Method for side air supply of driving face of large-diameter deep vertical shaft

A large-diameter, vertical shaft technology, applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc., can solve problems such as the inability to effectively improve the working environment of the driving face, the restriction of conventional ventilation and dust removal functions, and the restriction of the construction of large-scale deep mines, etc. Achieving wide availability, reduced air age, improved thermal environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

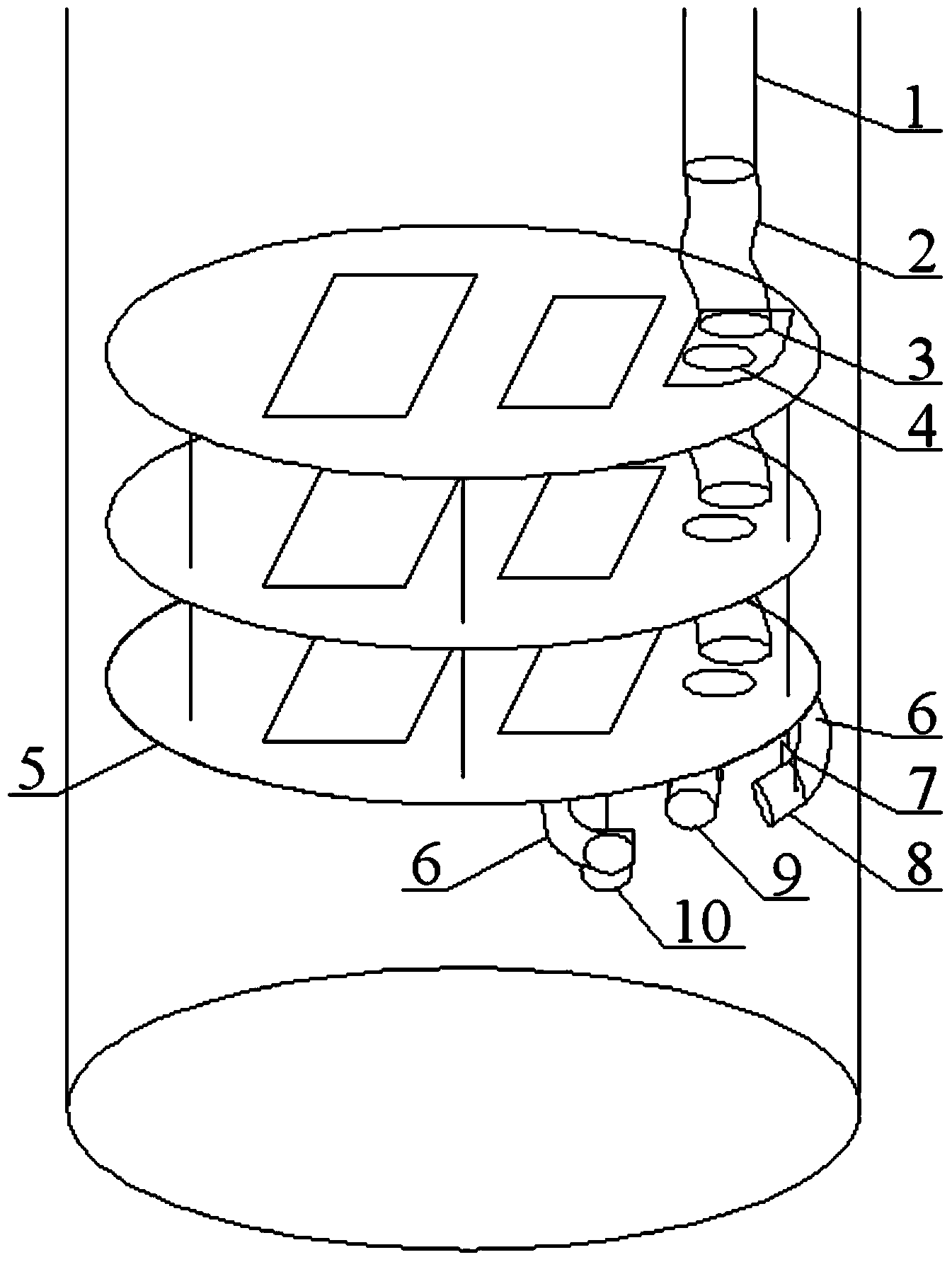

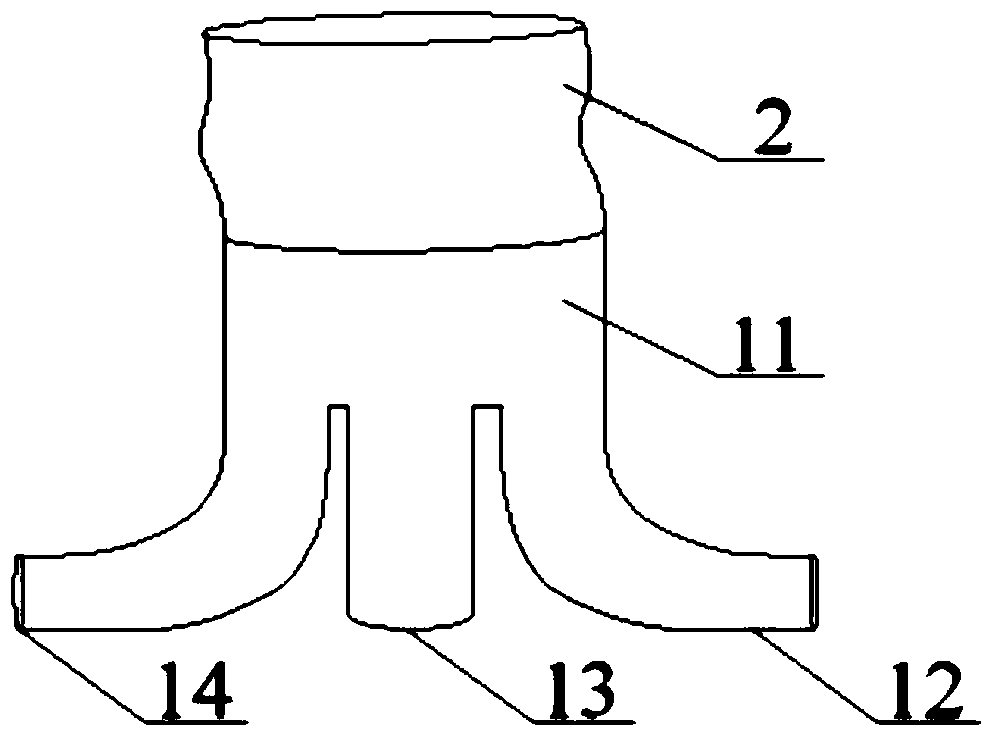

[0018] The method for supplying air to the side of the excavation face of a large-diameter deep shaft of the present invention includes setting an air supply cylinder passing through one side of the multi-layer suspension plate in the vertical shaft, and the air supply cylinder includes a main air supply cylinder 1 and a vertical flexible air cylinder 2 sequentially connected , Vertical flexible air duct hole 3. As the excavation depth of the vertical shaft continues to increase, the ambient temperature of the excavation surface gradually increases. Firstly, the three induction tuyere pipes 8, 9, and 10 are respectively fixed to the bottom of the suspension plate 5 on the last layer through the bracket 7 near the main air supply tube hole 4 to induce The air outlet pipes 8, 9, 10 are detachable and adjustable in angle, and can realize air supply in differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com