Carbon fiber processing method and carbon fiber product

A processing method and carbon fiber technology, applied in the field of carbon fiber, to solve the effect of poor signal reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

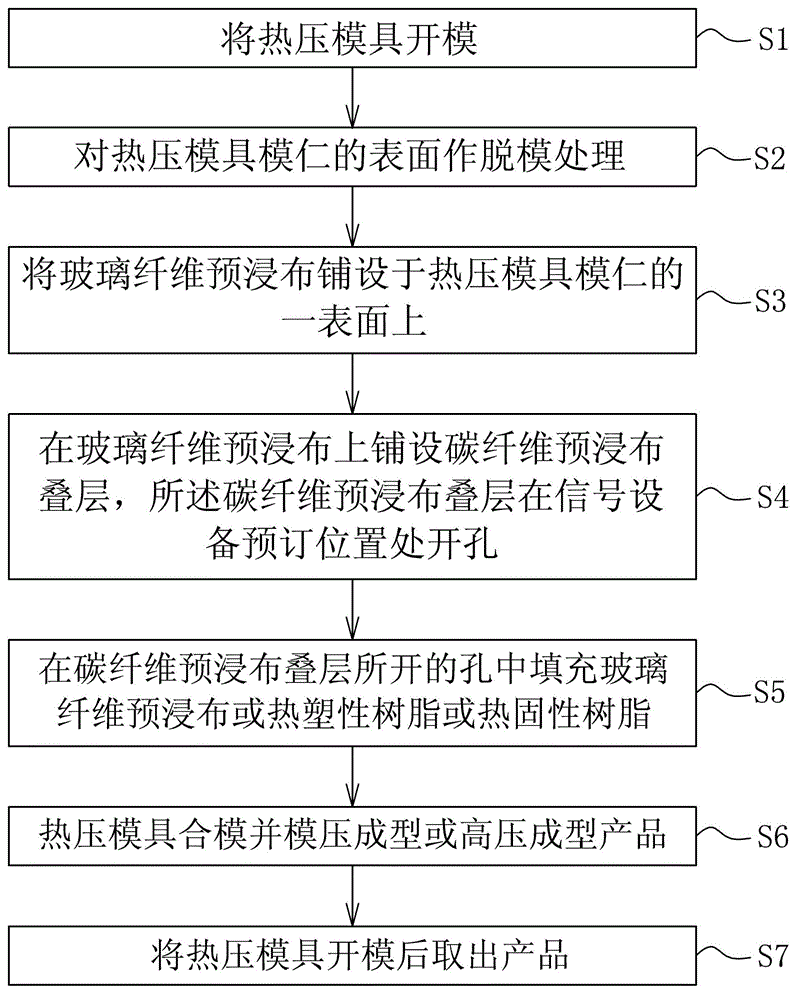

[0027] In this Example 1, please refer to figure 1 and figure 2 Shown, carbon fiber processing method of the present invention, it may further comprise the steps:

[0028] Step S1: open the hot pressing mold;

[0029] Step S2: using a release agent to perform demoulding treatment on the surface of the hot-press mold core, to prevent subsequent product sticking to the mold;

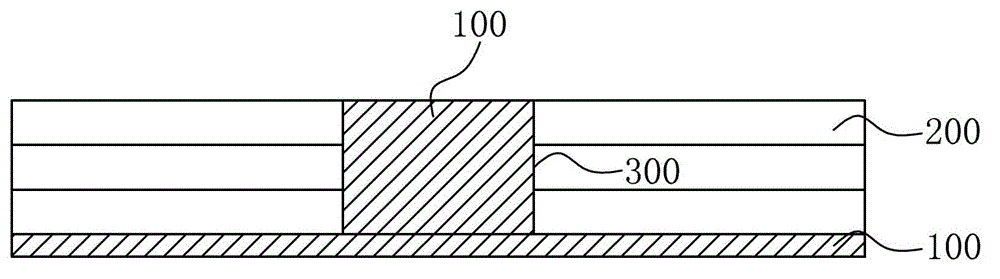

[0030] Step S3: laying the glass fiber prepreg 100 on a surface of the mold core of the hot pressing mold, as the appearance surface of the follow-up product;

[0031] Step S4: laying a carbon fiber prepreg laminate 200 on the glass fiber prepreg 100, the carbon fiber prepreg laminate 200 has a hole 300 at a predetermined position of the signal device, and the opening 300 is in the form of carbon fiber Reserving a hole 300 on the impregnated cloth laminate 200 or milling the hole 300 on the carbon fiber impregnated cloth laminate 200;

[0032] Step S5: filling the glass fiber prepreg 100 in the hole 3...

Embodiment 2

[0036] In this Example 2, please refer to figure 1 and image 3 Shown, carbon fiber processing method of the present invention, it may further comprise the steps:

[0037] Step S1: open the hot pressing mold;

[0038] Step S2: using a release agent to perform demoulding treatment on the surface of the hot-press mold core, to prevent subsequent product sticking to the mold;

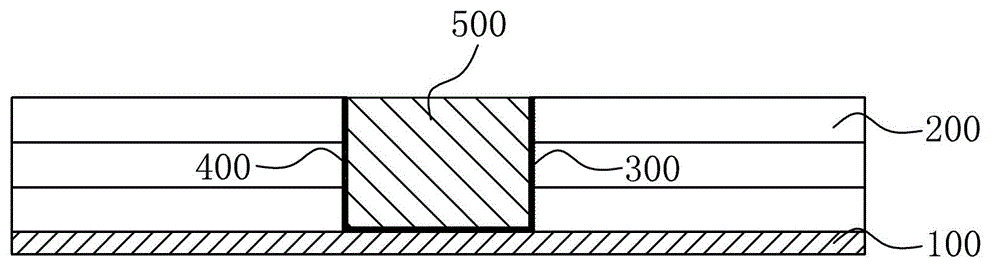

[0039] Step S3: laying the glass fiber prepreg 100 on a surface of the mold core of the hot pressing mold, as the appearance surface of the follow-up product;

[0040] Step S4: laying a carbon fiber prepreg laminate 200 on the glass fiber prepreg 100, the carbon fiber prepreg laminate 200 has a hole 300 at a predetermined position of the signal device, and the opening 300 is in the form of carbon fiber Reserving a hole on the impregnated cloth laminate 200 or milling a hole 300 on the carbon fiber impregnated cloth laminate 200;

[0041] Step S5: Apply glue 400 on the side wall of the hole 300 opened o...

Embodiment 3

[0045] In this Example 3, please refer to figure 1 and Figure 4 Shown, carbon fiber processing method of the present invention, it may further comprise the steps:

[0046] Step S1: open the hot pressing mold;

[0047] Step S2: using a release agent to perform demoulding treatment on the surface of the hot-press mold core, to prevent subsequent product sticking to the mold;

[0048] Step S3: laying the glass fiber prepreg 100 on the surface of the core of the hot pressing mold as the appearance surface of the follow-up product;

[0049] Step S4: laying a carbon fiber prepreg laminate 200 on the glass fiber prepreg 100, on the carbon fiber prepreg laminate 200, a hole 300 is opened at a predetermined position of the signal device, and the opening 300 is made in a carbon fiber A hole 300 is reserved on the impregnated cloth laminate 200 or a hole 300 is milled on the carbon fiber impregnated cloth laminate 200. A hook 310 is provided on the side wall of the hole 300. The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com