Method for judging pot size for induction cooker and induction cooker

A technology of pot size and induction cooker, applied in the field of induction cooker, can solve the problems of misjudgment of induction cooker, power adjustment and heating of induction cooker, inaccurate detection results, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

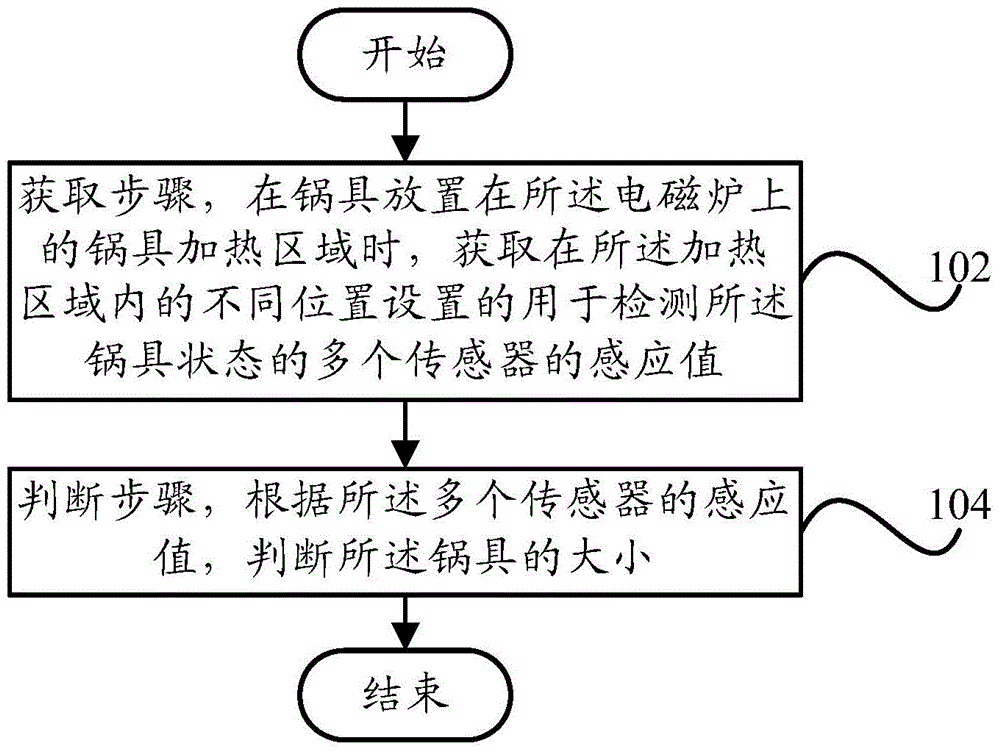

Embodiment approach 1

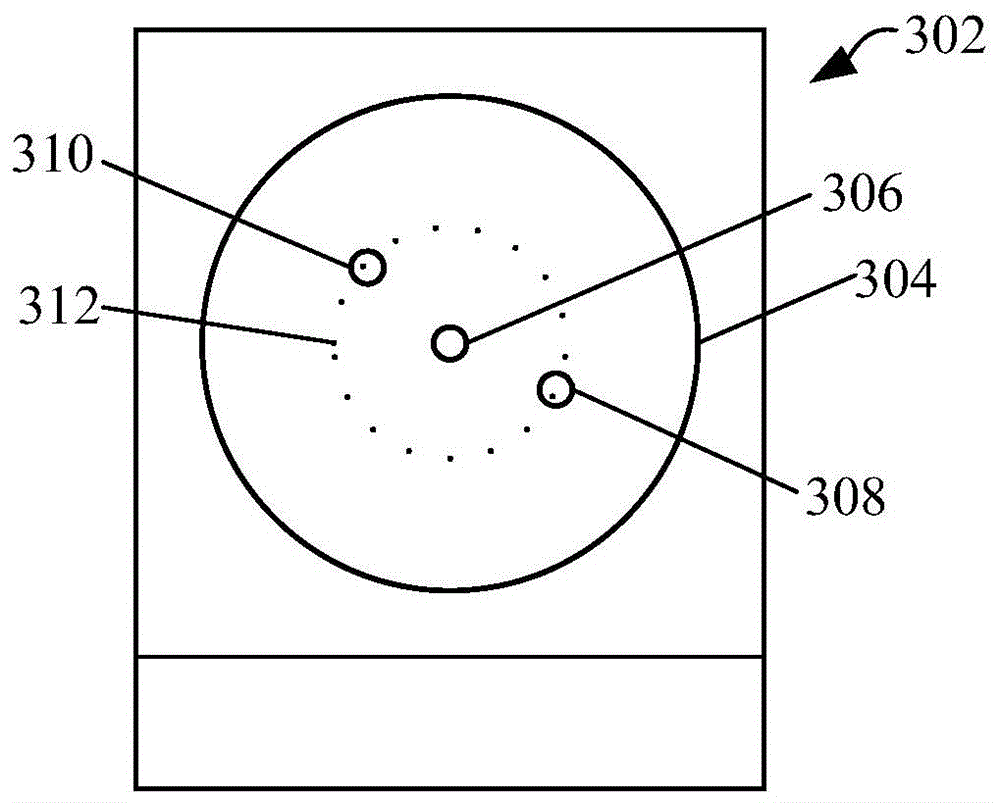

[0079] Such as Figure 3A As shown, a sensor 306 is set at the center point in the pot heating area 304 on the induction cooker panel 302, and set on the circumference 312 of the first circular area with the center point as the center and the first preset distance as the radius at least one sensor, Figure 3A There are two sensors, namely sensor 308 and sensor 310 . Wherein, the first preset distance may be the critical radius of a standard small pot, such as 30 mm, to determine whether the pot is a small pot.

Embodiment approach 2

[0081] Such as Figure 3B As shown, a sensor 306 is set at the center point in the pot heating area 304 on the induction cooker panel 302, and set on the circumference 312 of the first circular area with the center point as the center and the first preset distance as the radius at least one sensor, Figure 3A There are two sensors, namely sensor 308 and sensor 310, and one sensor 314 is set inside the first circular area. Wherein, the first preset distance may be the critical radius of a standard small pot, such as 30 mm, to determine whether the pot is a small pot.

[0082] Certainly, the number of sensors arranged inside the first circular area may be any number, and the positions may also be set arbitrarily, for example, the sensor 314 may only be arranged inside the first circular area.

Embodiment approach 3

[0084] Such as Figure 3C shown in Figure 3A On the basis of the setting method, at least one sensor is set on the circumference 316 of the second circular area with the center point as the center and the second preset distance as the radius, Figure 3C Only one sensor 318 is provided on the circumference 316 of the second circular area. Wherein, the first preset distance can be the critical radius of a standard small pot, such as 30mm, to determine whether the pot is a small pot, and the second preset distance can be the critical radius of a standard large pot, such as 50mm , to determine whether the pot is a large pot, and whether it is between a large pot and a small pot.

[0085] Of course, in order to judge the size of the pot more accurately, a plurality of sensors can be set at different distances from the center of the pot heating area in the pot heating area, so as to detect the The obtained value judges the size of the pot.

[0086] In addition, the technical so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com