Method for cooling and purifying bus stop through electrostatic spraying

A bus station, electrostatic spray technology, applied in the field of daily life, can solve problems such as large impact, limited effect, poor effect, etc., and achieve the effects of improving the environment, good cooling effect, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

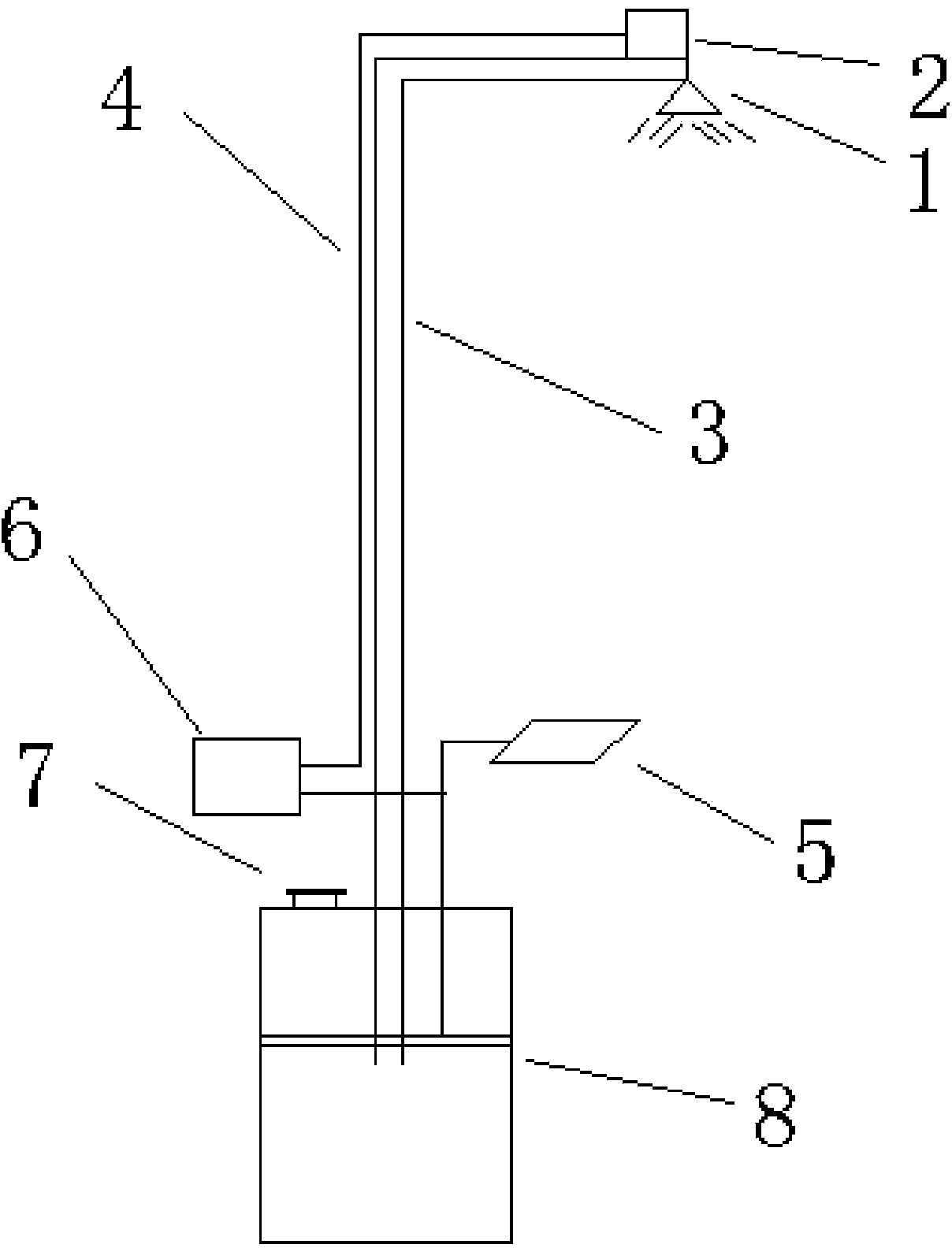

[0021] Below in conjunction with accompanying drawing, the method for electrostatic spray cooling and purification of the bus stop involved in the present invention is described in detail.

[0022]

[0023] like figure 1 Shown is an explanatory diagram of the electrostatic spray dust removal system involved in the method of the present invention. The electrostatic spray dedusting system is installed on the bus platform, the liquid storage tank 8 is hidden under the ground of the column of the bus platform, the top of the liquid storage tank 8 is provided with a liquid inlet 7, and the liquid is injected into the liquid storage tank 8 through the liquid inlet 7. Top up with water. In this embodiment, the pressurizing device 5 is a foot pedal, which is placed on the column, and the nozzle 1 is installed on the edge of the column canopy, and the direction is downward. By pressing the foot pedal 5, the water in the liquid storage tank 8 is transported to the nozzle 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com