Method for monitoring two-dimensional seepage in large-scale single-fractured medium

A single-crack, large-scale technology, applied in the direction of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems that affect the accuracy of measurement results, small scale, inaccurate use of permeability parameters, etc., to achieve Accurate and reliable measurement results, convenient operation and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for monitoring two-dimensional seepage in a large-scale single-crack medium of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0031] A method for monitoring two-dimensional seepage in a large-scale single-crack medium of the present invention comprises the following steps:

[0032] step 1

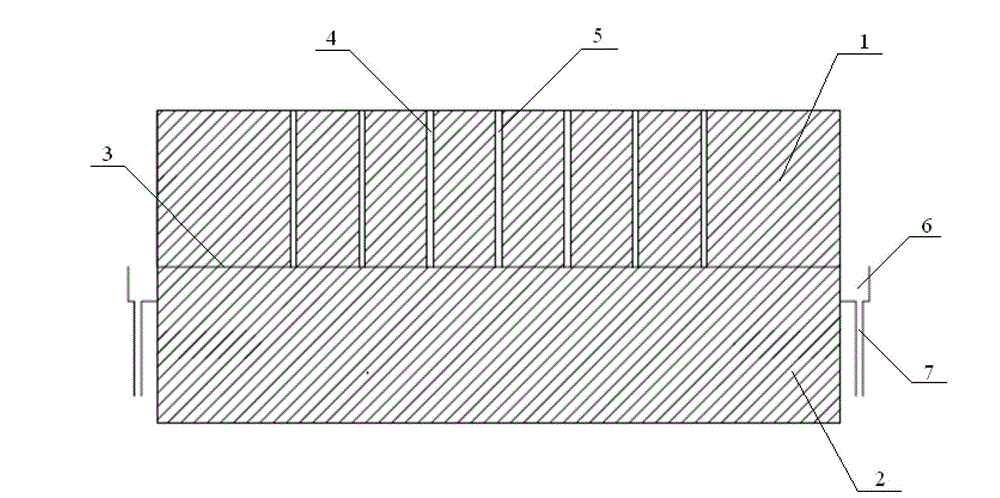

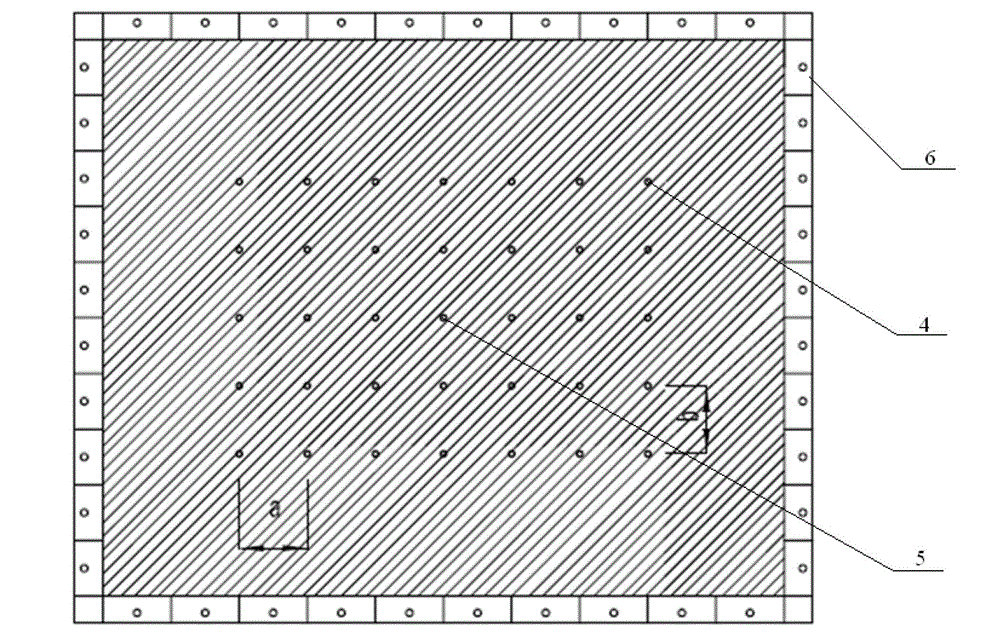

[0033] The large-scale fractured medium was cut along the fracture surface, and the surfaces were polished respectively to form a horizontal fracture surface 3, and two cubic samples with the same shape and size were obtained: upper sample 1 and lower sample 2. The four corners of the upper sample 1 and the lower sample 2 are aligned and stacked vertically.

[0034] In this embodiment, the maximum dimensions of the upper sample 1 and the lower sample 2 are both larger than 1 meter, which is a meter-level scale. The maximum scale is a term in the field, which means the maximum value of the length, wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com