Compatibility-Based Measuring Test Device for Refrigerant Compressor Oil Circulation Rate

A compressor oil and test device technology, which is applied in pump testing, mechanical equipment, machines/engines, etc., can solve problems such as poor accuracy, and achieve the effects of ensuring accuracy, improving low oil return efficiency, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

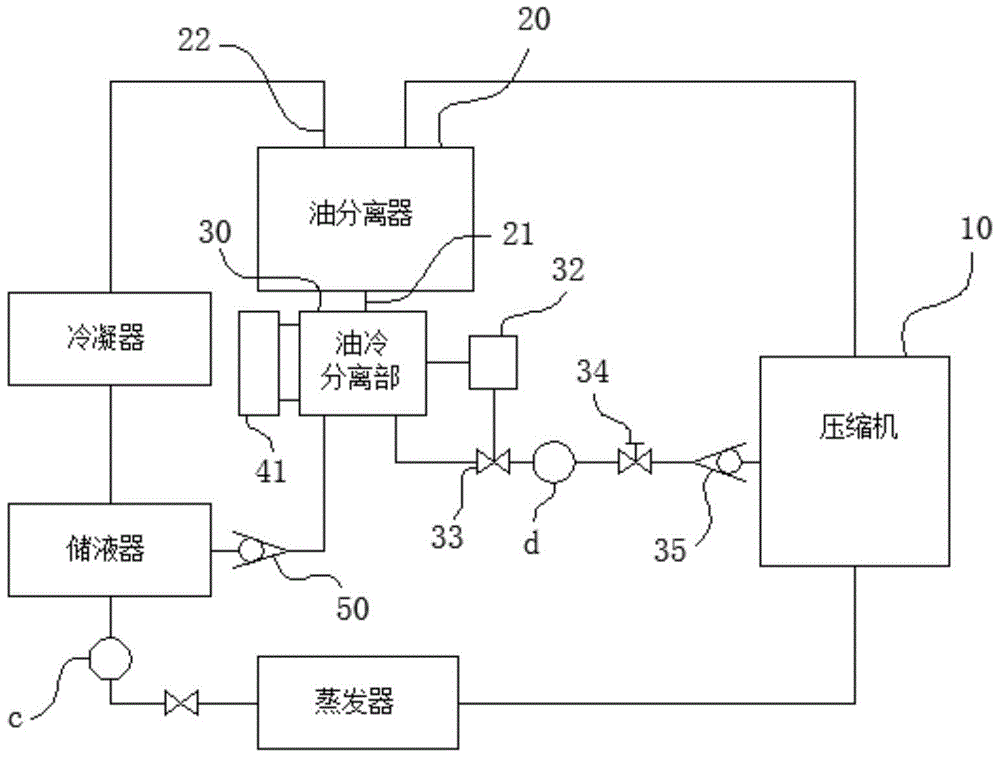

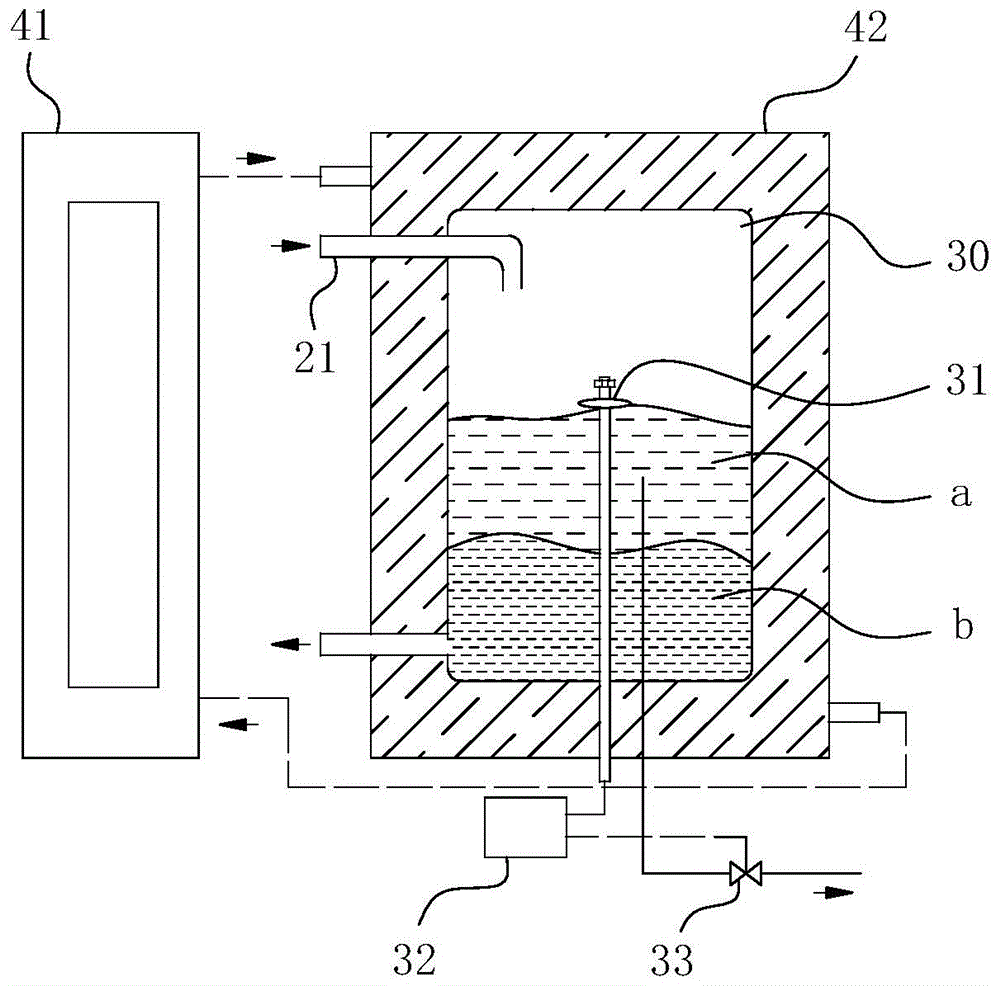

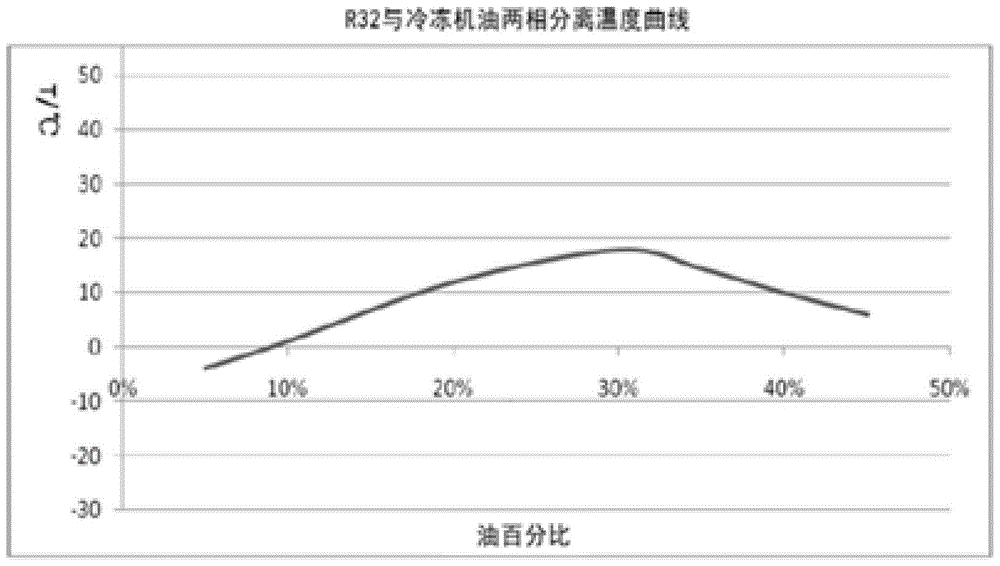

[0030] For ease of understanding, the combination of refrigerant R32 and Figure 1-3 Specifically set forth the component structure of the present invention and its specific working process; R32 is a hot spot refrigerant replaced by HCFC (hydrochlorofluorocarbon), and it is miscible with refrigerator oil most of the time under the working temperature of the oil separator in the refrigeration system. It is impossible to completely separate in the oil separator 20, and it is most convenient to explain the invention focus of the present invention by using it as a representative description. When the traditional oil separation method is used to measure the oil circulation rate of the R32 refrigeration compressor, some refrigerant is inevitably dissolved in the oil circuit measurement circuit, resulting in a relatively small flow rate in the refrigerant circuit and a large flow rate in the oil circulation circuit. After part of the refrigerant is too large, the measurement data of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com