Webbing take-up device

一种卷绕装置、安全带的技术,应用在车内安全带、皮带收紧器、运输和包装等方向,能够解决配合余量增大、爪部难以通过窗部、组装性变差等问题,达到增大对置面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] (Structure of this embodiment)

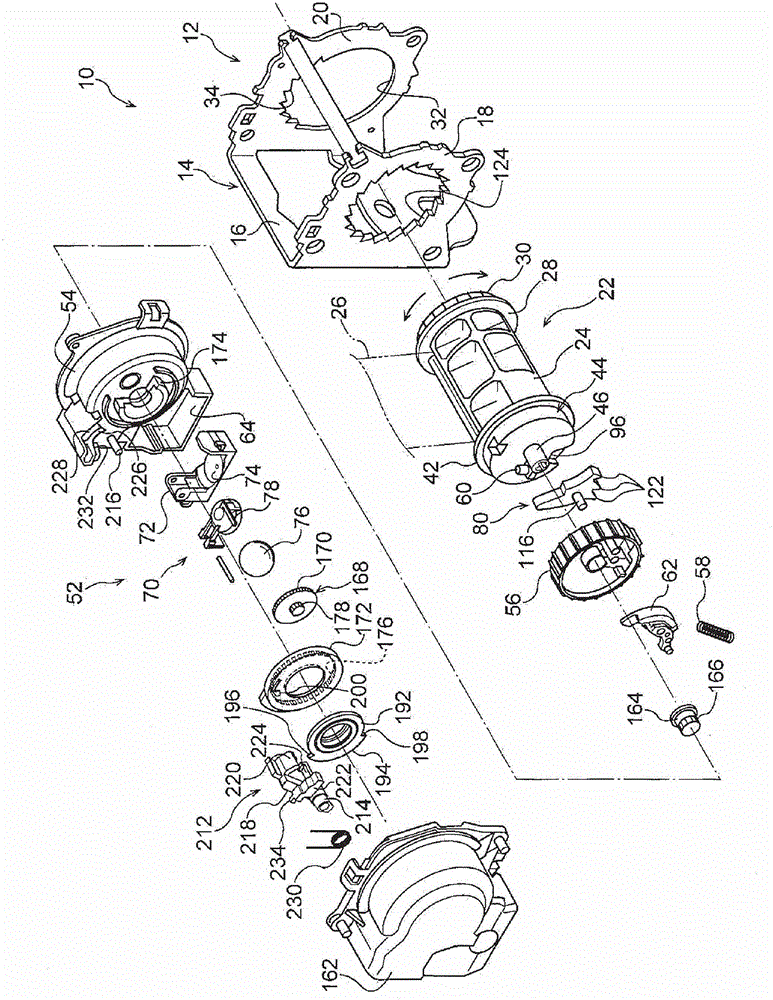

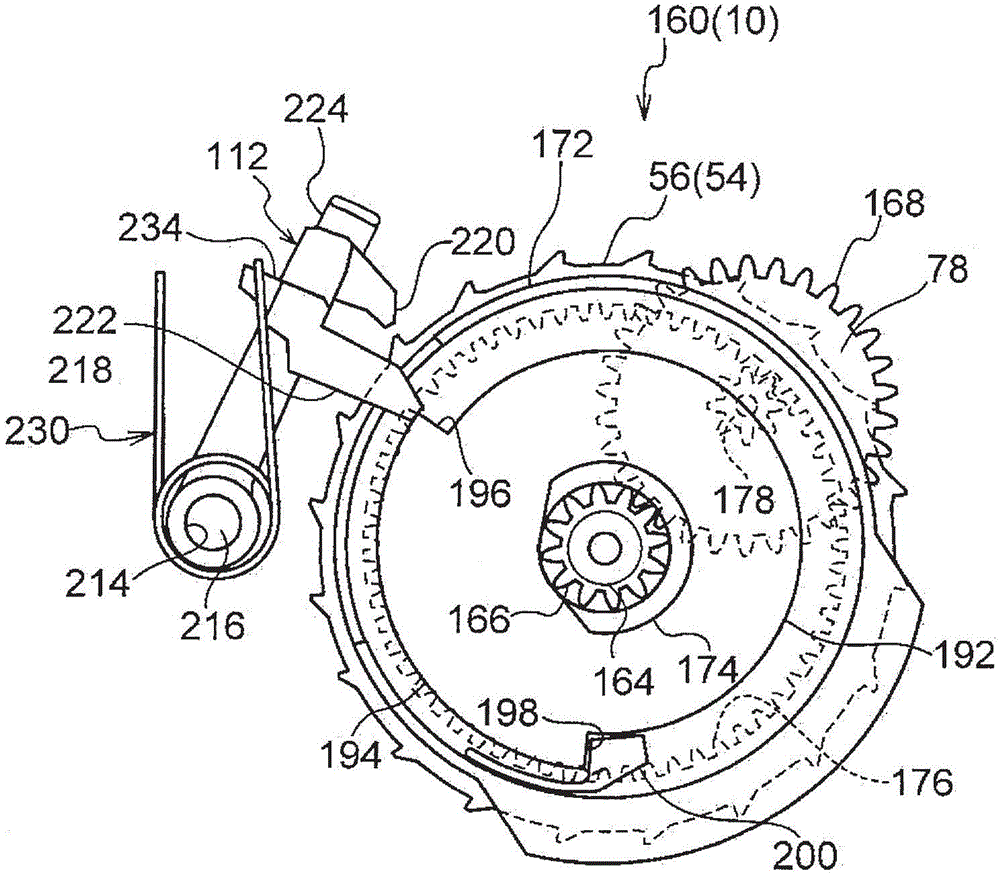

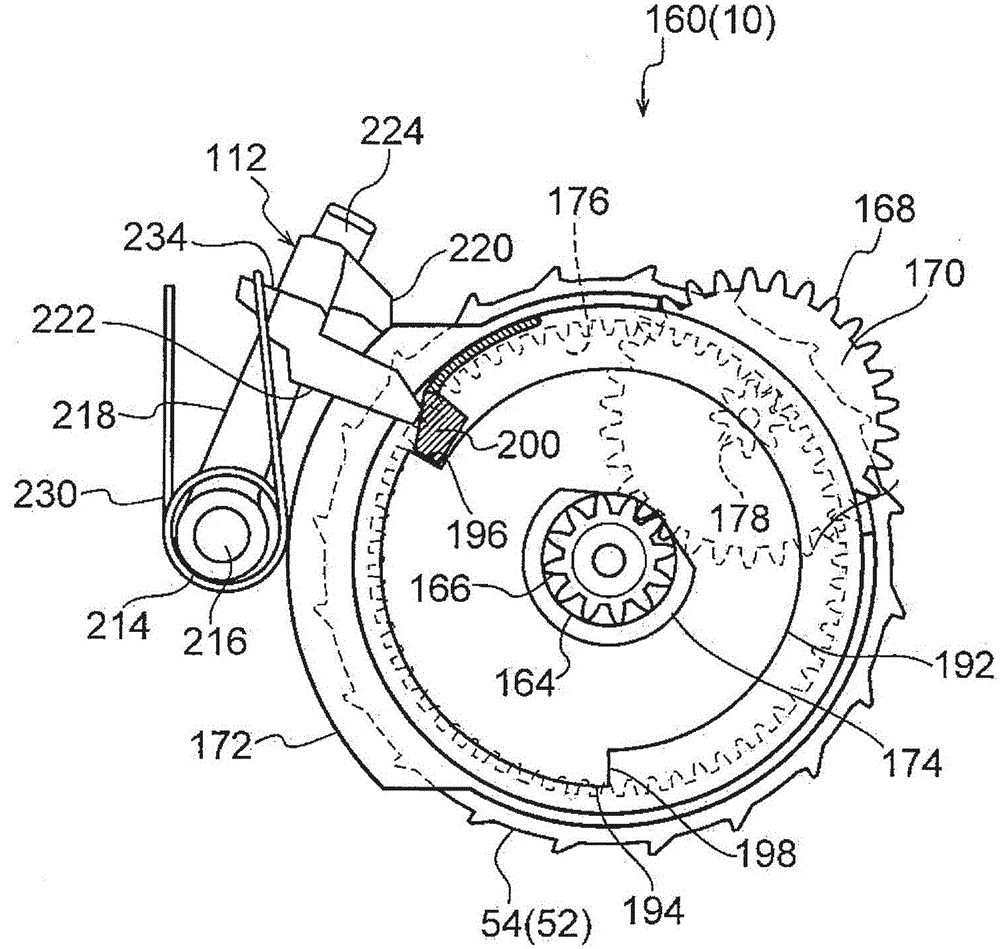

[0029] figure 1 The outline of the whole structure of the seat belt retractor 10 which concerns on one Embodiment of this invention is shown using an exploded perspective view in .

[0030] The device body 12 of the seat belt take-up device 10 includes a frame 14 . The frame 14 includes a plate-shaped back plate 16 . Extend and protrude from one end of the width direction of the backboard 16 to one side of the thickness direction of the backboard 16, and protrude from the other end of the width direction of the backboard 16 to one side of the thickness direction of the backboard 16 (that is, with the footboard 18 from the side of the backboard 16 The same direction as the direction in which the extension protrudes) extends and protrudes with a foot plate 20 . Therefore, the frame 14 is formed in a concave shape as a whole, and the back plate 16 of the frame 14 is directly or indirectly fixed to a frame member, a reinforcement member, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com