Prefabricated superposed primary and secondary beam connecting piece and prefabricated composite primary and secondary beam connecting structure

A technology for connecting structures and connectors, applied in building structures, buildings, etc., can solve the problems of prone to oblique cracks, low structural strength, affecting building quality, etc., to avoid oblique cracks, high connection strength, and high structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

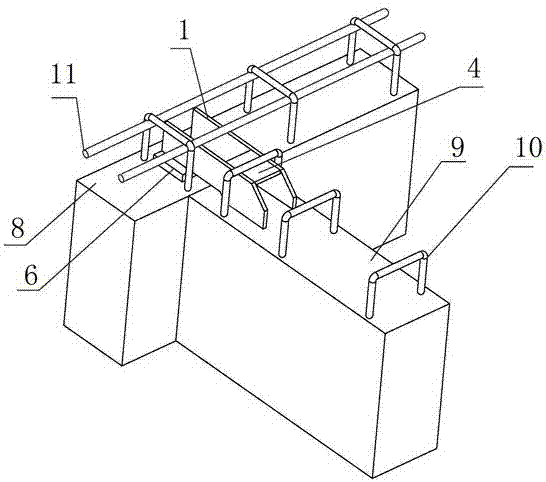

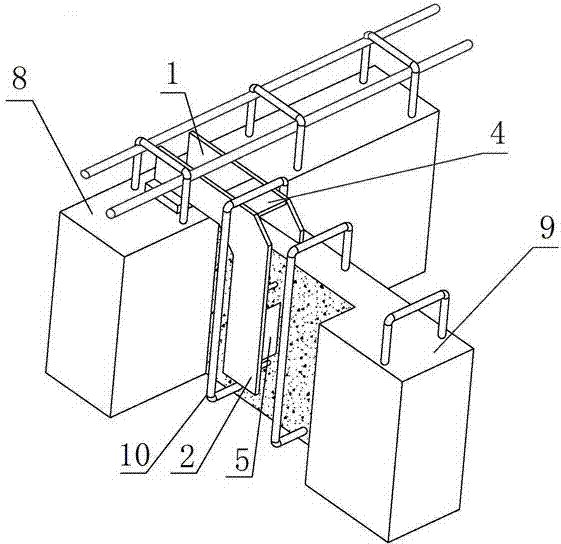

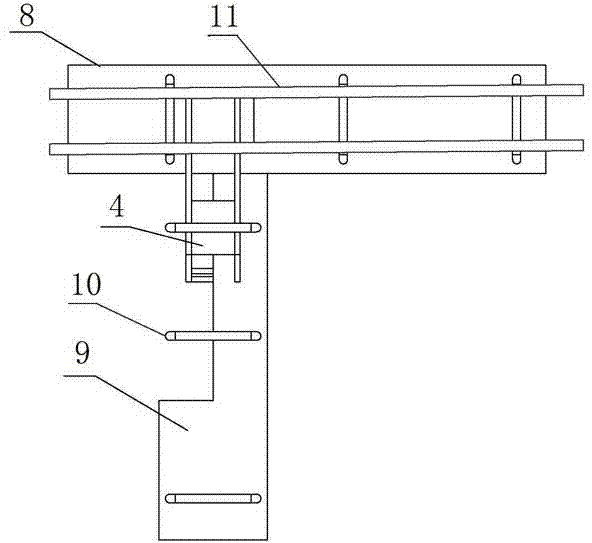

[0023] A prefabricated laminated primary and secondary beam connector of the present invention mainly includes a supporting end 1 arranged on the upper surface of the prefabricated part of the main beam and covered by the superimposed part of the main beam, prefabricated on the prefabricated part of the secondary beam and laminated by the secondary beam The partially covered prefabricated end 2, the connection part 3 connecting the support end and the prefabricated end and covered by the overlapping part of the secondary beam.

[0024] see Figure 1 to Figure 4 , in a preferred embodiment of the invention, the prefabricated laminated primary and secondary beam connectors are composed of two parallel rectangular-like steel plates connected, the horizontal side of the two parallel rectangular-like steel plates is the supporting end 1, and the vertical side is the prefabricated End 2, the plate structure connecting the horizontal side and the vertical side is the connection part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com