Liquid stocker, stocker driving mechanism and liquid batching system

A technology of batching system and driving mechanism, which is used in liquid processing, emptying containers, bottle filling, etc., can solve problems such as equipment cleaning, and achieve the effects of convenient and flexible use, fast installation and disassembly, and easy cleaning and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below with reference to the accompanying drawings and embodiments. In the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0039] The liquid storage device and the liquid batching system of the present invention are not only suitable for cooking condiments, but also suitable for other related liquid materials.

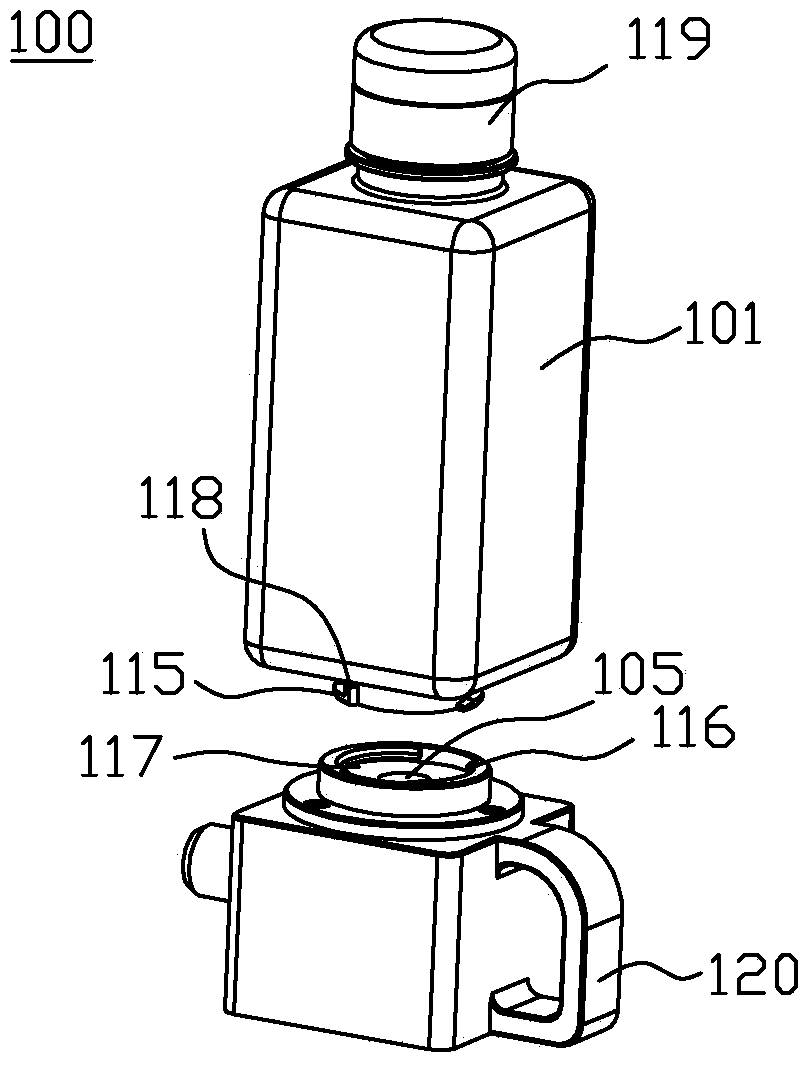

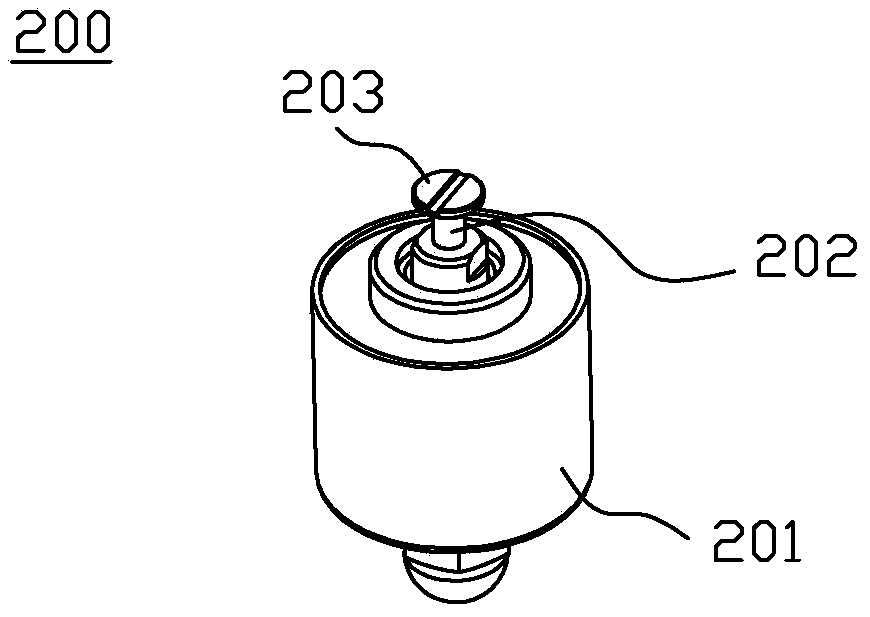

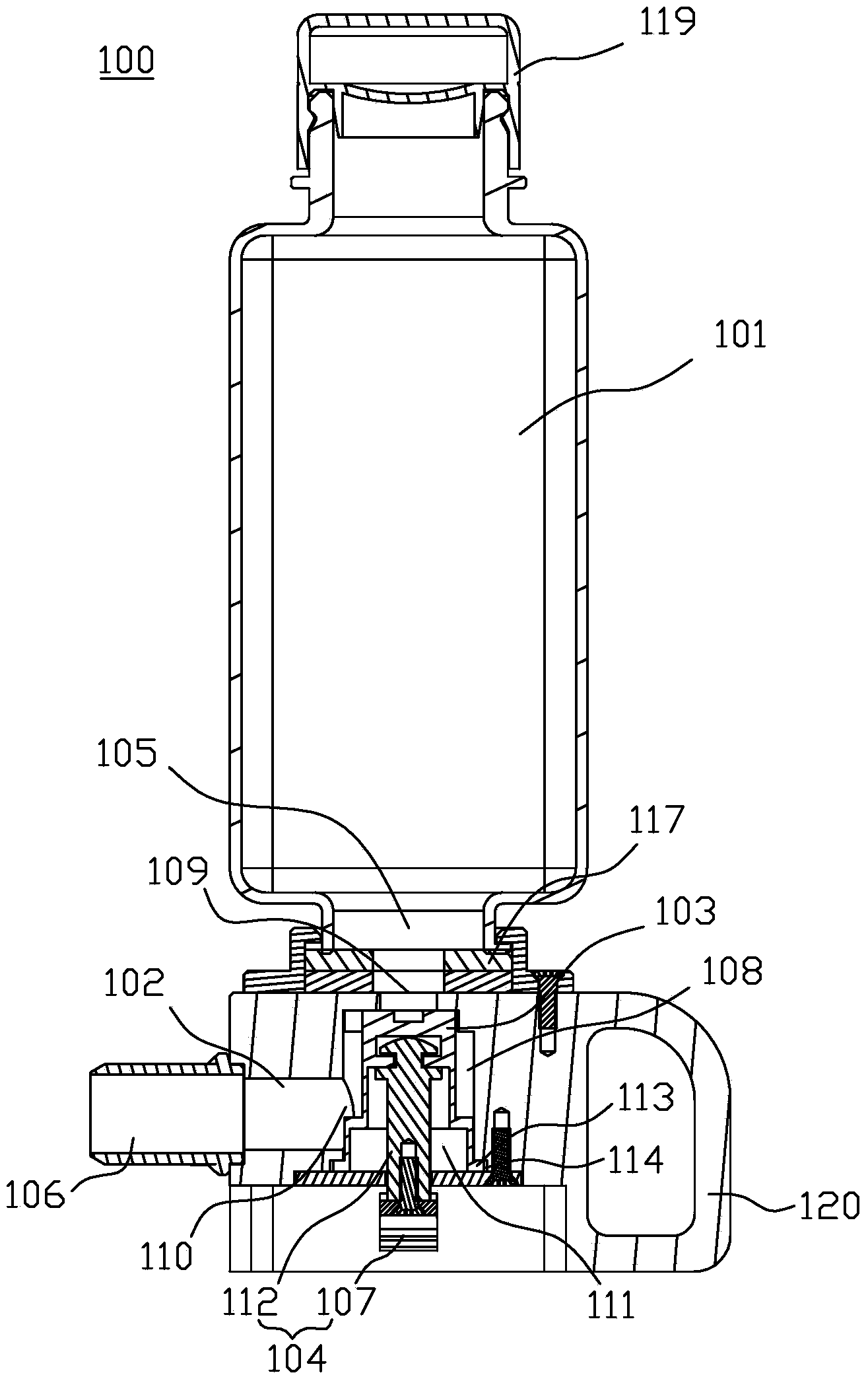

[0040] refer to Figure 1 to Figure 5 , The liquid storage device 100 of the present invention is mainly composed of a liquid storage chamber 101, a liquid channel 102, a valve 103, a first movable member 104 and the like. The liquid storage chamber 101 is used for storing liquid materials. The liquid channel 102 is provided with a liquid inlet 105 and a liquid outlet 106 , and the liquid inlet 105 communicates with the liquid storage chamber 101 . The function of the liquid channel 102 is to guide the liquid material in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com