A kind of paper hydrophobic modifier, its preparation method and application

A hydrophobic modifier, paper technology, applied in the direction of paper, water repellent addition, chemical modification of natural resin, etc., can solve the problem that paper cannot be effectively hydrophobic for a long time, and achieve good mechanical strength, thermal stability, and production efficiency. The effect of high, high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Grind 50g of rosin (first grade) into powder, dissolve it in 300ml of isopropanol and put it into a 500ml three-necked flask equipped with a mechanical stirrer, reflux condenser and nitrogen inlet, then add 6.6g of sodium hydroxide and heat up to 60°C to keep the temperature After 30 minutes, 15.3 g of epichlorohydrin was added into the three-necked flask, and the temperature was raised to 80° C. for 6 hours. Washed with water, dried, and reduced pressure to obtain a light yellow viscous liquid. Weigh 50g of light yellow viscous liquid and 29.8g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and dissolve it in 350ml of N,N-dimethylformamide, stir well and add 0.3g of triphenylphosphine, heat up to 135°C for 4 hours, then add 34.1g of propyl triethoxysilane isocyanate, stir evenly, add 0.3g of dibutyltin dilaurate, continue to react for 6 hours, and remove the solvent by rotary evaporation A paper hydrophobic modifier is obtained.

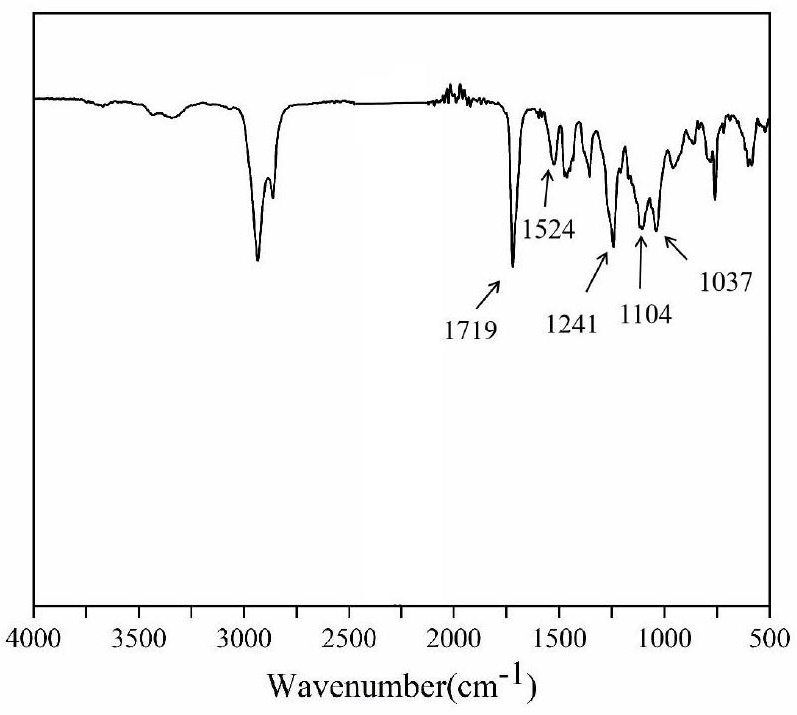

[0029] The infrared spectrum ...

