Armature for linear motor

A technology of linear motors and armatures, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of large pressure loss of refrigerant, large deviation of the overall temperature distribution of the armature, and long cooling pipelines, etc., to achieve reduction Effects of temperature gradient, improvement of cooling effect, and increase of facing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

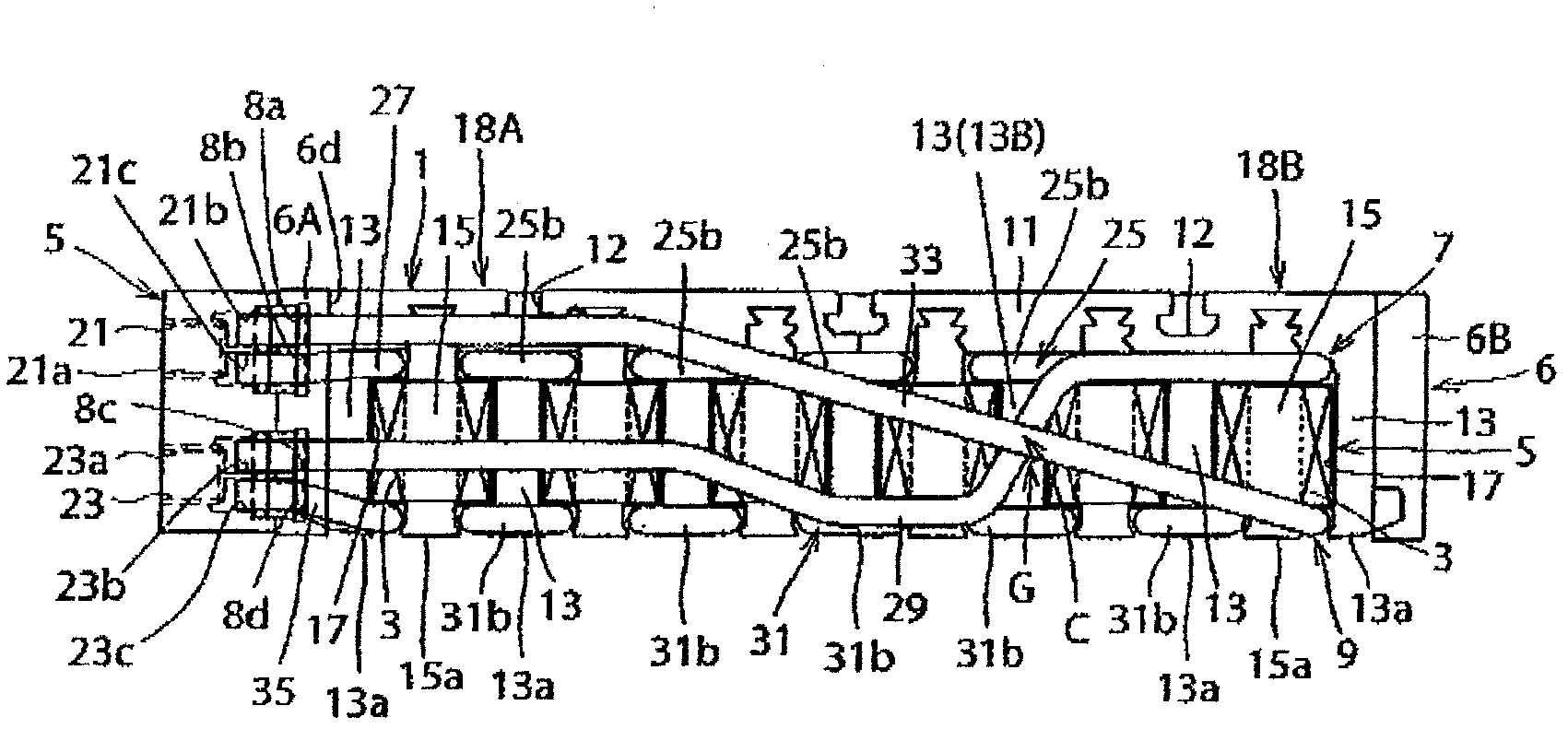

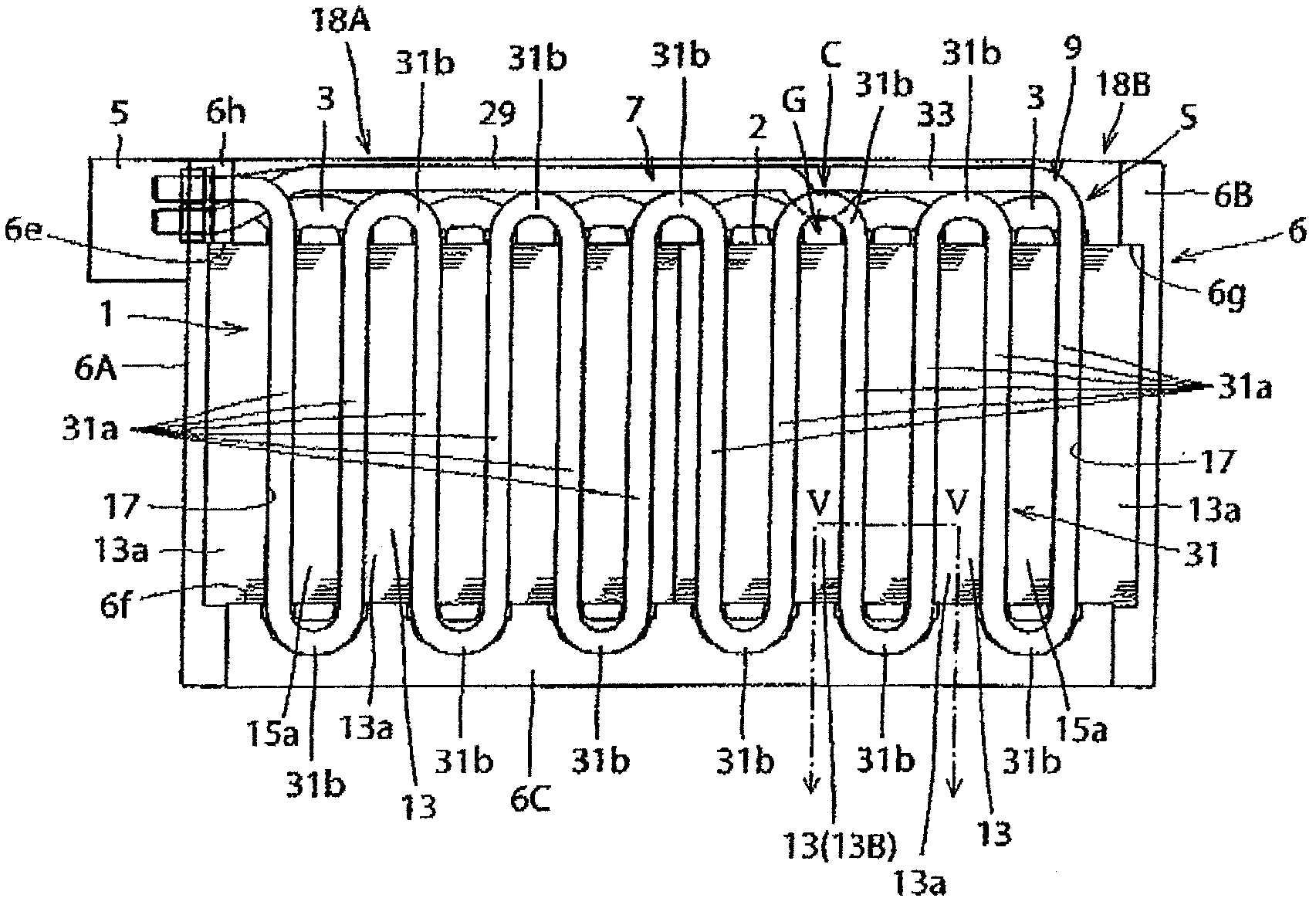

