Rotary thrust vectoring nozzle for short-distance vertical take-off and landing engine

A technology of vertical take-off and landing and thrust vectoring, applied in the aviation field, can solve the problem of increasing the difficulty of nozzle design, and achieve the effect of scientific nozzle profile design, complete mechanical structure, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

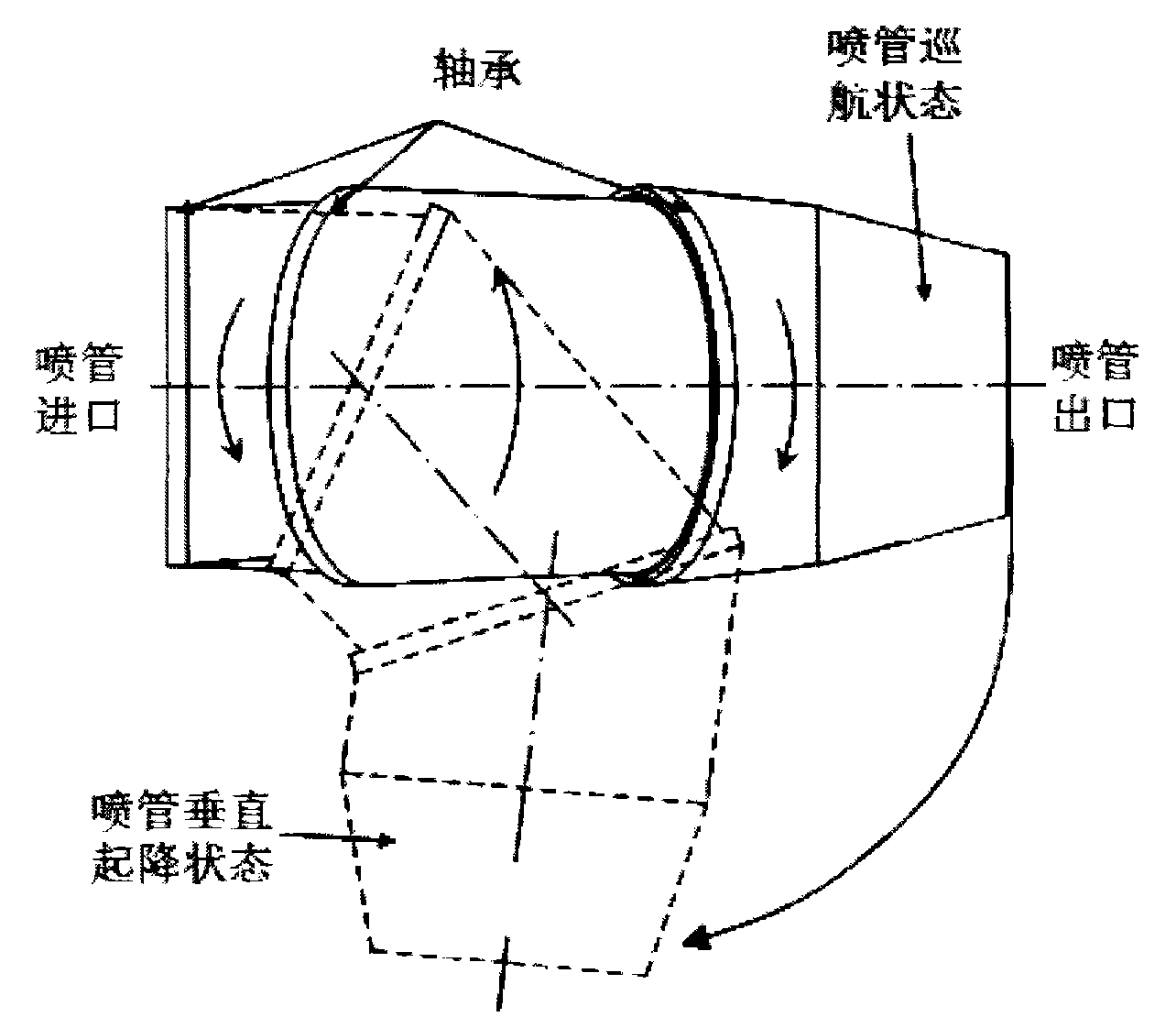

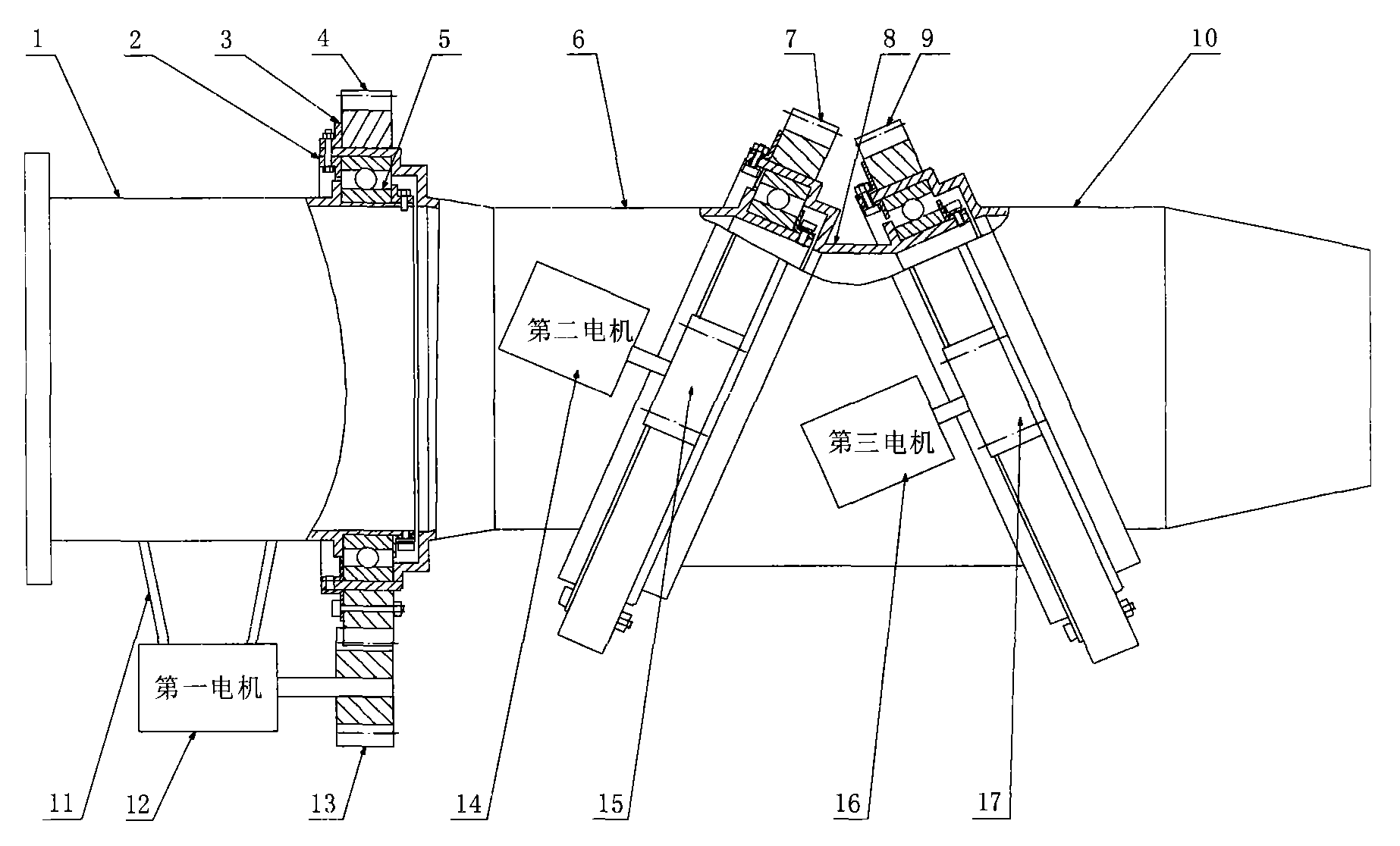

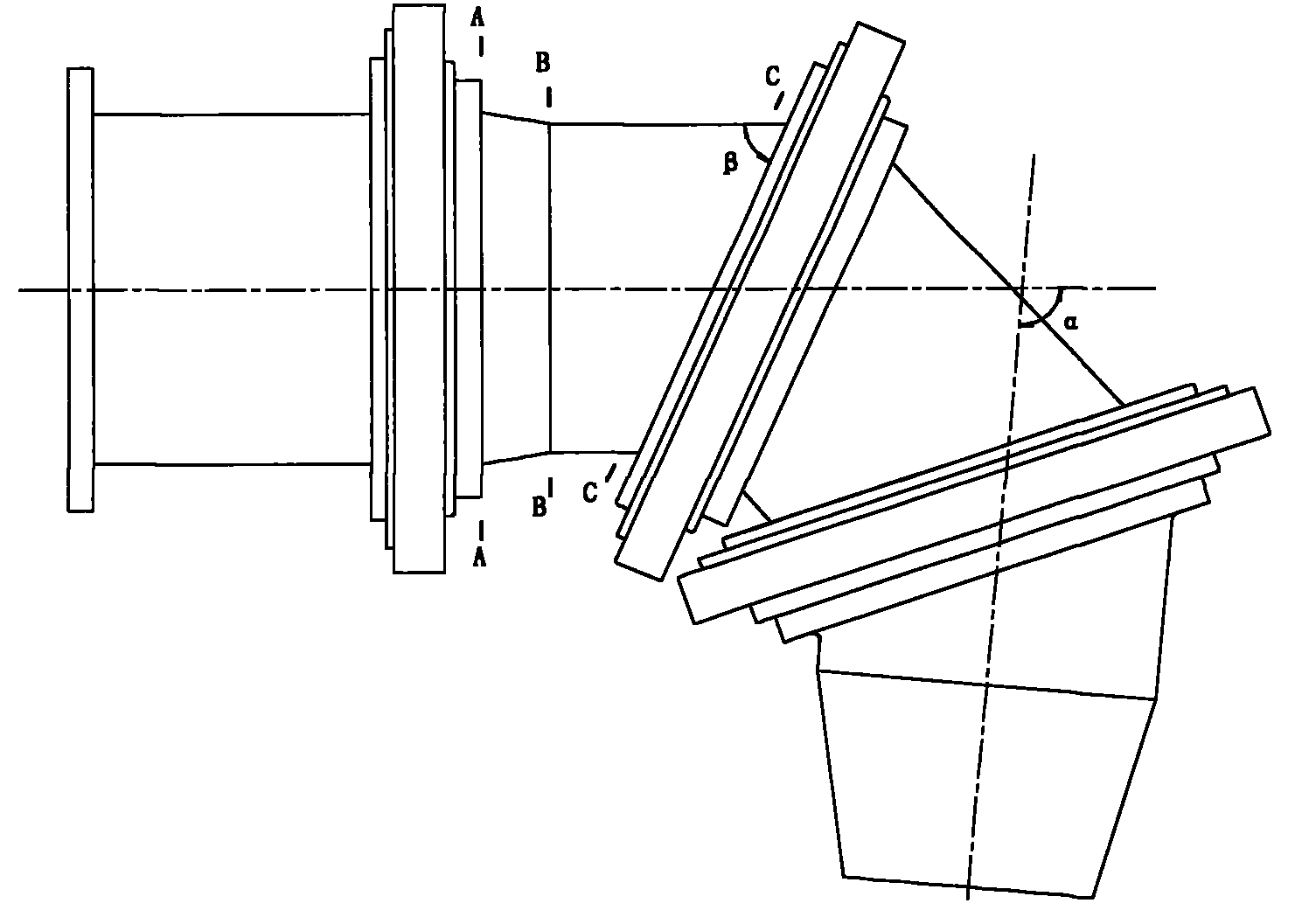

[0020] Specific implementation: Relying on the jetcat small turbojet engine test bench, the size of each section of the rotary thrust vectoring nozzle is designed with reference to the jetcat original nozzle size design, and the bearings are standard deep groove ball bearings. The rotating cylinder of the first section of the nozzle adopts the law of uniform speed control, and the rotation range is 0-95°. From this, the maximum deflection vector angle of the nozzle is α=95°, and β=90-α / 4=66.25°. Due to the non-linear rotation angle law between the three sections of the barrel, the second and third sections of the nozzle adopt the variable speed control law.

[0021] figure 2 Among them, start the first, second and third motors 12, 14, 16 simultaneously, the first motor 12 drives the first driving gear 13 to rotate, and the first transmission gear 4 meshes with the first driving gear 13, because the first transmission gear 4 and the first driving gear 13 are in mesh with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com