Biological and mechanical wear testing machine

A wear test and biomechanics technology, applied in the direction of testing wear resistance, etc., can solve the problems of insufficient automation of the test process and insufficient scientific and reasonable test results, and achieve the effect of more automated test process and scientific and reasonable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

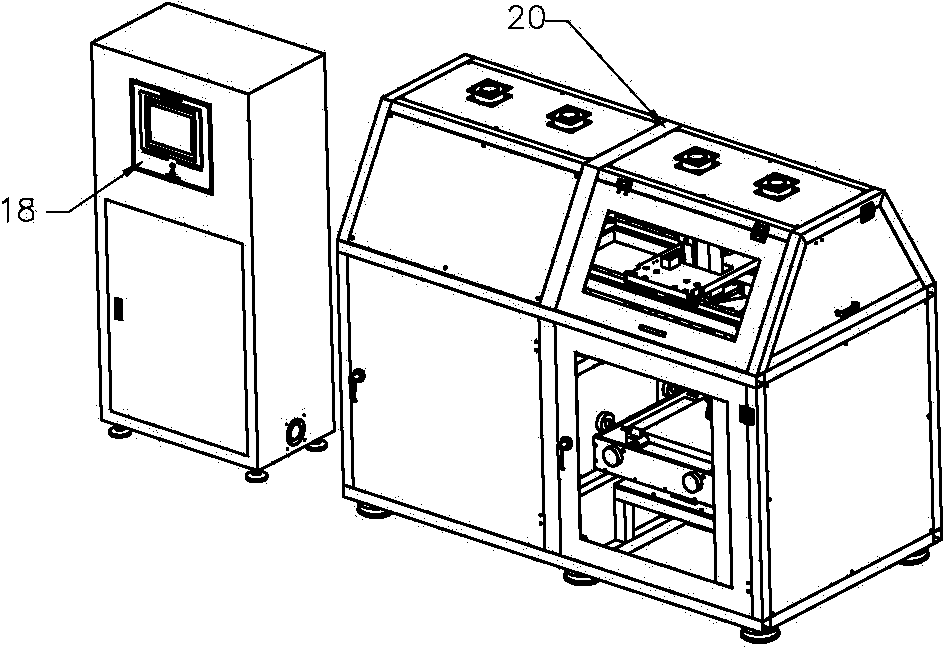

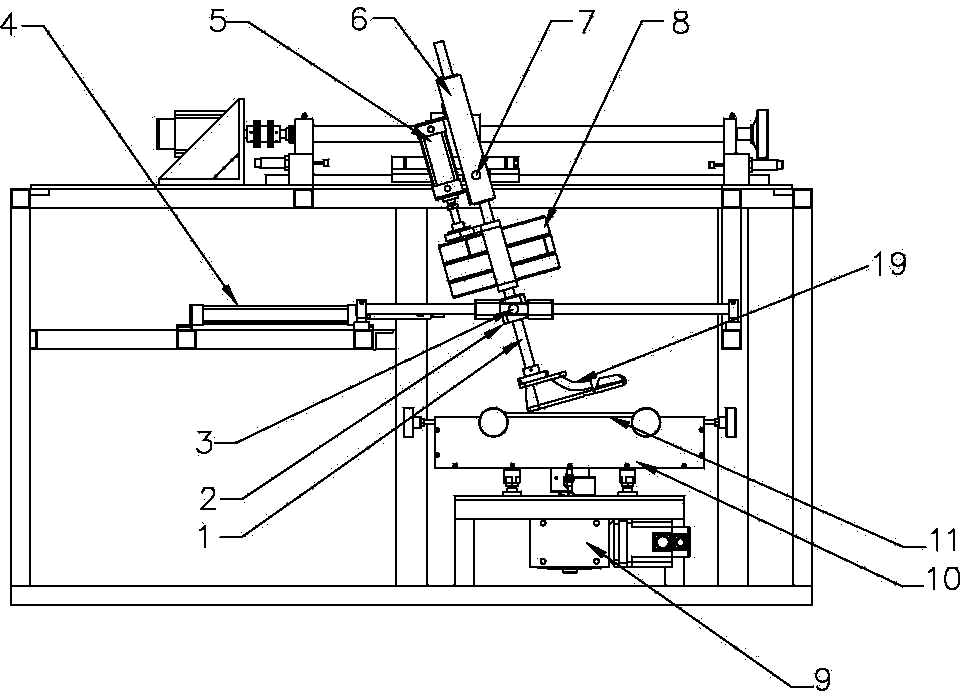

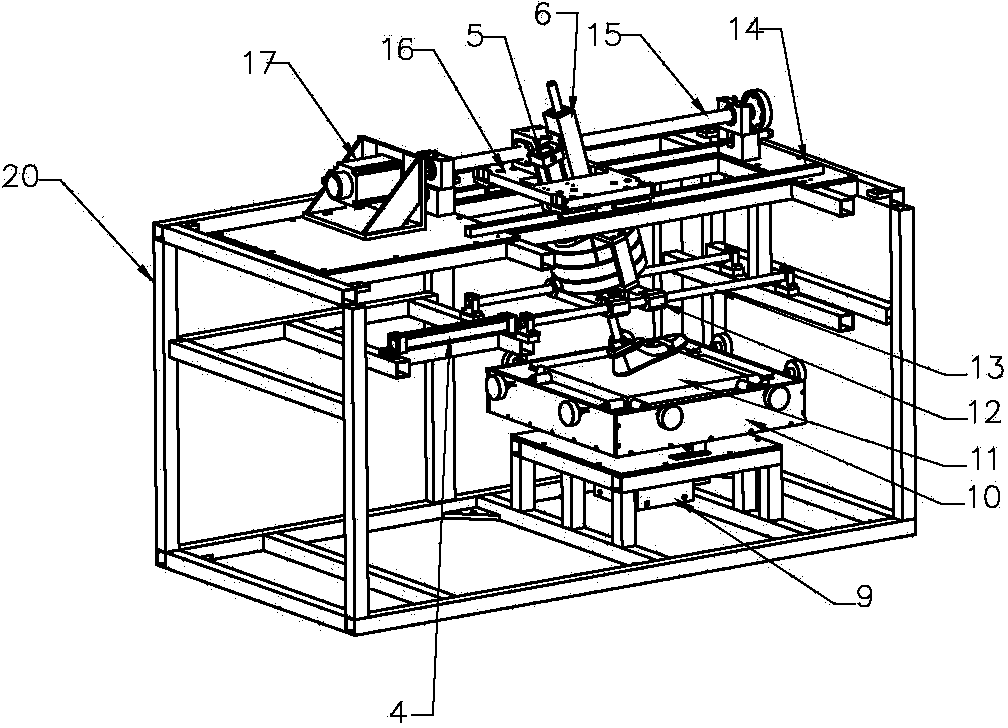

[0015] as attached figure 1 to attach image 3 As shown, the biomechanical wear testing machine of the present invention has a structure as follows: it includes a touch screen 18 for setting the number of tests, test time and motion parameters, and it also includes a frame 20, and the touch screen 18 is arranged on the side of the frame 20 ; The frame 20 is provided with an upper sliding seat 16, a lower sliding seat 12, an upper rotating block 6, a lower rotating block 2, a sliding drive motor 17, a first screw mandrel 15, a first cylinder 5, a second cylinder 4, an analog pin And the rotary table 10, the rotary table 10 is placed with a wear plate 11; the upper slide 16 and the lower slide 12 can move left and right along the frame 20; the slide drive motor 17 drives and connects the first screw mandrel 15, the first The screw mandrel 15 is threadedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com