Double-lever type power energy-saving device

An energy-saving device and double-lever technology, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of high consumption of non-renewable energy, low utilization rate of power and power, and increased mechanical operation cost, and achieves a simple structure. , The effect of high mechanical transmission efficiency and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

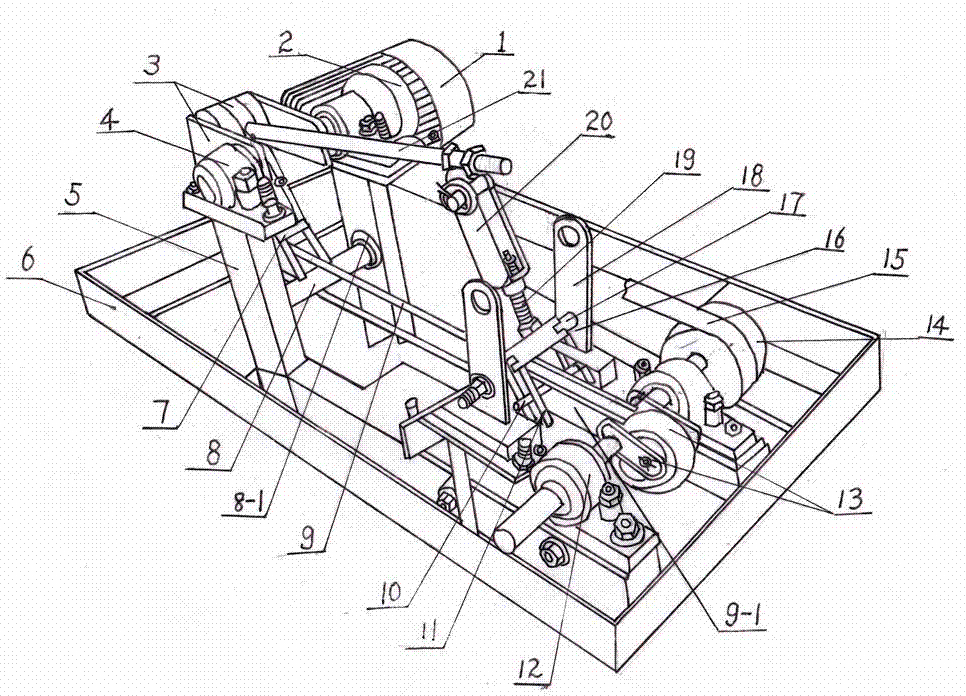

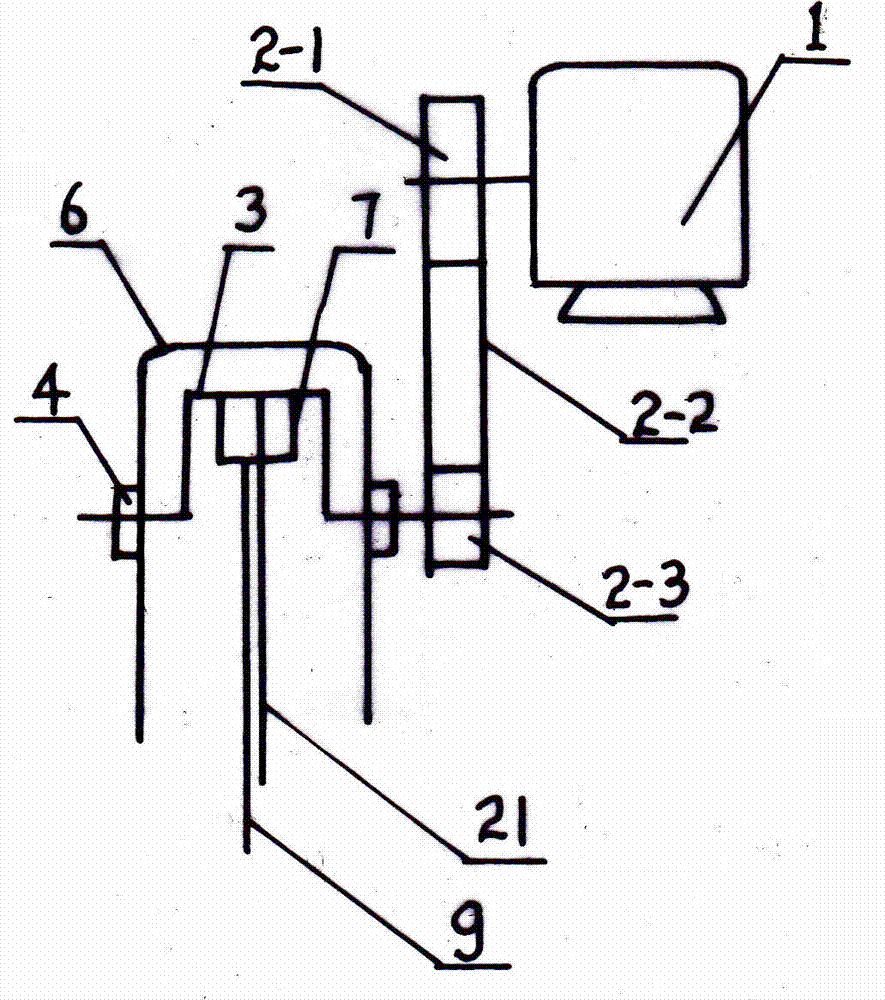

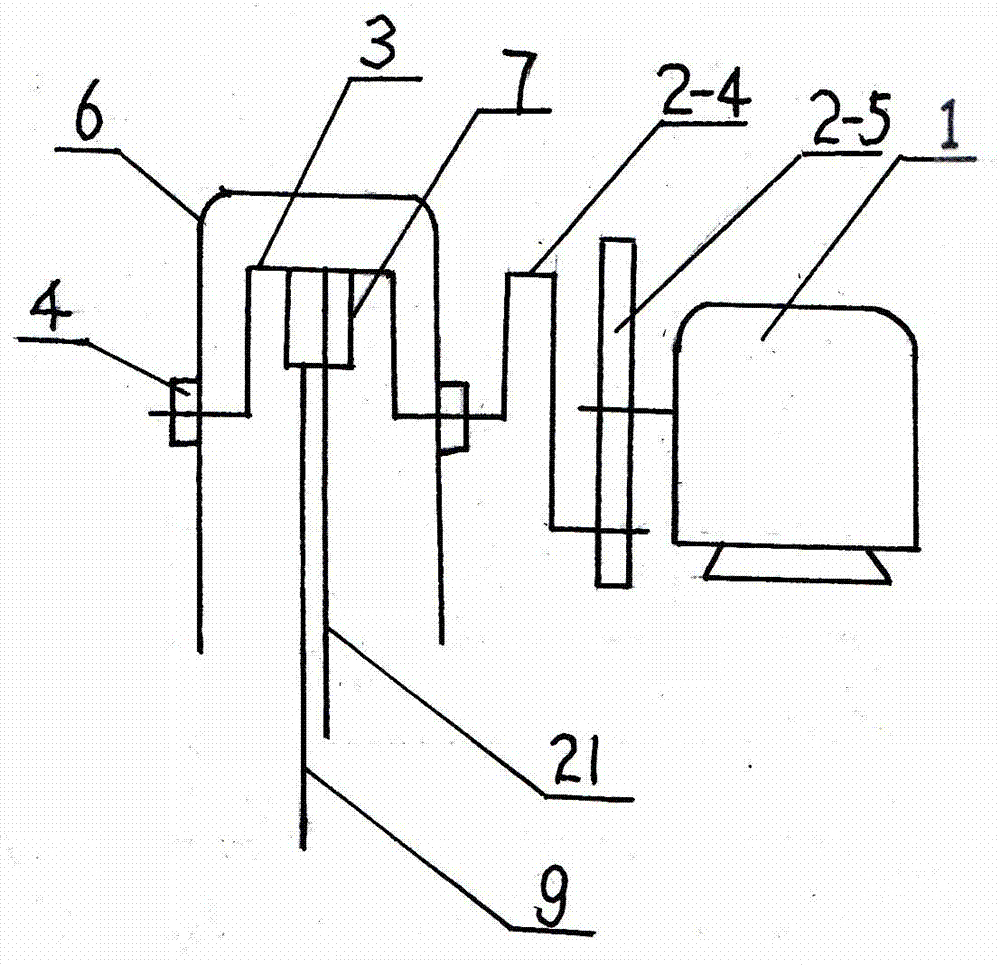

[0021] figure 1 The labels are: power machine 1, transmission part 2, driving crankshaft 3, front bearing seat 4, groove bracket 5, base 6, connecting piece 7, roller shaft 8, roller 8-1, power lever 9, double plate 9 -1. Lever fulcrum shaft 10, fork rod 11, rear bearing seat 12, driven crankshaft 13, pulley 14, belt 15, shift fork 16, shift fork fixed shaft 17, shift fork bracket 18, connecting screw 19, shift fork pull rod 20 , Crankshaft connecting rod 21.

[0022] see figure 1 , figure 2 , the double-lever power energy-saving device of the present invention comprises a power machine 1 and a double-lever power transmission mechanism, wherein the power machine 1 is a diesel engine or a gasoline engine or an electric motor, and the double-lever power transmission mechanism is composed of a base 6, a transmission member 2, a driving crankshaft 3, Front bearing seat 4, grooved support 5, roller shaft assembly, crankshaft connecting rod 21, power lever 9, shift fork assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com