Small-flow ultrasonic flowmeter error estimation method based on flow lines

An ultrasonic flowmeter and small flow technology, applied in the direction of liquid/fluid solid measurement, measuring devices, instruments, etc., can solve the problems of increasing the cost of flowmeters, less research on monophonic ultrasonic flowmeters, and measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] A streamline-based error estimation method for a small-flow ultrasonic flowmeter, the method includes the following steps:

[0037] (1) According to the actual structure of the small-diameter, small-flow ultrasonic flowmeter, the simulation analysis and modeling are carried out. The modeling process is as follows:

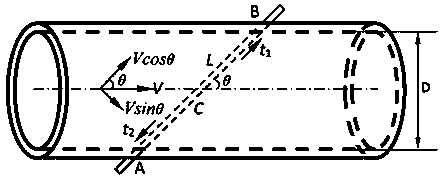

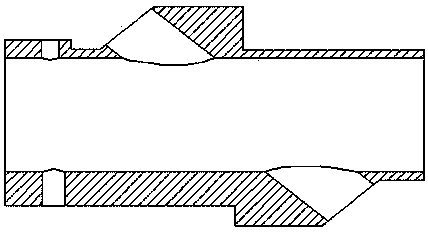

[0038] (a) Use Gambit pre-processing software or 3D CAD software to establish the geometric model of the flowmeter. Pipe inner diameter D , there is a through hole in the direction of 45 degrees to the axis of the pipeline, the transducer is installed, and the pressure and temperature sensors are respectively placed in the upper and lower holes on the left side, for example figure 2 shown.

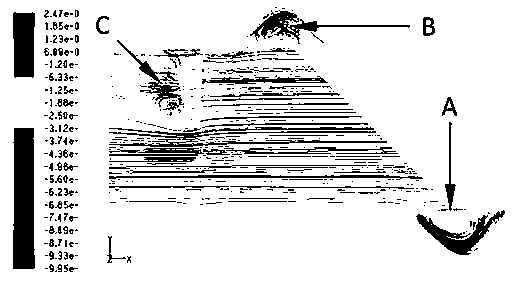

[0039] (b) Mesh the model. Since the pipeline has a through-hole structure for installing transducers and sensors, the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com