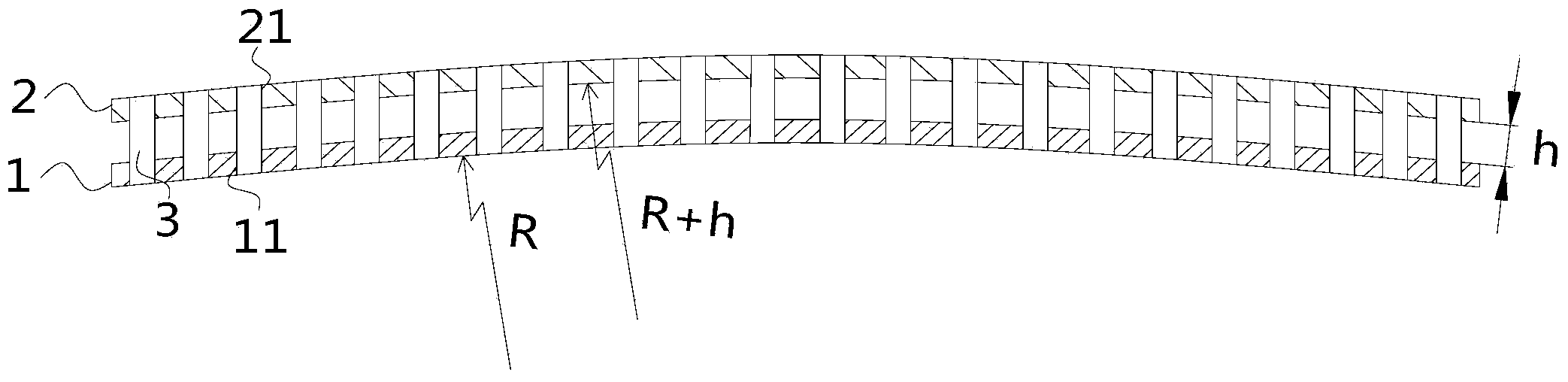

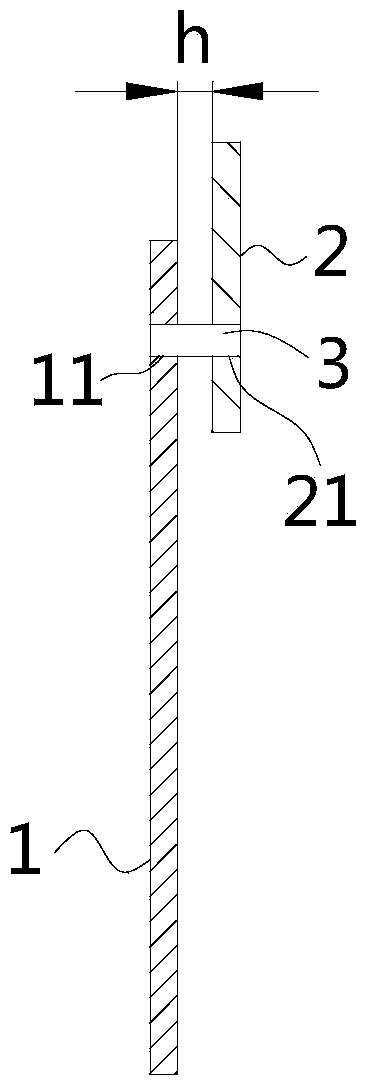

[0018] like figure 1 , figure 2 , image 3 The manufacturing method of the curved display backplane, including the carrier board 1, includes the following steps:

[0019] a. Select the carrying plate 1 and connecting plate 2, and the selected carrying plate 1 and connecting plate 2 are all flat structures;

[0020] b. Determine the bearing plate arc radius R of the bearing plate 1, calculate the spacing of the bearing plate mounting holes 11 for installing the fastening screws 3 on the bearing plate 1 according to the bearing plate arc radius R, and place the bearing plate on the bearing plate 1 Process the bearing plate mounting holes 11 at equal intervals;

[0021] c. Determine the plate spacing h between the bearing plate 1 and the connecting plate 2, determine the connecting plate arc radius (R+h) according to the plate spacing h, and determine the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com