Full stroke lifting worm structure

A lifting worm, full-stroke technology, applied to transmission parts, belts/chains/gears, mechanical equipment, etc., can solve the problem of falling off of the nut 3 and the dust-proof outer tube 4, limited fixed height of the workbench, and failure of the lifting worm mechanism and other problems to achieve the effect of avoiding the detachment of the dust-proof outer tube and the nut, improving stability and reliability, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

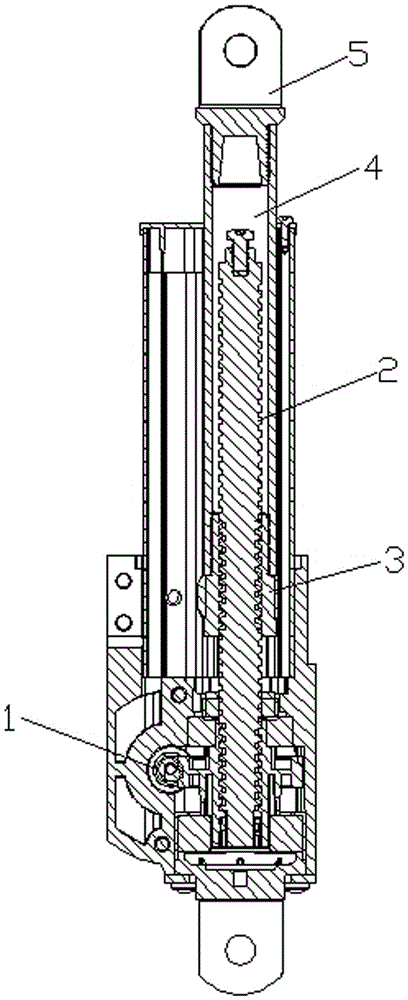

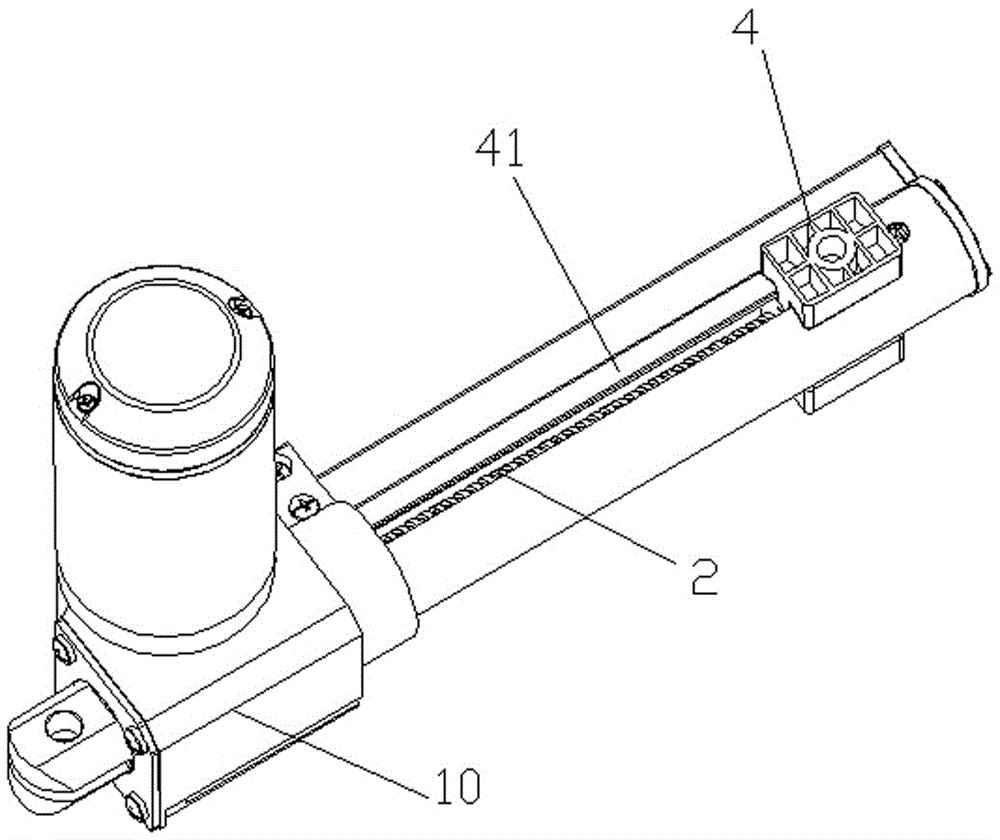

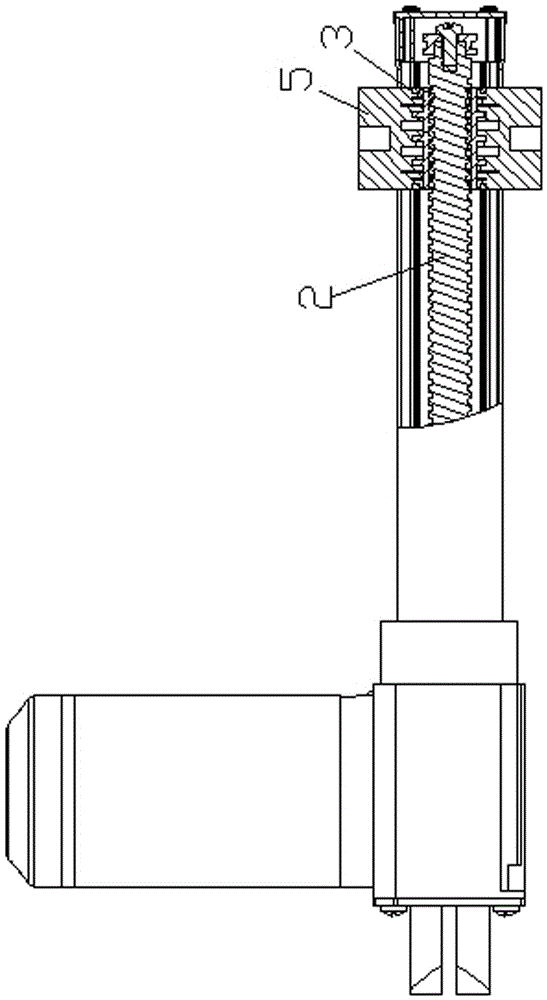

[0017] Such as figure 2 , 3 , 4, a full-stroke lifting worm structure, including a housing 10, a power source located in the housing 10, and a worm 2 driven by the power source to rotate and placed outside the housing 10, the worm 2 jacket A dust-proof outer tube 4 is established, one end of the dust-proof outer tube 4 is fixedly connected to the housing 10, and a limit opening groove 41 is provided on the dust-proof outer tube along its axial direction; A nut 3 is provided, and the nut 3 is connected to the worm screw 2 through threaded engagement. One end of the workbench fixing head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com