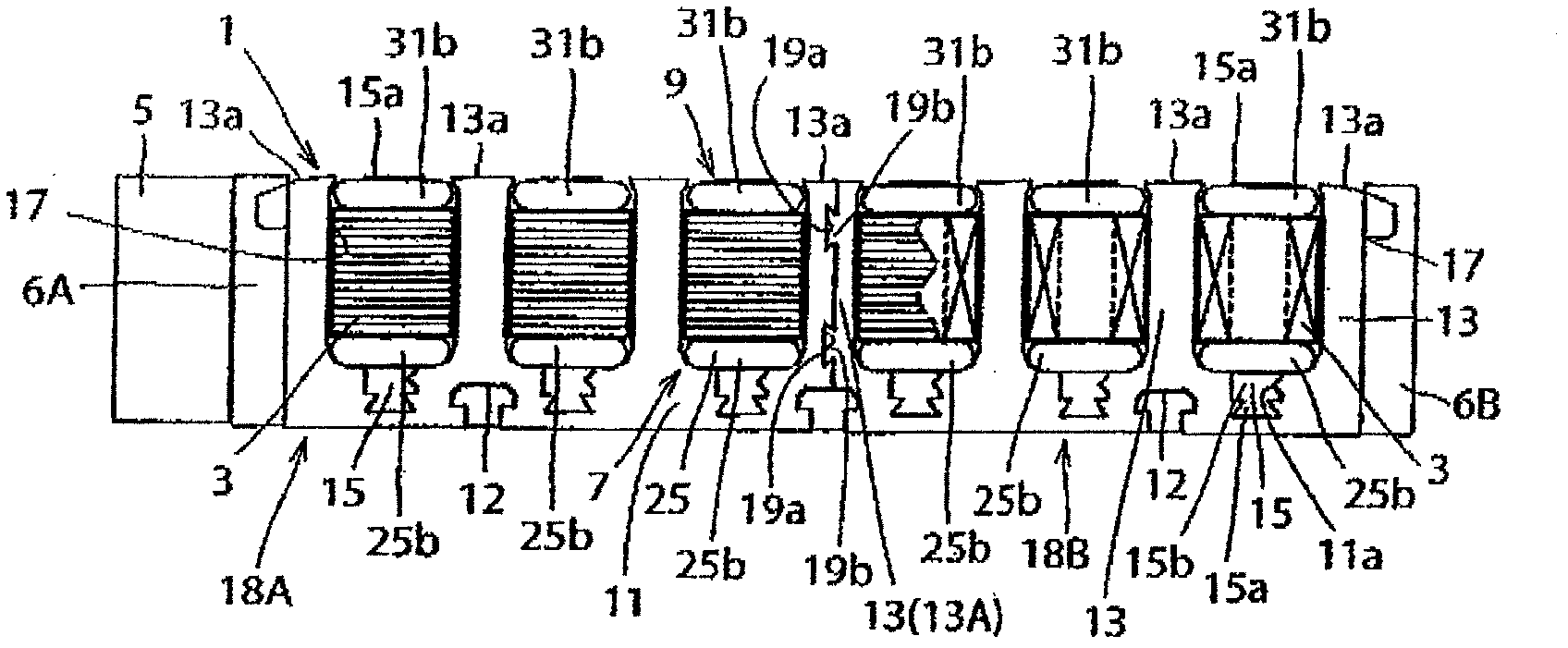

[0023] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. Figure 1 ~ Figure 4 It is a front view, a top view, a back view, and a left side view of the armature for linear motors which concerns on one Embodiment of this invention. As shown in each figure, the armature for a linear motor of this example constitutes the mover of the linear motor, and has an armature core 1, six field windings 3, a manifold main body 5, and first and second cooling lines 7, 9. The armature core 1 has a yoke 11 and thirteen pole teeth 13 , 15 . Yoke 11 facing figure 1 The paper surface extends in a straight line in the left-right direction (lengthwise direction). The thirteen pole teeth 13 and 15 are arranged along the longitudinal direction of the yoke 11 (the moving direction of the mover of the linear motor). The thirteen pole teeth are arranged at intervals in the longitudinal direction, and a slot 17 is formed between two adjacen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com