Hypersonic variable-geometry air inlet channel with rectangular section, design method and work mode

A rectangular cross-section, hypersonic technology, applied in the direction of mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve the problem that the complexity of geometric devices and the difficulty of control affect the working efficiency of the aircraft, the restart of the intake port, and the capture rate of low Mach number flow Low-level problems, to achieve the effect of simple structure, airway activation and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

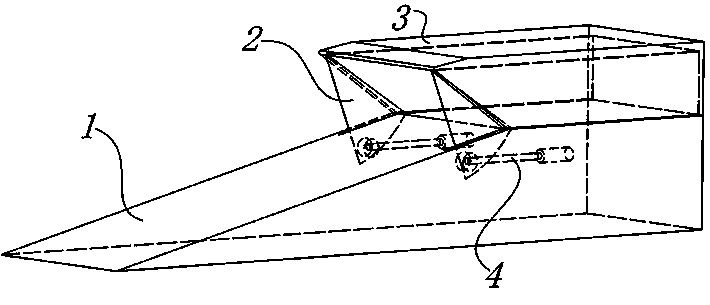

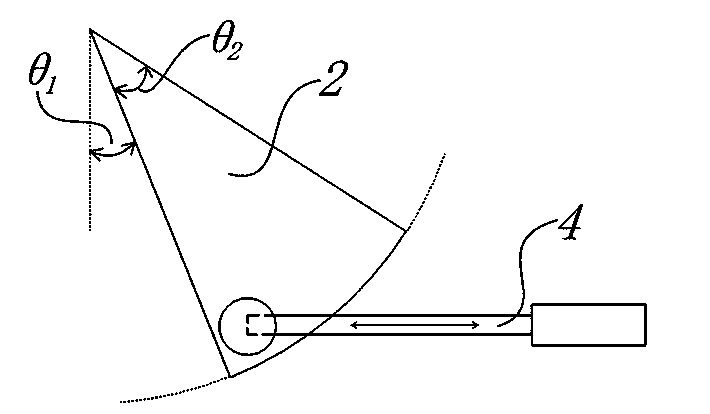

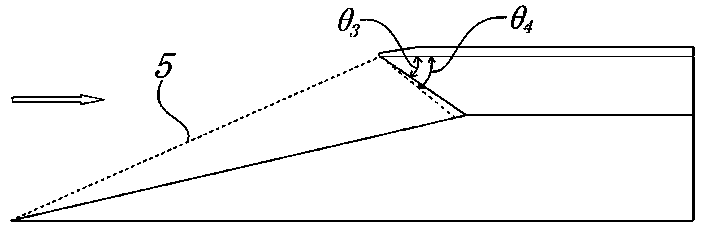

[0031] Such as figure 1 As shown, the rectangular section hypersonic variable geometry inlet of the present invention includes a hypersonic vehicle precursor 1, a lip cover adjustable side plate 2, a rectangular section lip cover 3 and a side plate actuator 4; figure 1 The hypersonic flight precursor 1 shown in is a simplified schematic diagram, and the specific form can be one of the categories of binary wedge surface compression precursor, three-dimensional curved surface compression precursor and waverider precursor in the traditional hypersonic inlet. The lip cover 3 with a rectangular cross-section is fixedly installed on the top of the hypersonic vehicle precursor 1, and the two side plate actuators 4 are symmetrically fixed and installed in the hypersonic vehicle precursor 1, and its actuation instructions come from the aircraft control system or the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com