Embodiment 2

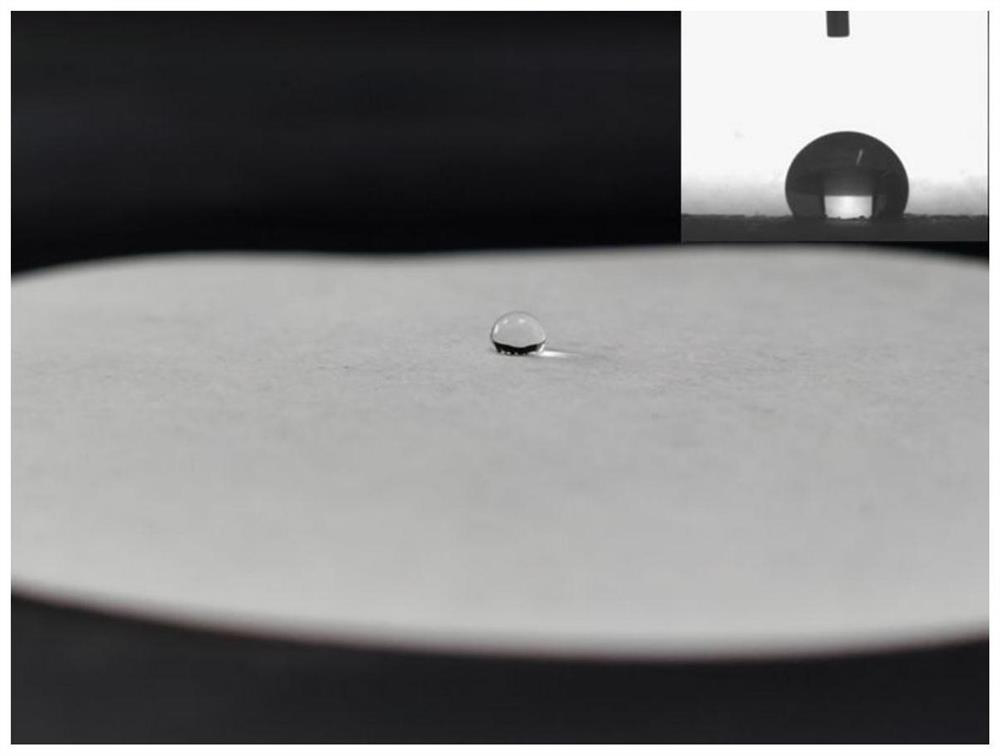

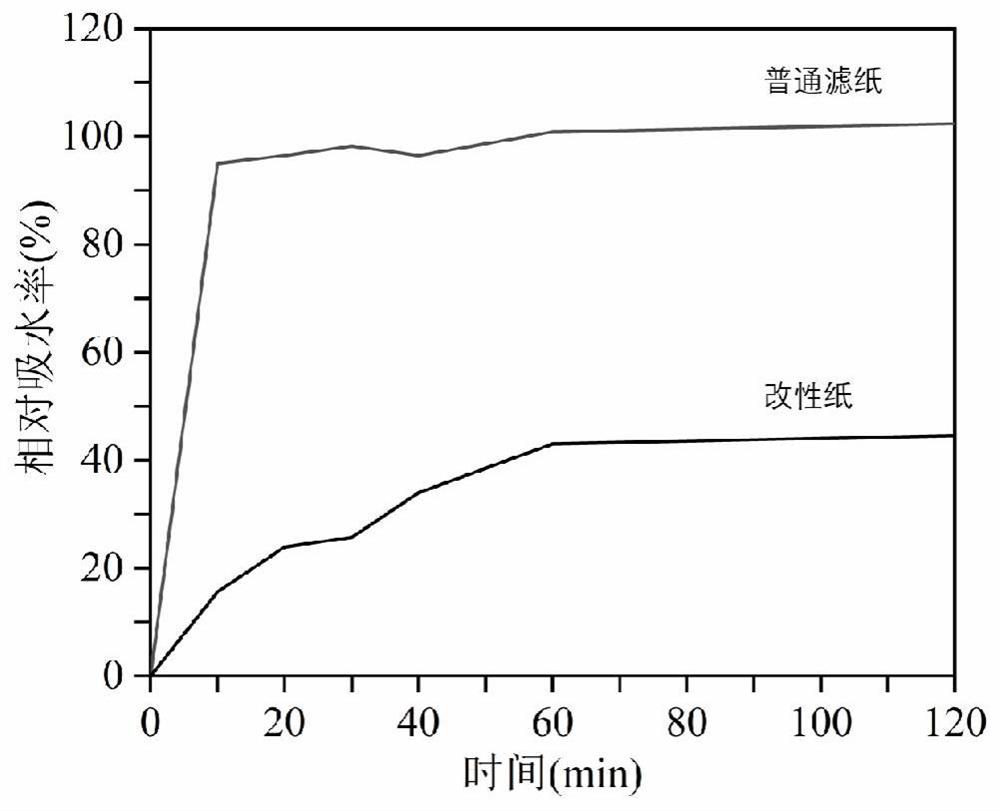

[0031] Weigh 1g of paper hydrophobic modifier and dissolve it in 19g of n-hexane, add dropwise 0.01g of deionized water and 0.003g of ammonia water (containing 25wt% ammonia) while stirring to form an emulsion, after standing for 2h, the paper (90mm slow qualitative Filter paper, thickness 0.3-0.5mm, Shanghai Aladdin) was soaked in the emulsion overnight, and then the paper was put into a hot press machine, and the pressure was 20MPa, and the temperature was 100°C, and hot pressing was performed for 1h to obtain hydrophobic paper.

Embodiment 3

[0033] Weigh 2g of paper hydrophobic modifier and dissolve it in 18g of n-hexane, add dropwise 0.02g of deionized water and 0.006g of ammonia water (containing ammonia 25wt%) while stirring to form an emulsion, and after standing for 2h, the paper (90mm slow speed qualitative Filter paper, thickness 0.3-0.5mm, Shanghai Aladdin) was soaked in the emulsion overnight, and then the paper was put into a hot press machine, and the pressure was 20MPa, and the temperature was 100°C, and hot pressing was performed for 1h to obtain hydrophobic paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com