Preparation method of thermoplastic starch material based on non-grain woody vegetable oil

A thermoplastic starch and woody plant technology, applied in the field of biodegradable materials, can solve the problems of easily polluted packaging items, reduce the adverse effects of small molecule plasticizers, plasticizer migration, etc., and achieve low plasticizer migration, Fully degradable, performance controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

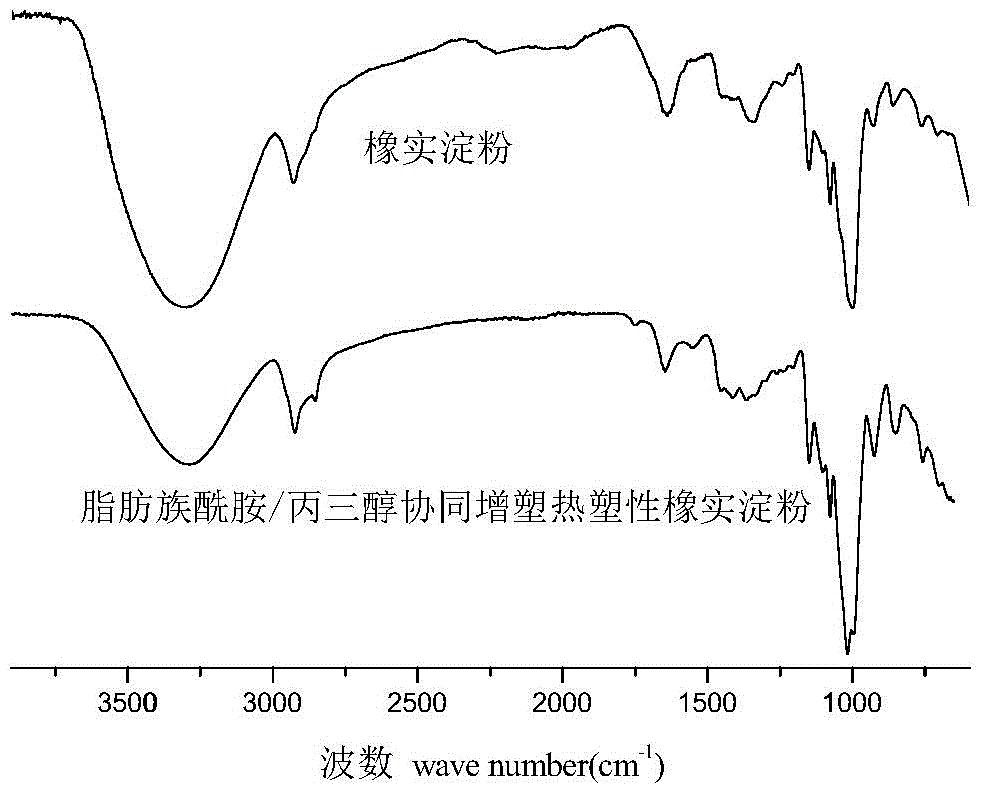

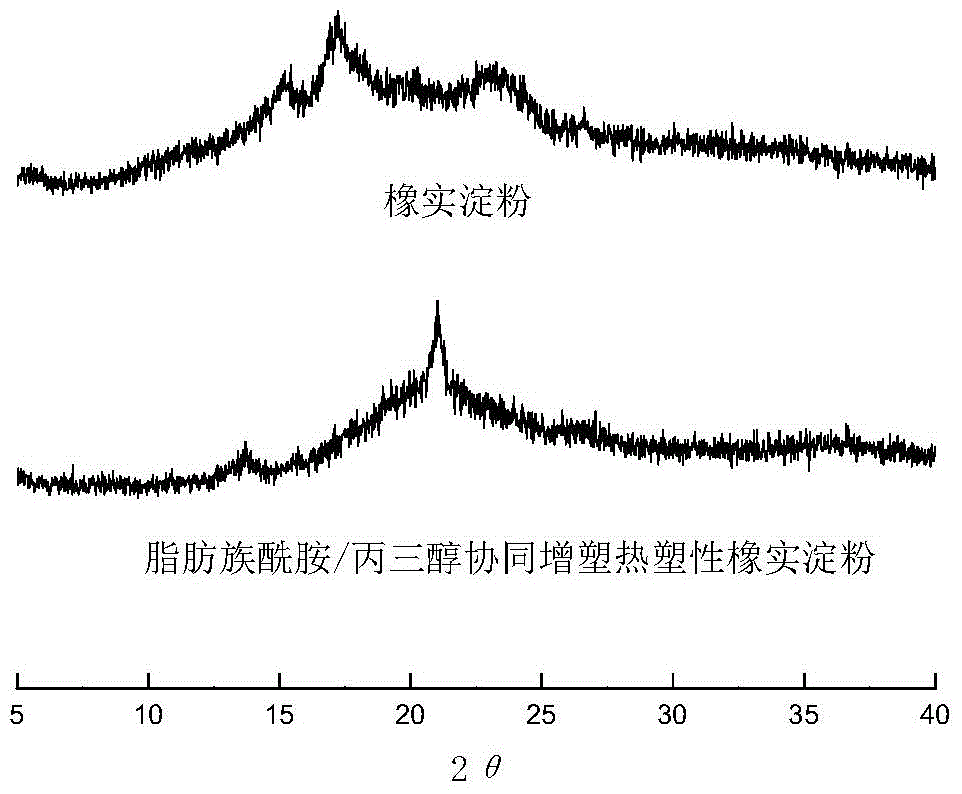

Embodiment 1

[0024] Stir the fatty acid and its derivatives, heat and control the temperature to 140°C, then add ethanolamine dropwise at a ratio of 1.1:1 to the carboxyl group of ricinoleic acid, and then add 0.25% of the catalyst 1-hydroxybenzotri azole, heated to 180°C, reacted for 4 hours, and distilled off unreacted ethanolamine under reduced pressure to obtain aliphatic amide plasticizer; the obtained aliphatic amide was mixed with glycerin and acorn starch according to the mass ratio of 10:30:70 The mixture was uniformly mixed, collected and sealed at room temperature for 36 hours, and finally processed at 100°C by twin-screw extrusion to obtain a thermoplastic starch material based on vegetable oil.

Embodiment 2

[0026] Stir the fatty acid and its derivatives, heat and control the temperature to 140~160°C, then add diethylenetriamine dropwise at a molar ratio of 1.4:1 to the carboxyl group of maleic castor oil, and then add 2.5% of the catalyst phosphoric acid in the total reaction system mass Triphenol ester, heated up to 220°C, reacted for 1h, and distilled off the unreacted diethylenetriamine under reduced pressure to obtain aliphatic amide plasticizer; prepared aliphatic amide with glycerol and acorn starch according to 25 :20:70 mass ratio, mixed evenly, collected and sealed at room temperature for 36 hours, and finally processed by twin-screw extrusion method at 160°C to obtain a thermoplastic starch material based on vegetable oil.

Embodiment 3

[0028] Stir the fatty acid and its derivatives, heat and control the temperature to 140~160°C, then add diethylenetriamine dropwise at a ratio of 1.2:1 to the carboxyl group of the dimerized fatty acid, and then add 0.5% of the catalyst imidazole in the total reaction system mass , heated up to 190°C, reacted for 3h, and removed unreacted diethylenetriamine under reduced pressure to obtain an aliphatic amide plasticizer; the prepared aliphatic amide, glycerol, acorn starch according to 50:10: The mass ratio of 70% was mixed evenly, and the material was collected and sealed at room temperature for 24 hours. Finally, a thermoplastic starch material based on vegetable oil was obtained by twin-screw extrusion at 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com